Mesh width continuous adjustment filter screen with vibration function and continuous adjustment method

A technology of grid width and filter screen, applied in the fields of precision instruments and machinery, can solve the problem of not finding the filter screen, etc., to improve the filtering effect, realize the adjustment of grid width, and achieve good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028] This embodiment is an embodiment of the mesh width continuously adjustable filter screen with vibration function.

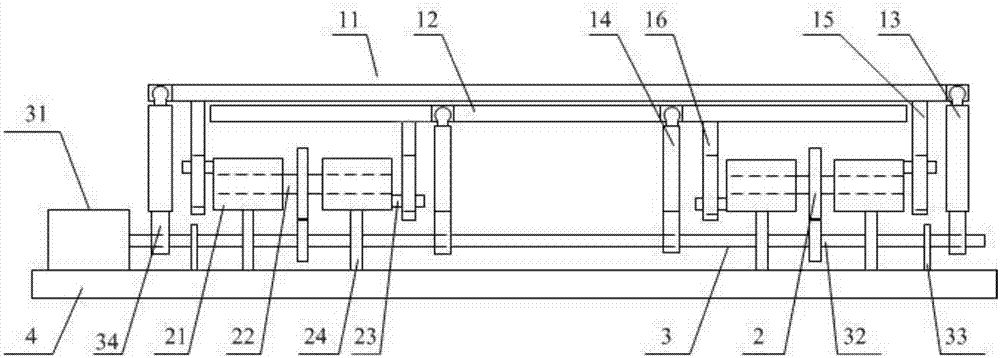

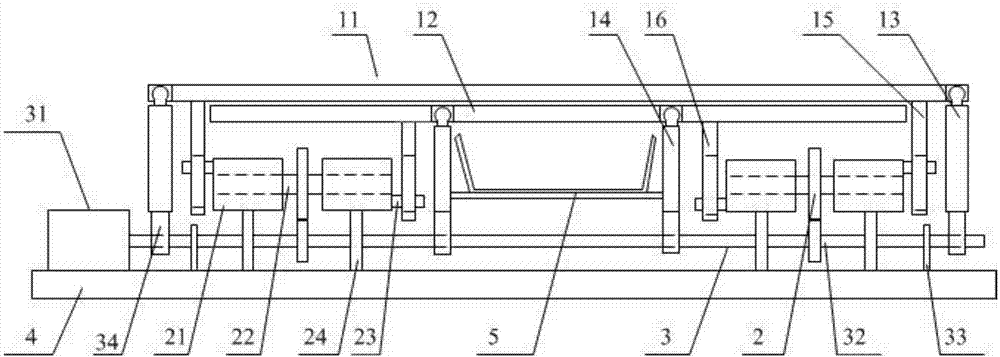

[0029] The mesh width continuously adjustable filter screen with vibration function in this embodiment, the structural diagram is as follows figure 1 shown. The grid width continuously adjusting filter screen with vibrating function includes a first one-dimensional filter screen 11 and a second one-dimensional filter screen 12 with the same cycle set up and down, and a duty cycle of 50%. The net 11 and the second one-dimensional filter screen 12 perform reverse motion and vibrate up and down simultaneously under the adjustment of the filter screen adjustment mechanism 2, and the filter screen adjustment mechanism 2 is powered by the power transmission device 3 installed on the base 4;

[0030] The first one-dimensional filter screen 11 is installed between two first supports 13 through a linear bearing, and the linear bearing can ensure that the first one...

specific Embodiment 2

[0033] This embodiment is an embodiment of the mesh width continuously adjustable filter screen with vibration function.

[0034] The mesh width continuous adjustment filter screen with vibration function of this embodiment is further defined on the basis of specific embodiment one:

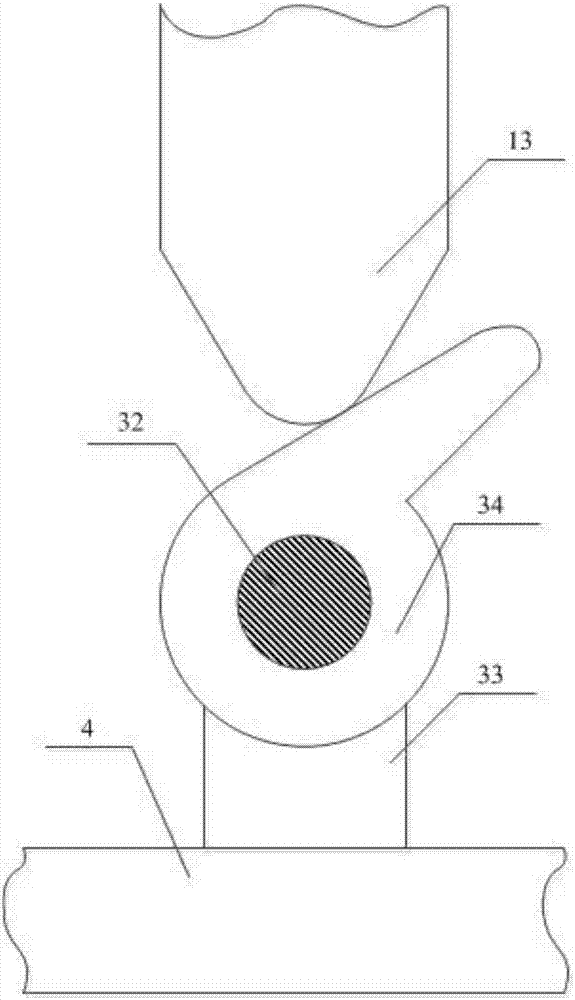

[0035] The swivel 21 is supported by a swivel bracket 24 installed on the base 4. The specific structure is: the bearing connection between the swivel 21 and the swivel bracket 24, the swivel 21 is interference fit with the inner ring of the bearing, and the swivel bracket 24 is connected to the bearing. The outer ring is fixedly connected;

[0036] The transmission rod 32 is supported by the transmission bracket 33 installed on the base 4. The specific structure is: the bearing connection between the transmission rod 32 and the transmission bracket 33, the transmission rod 32 and the inner ring of the bearing have an interference fit, and the transmission bracket 33 is fixed to the outer ring of...

specific Embodiment 3

[0037] This embodiment is an embodiment of the mesh width continuously adjustable filter screen with vibration function.

[0038] The mesh width continuous adjustment filter screen with vibration function of this embodiment is further defined on the basis of the specific embodiment one: the bottoms of the first support 13 and the second support 14 are all provided with rollers, the first support 13 and the second support Rolling friction is formed between the two brackets 14 and the cam 34 .

[0039] This structural limitation can reduce wear between the first bracket 13 and the second bracket 14 and the cam 34 , thereby improving the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com