Disassembling jig

A jig and box technology, applied in the direction of manufacturing tools, welding/welding/cutting items, metal processing, etc., can solve the problems of product damage and low efficiency, and achieve the effect of balancing the tensile force and ensuring the quality of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

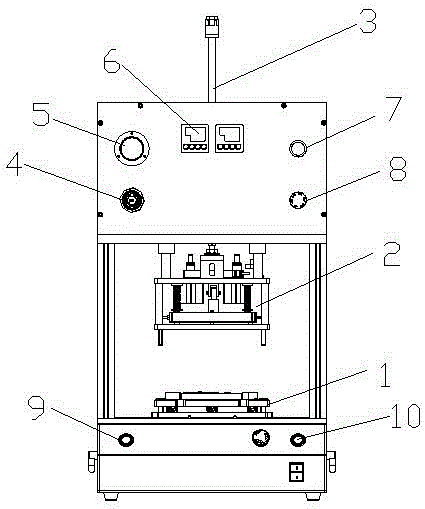

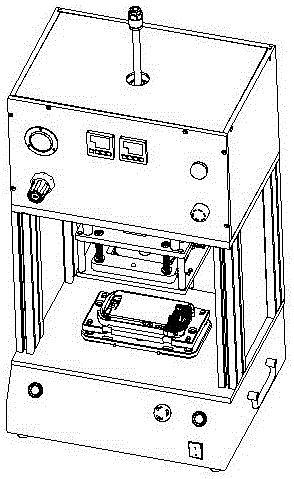

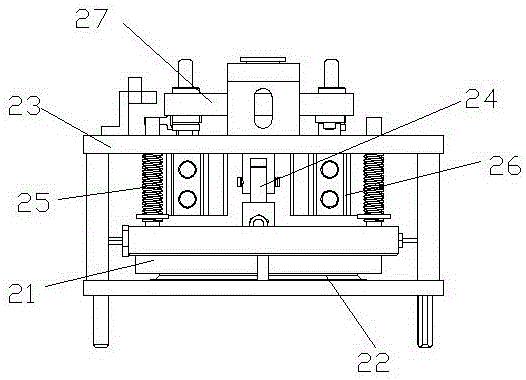

[0017] like Figure 1-Figure 4 As shown, a dismantling jig includes a box, the lower end of the box is provided with a fixed seat 1 for placing products, and a dismantling mechanism 2 that can move up and down is provided directly above the fixed seat 1. The dismantling mechanism 2 includes a heating platen 21 and a suction cup 22 that can pass through the platen and move up and down relative to it. After the product is fixed by the heating platen, it is heated, and then the shell is sucked by the suction cup and then pulled up to separate it from the whole machine to realize disassembly, which is quick and easy.

[0018] In this embodiment, a support plate 23 is provided above the heating platen 21, a moving plate 27 is provided above the support plate 23, and the suction cup 22 is connected by a fish-eye bearing 24 passing through the support plate 23. On the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com