Manual-automatic integrated tooling for assembling and disassembling break-brake spring

An opening spring, integrated technology, applied in the field of manual and automatic tooling, can solve the problems of slow assembly efficiency, uncommon labor intensity, affecting the production progress of products, etc., to reduce labor costs, reduce labor intensity of workers, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

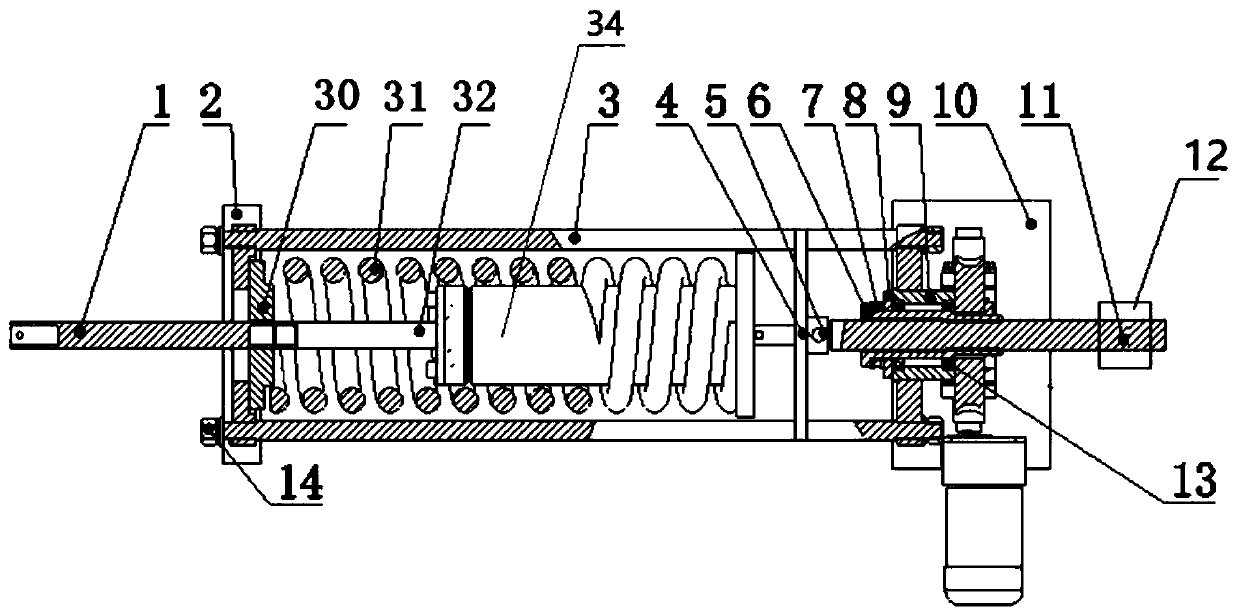

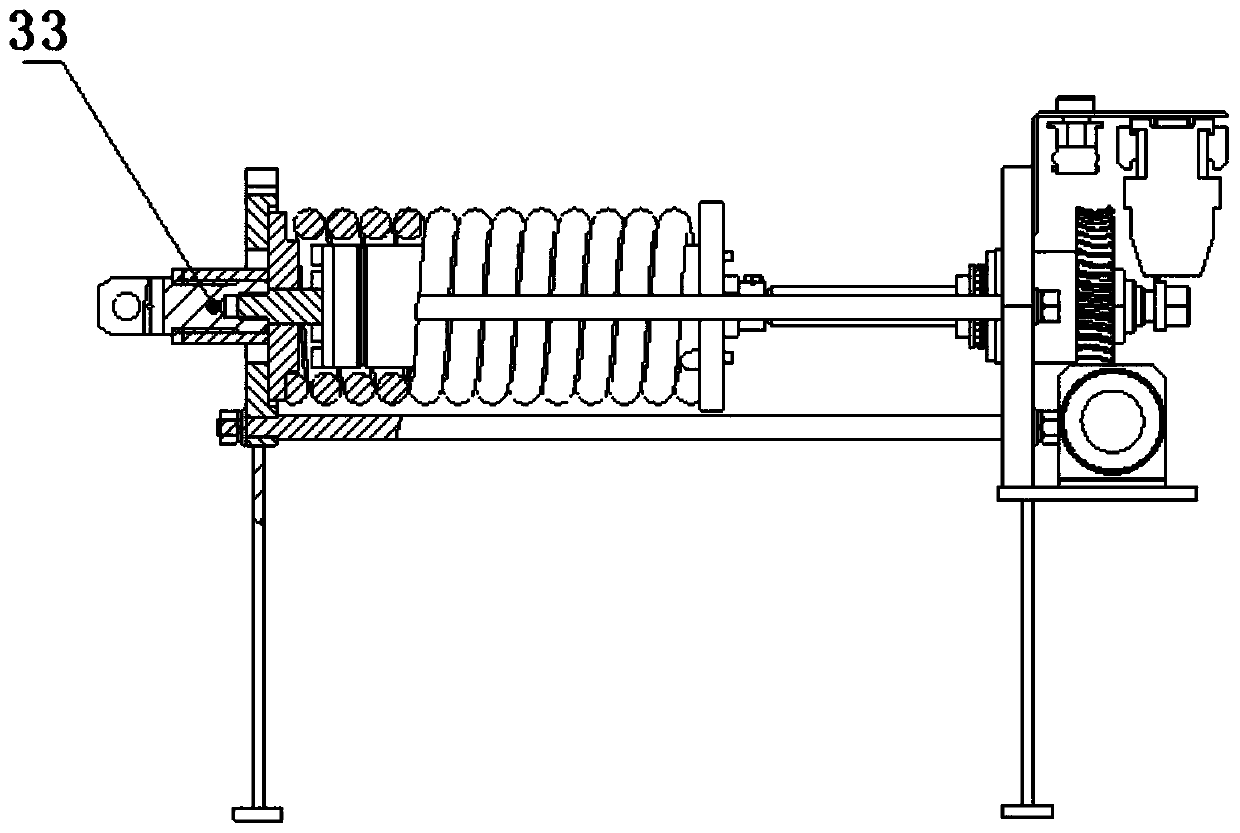

[0029] see Figure 1-Figure 3 , an automatic manual tool for assembling and disassembling the opening spring, including a manual control part and an automatic control part, the automatic control part includes a support frame, a transmission part, a guide rod 1 and a control element, the support frame The assembly part 34 is fixed on the top, the transmission part realizes the horizontal forward and backward movement of the screw rod 11, and the control element controls the transmission part; the manual part includes the screw rod 11, and the screw rod 11 is equipped with a manual control device.

[0030] The assembly part 34 includes a pressing block 30 , an opening spring 31 and a pull rod 32 , and the pull rod 32 is expandable to realize the compression and expansion of the opening spring 31 .

[0031] The support frame includes a left support plate 2 , a right support plate 10 and a guide column 3 , and the left support plate 2 and the right support plate 10 are tightly con...

Embodiment 2

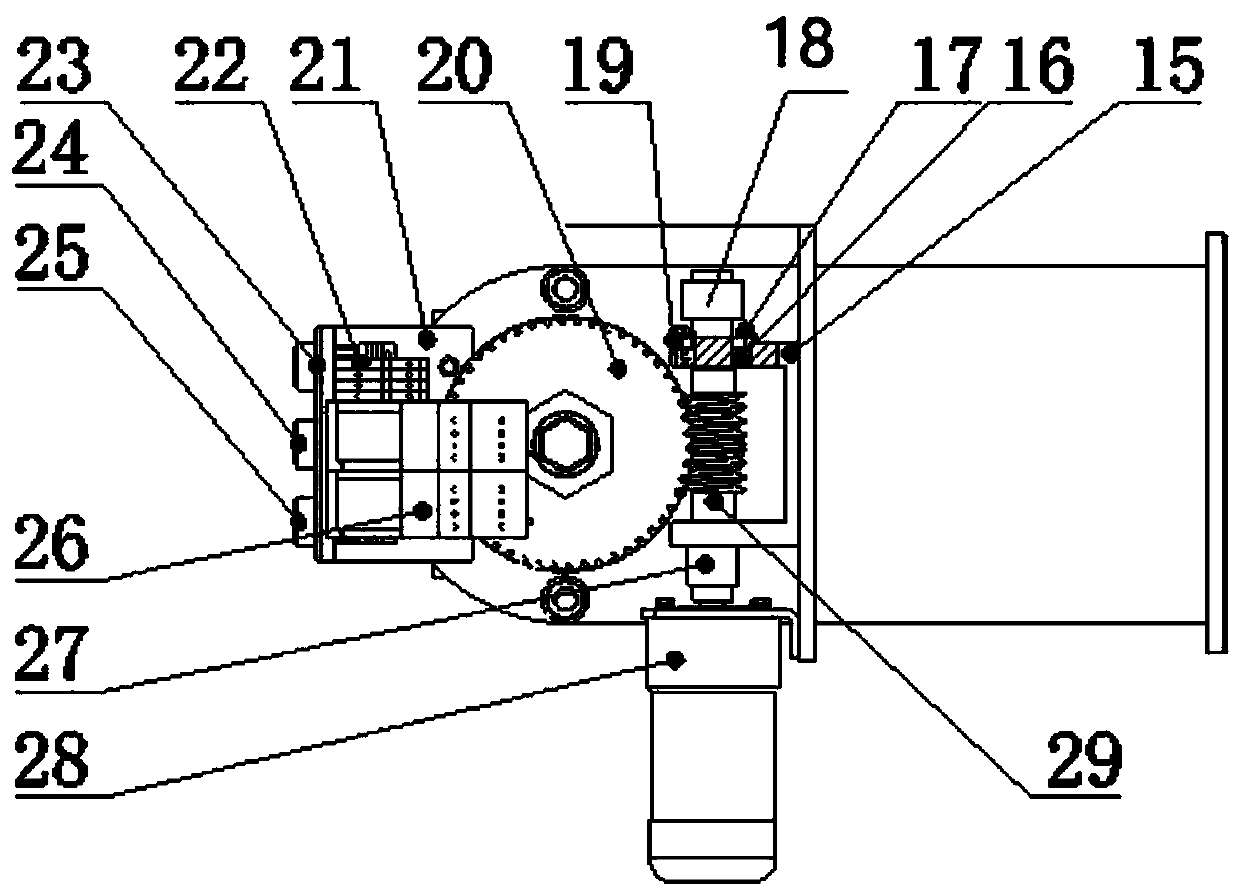

[0041] Such as figure 1 As shown, the difference from Embodiment 1 is that one end of the worm 29 is provided with a ratchet sleeve 18, and the ratchet sleeve 18 rotates while pushing the worm 29 to rotate, and the worm 29 drives the turbine 20 to rotate, and drives the turbine 20 to rotate while the turbine 20 rotates. The sleeve 6 rotates, and the screw rod 11 moves back and forth horizontally under the positioning of the pressing plate 4, so as to realize the manual compression of the opening spring 31.

[0042] The automatic manual tooling of the present invention is safe to use, simple and convenient to operate, greatly improves work efficiency, only needs one worker to operate, and greatly reduces labor costs and labor intensity of workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com