An integrated device for retrieving and assembling seal rings

A sealing ring and material head technology, which is used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inappropriate grasping of the sealing ring, difficulty in maintaining a circular shape, and difficulty in precise positioning of the sealing ring, so as to increase assembly. Difficulty, improve assembly efficiency, stable and reliable grasping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

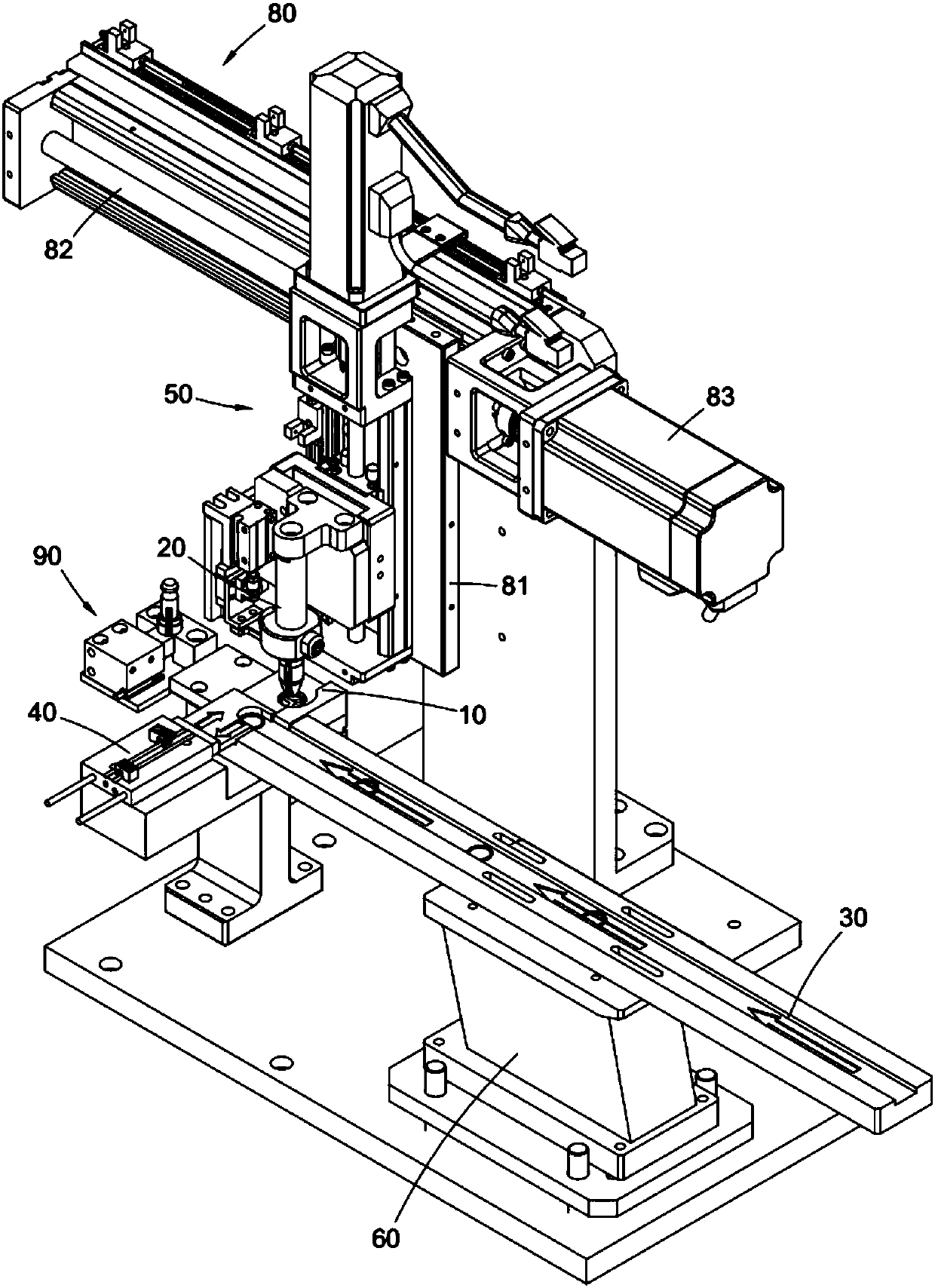

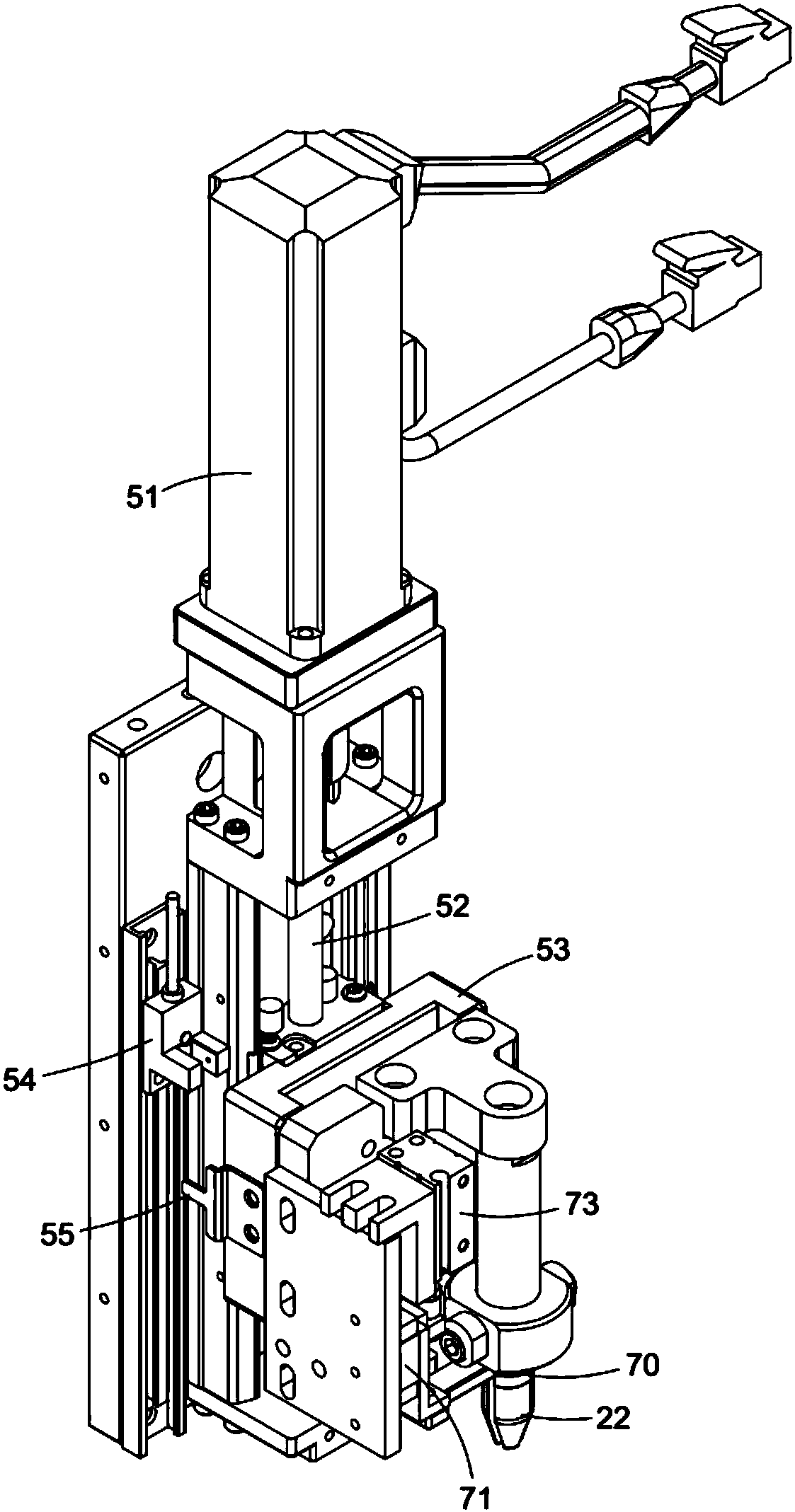

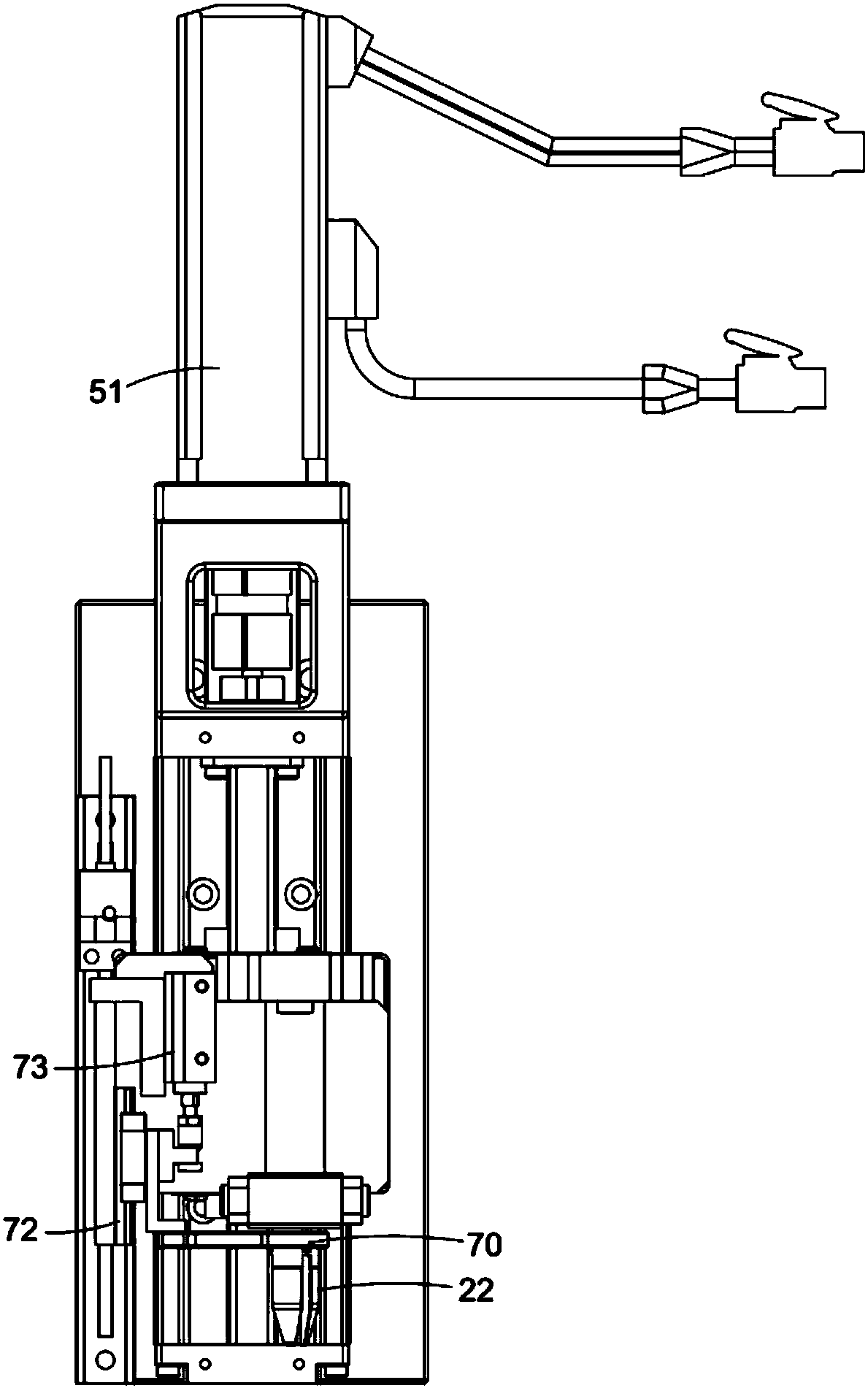

[0045] like figure 1 , an integrated device for retrieving and assembling sealing rings, including a feeding flow channel 30 , a distributing mechanism 40 , a retrieving station 10 , a retrieving assembly 20 , and a retrieving head transfer station 90 .

[0046] like figure 1 , the feeding channel 30 is installed on the feeding vibrating mechanism 60 .

[0047] like figure 1 , the distributing mechanism 40 and the reclaiming station 10 are respectively located on both sides of the end of the feeding flow channel 30 . The material distributing mechanism 40 moves the sealing ring on the material feeding channel 30 to the material reclaiming station 10 laterally.

[0048] combine Figure 4 , Figure 5 , the material distributing mechanism 40 includes a material distributing cylinder 41, a material distributing fork 42 installed on the material distributing cylinder, and a semicircular gap 420 is provided on the material distributing fork for receiving the sealing ring on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com