Assembly device for a sealing ring

A technology for assembling devices and sealing rings, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the difficulty of assembling small-diameter sealing rings, and achieve the effects of increasing assembly difficulty, improving assembly efficiency, and efficient and stable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

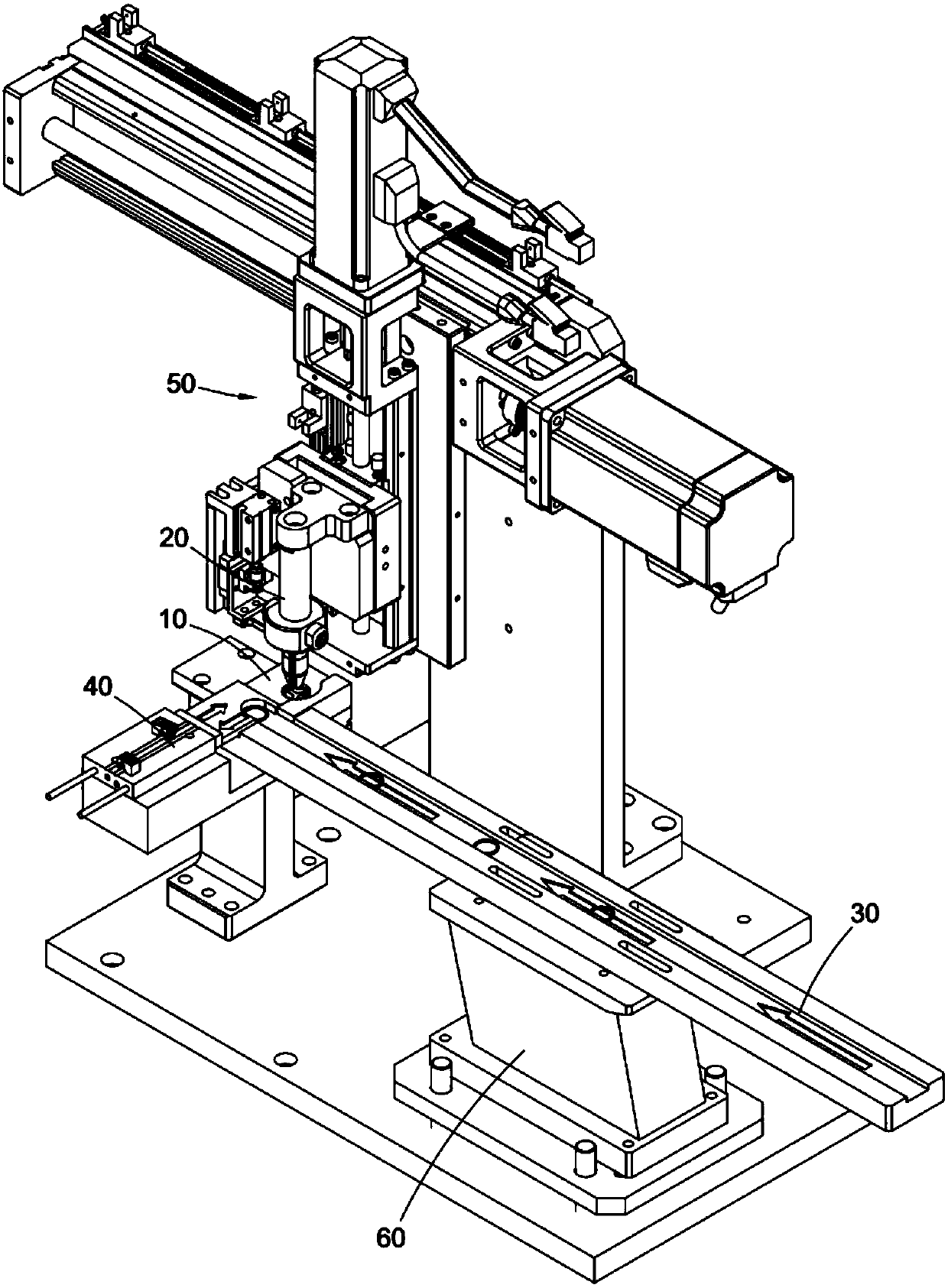

[0036] like figure 1 , an assembly device of a sealing ring, including a feeding flow channel 30 , a material distribution mechanism 40 , a reclaiming station 10 and an assembly assembly 20 .

[0037] like figure 1 , the feeding flow channel 30 is installed on the feeding vibration mechanism 60 .

[0038] like figure 1 , the material distribution mechanism 40 and the material reclaiming station 10 are respectively located on both sides of the end of the upper material flow channel 30 . The material distribution mechanism 40 laterally pushes the sealing ring on the upper material flow channel 30 to the material reclaiming station 10 .

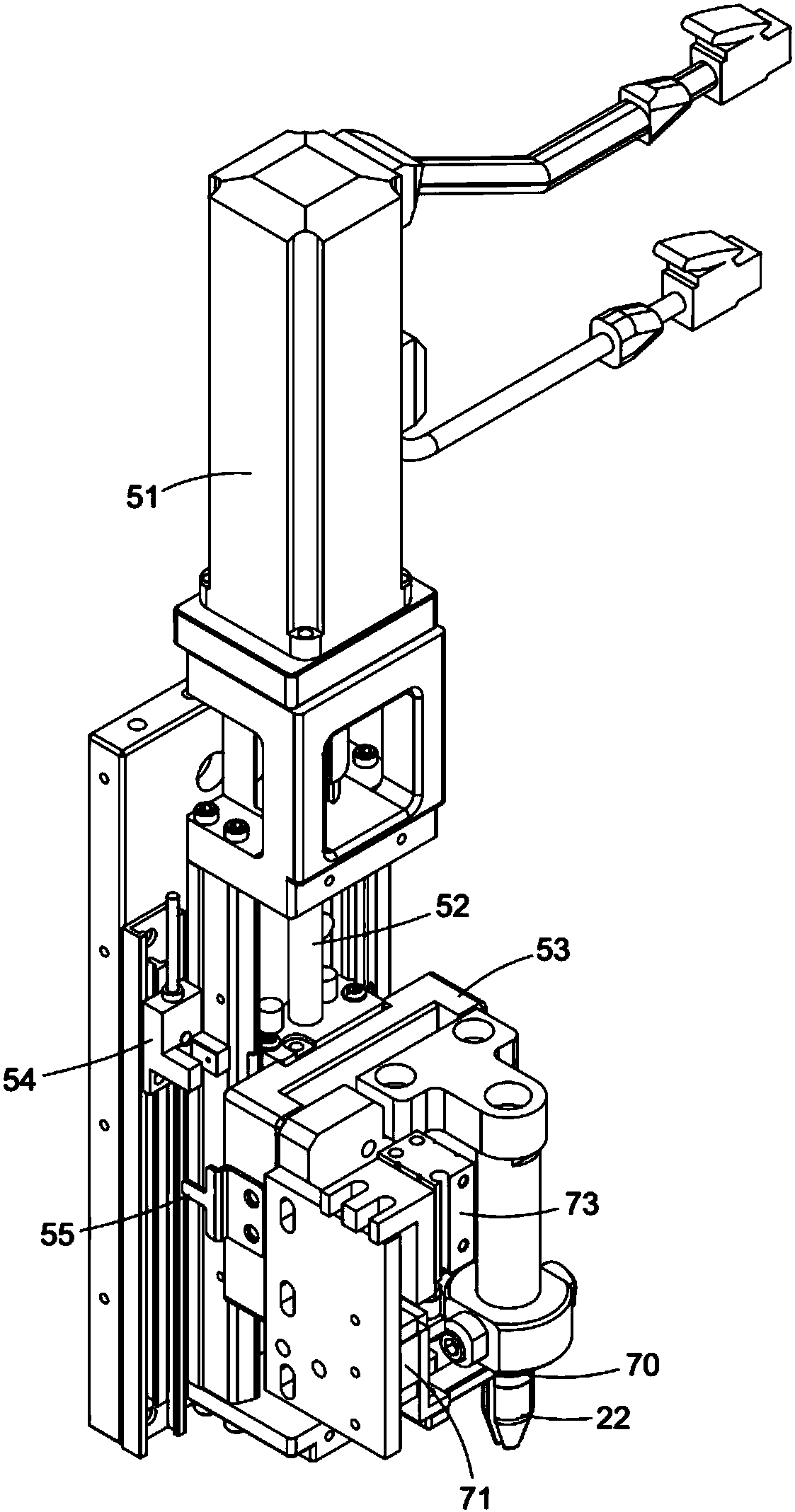

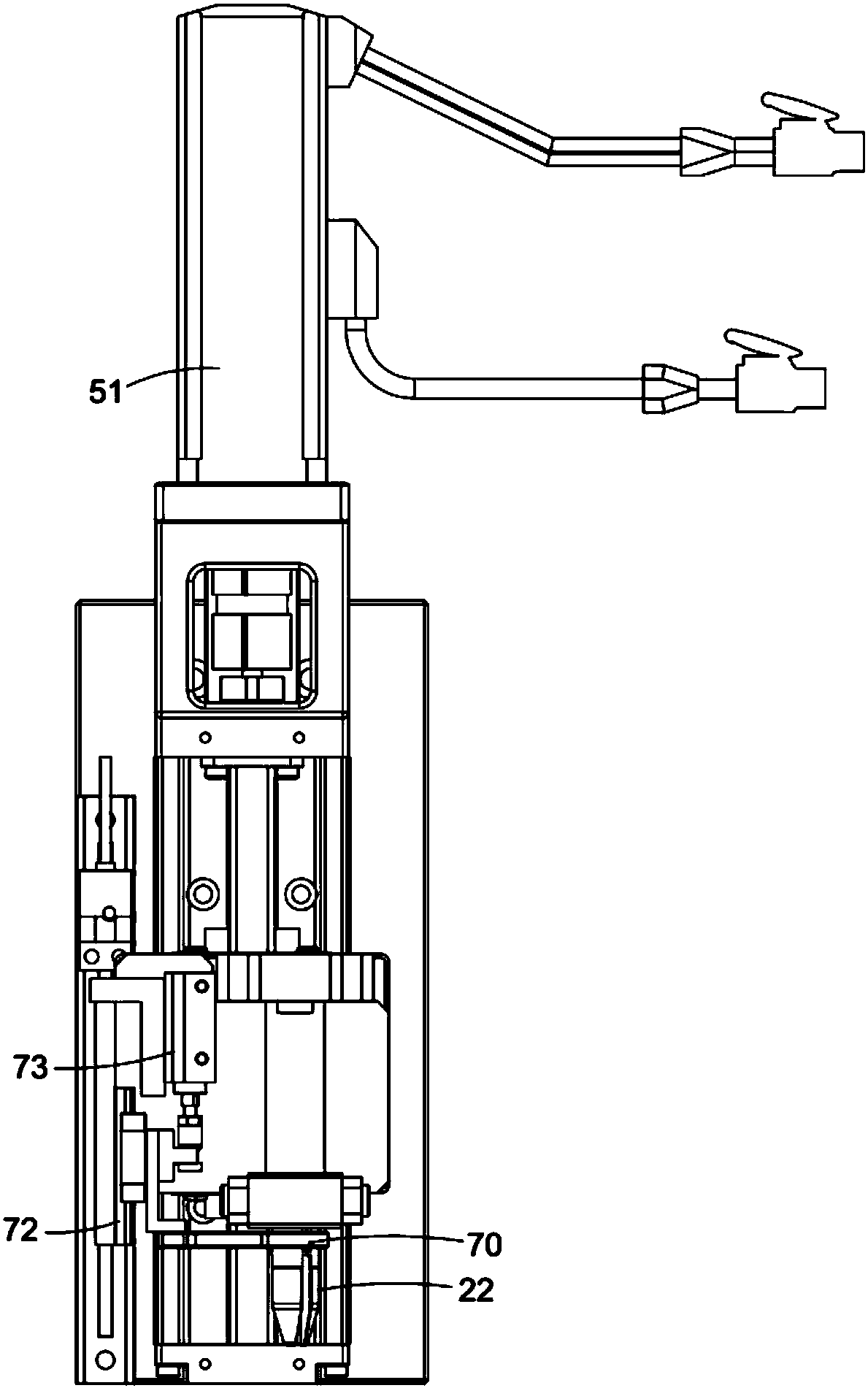

[0039] combine Figure 4 , Figure 5 The material distribution mechanism 40 includes a material distribution cylinder 41 and a material distribution fork 42 installed on the material distribution cylinder. The material distribution fork is provided with a semicircular gap 420 for receiving the sealing ring on the upper material flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com