Roller-adjustable molding press

A technology of molding presses and rollers, which is applied in the fields of printing machines and molding presses, and can solve problems such as incompatibility of molding presses, connection errors, and many assembly parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further illustrate the features and advantages of this patent, further description will be given below in conjunction with the accompanying drawings:

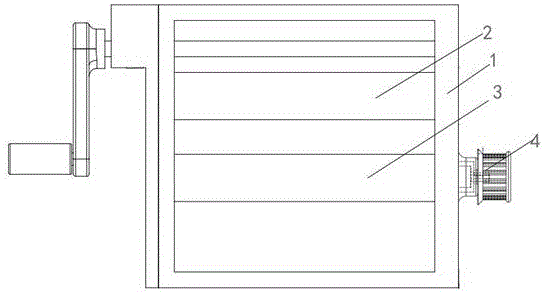

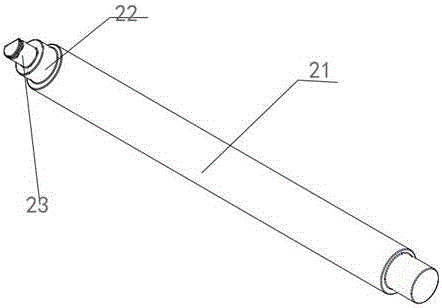

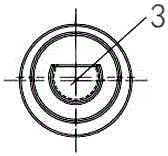

[0014] As shown in the figure, a molding machine with adjustable rollers includes a frame 1, rollers 2 and 3 added on the frame, a transmission mechanism, the gear of the transmission mechanism and the upper roller The gears are connected; the two gears are meshed to drive the upper roller to run, and the upper roller drives the lower roller to rotate relatively; the two ends of the roller are fixedly connected to the frame through bearings, and the lower roller can be The adjustable wheel roller, the adjustable wheel roller 3 is composed of an outer roller 21, an adjustment wheel core 23 and a bearing 22; the outer roller is sleeved outside the bearing, and the adjustment wheel core passes through the bearing center; the adjustment wheel Both ends of the core are connected to the frame, and an adjustment kno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com