Film sticking device for mouse case

A film sticking device and casing technology, which is applied in packaging and other directions, can solve the problems of difficulty in guaranteeing the quality of film sticking and slow efficiency of manual film sticking, and achieve the effects of improving processing efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

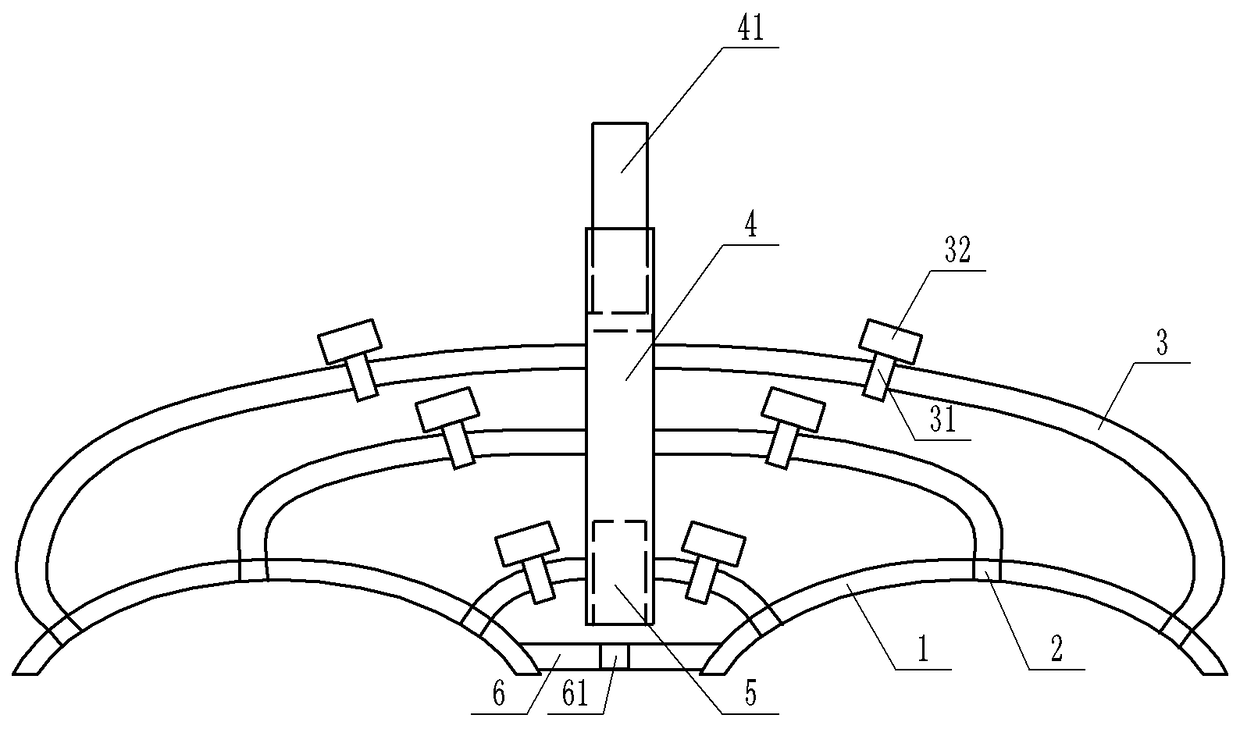

[0014] The reference signs in the drawings of the description include: mold 1, vent hole 2, vent pipe 3, solenoid valve 31, solenoid valve controller 32, gas storage pipe 4, piston 41, air extraction device 5, fixed plate 6, clamping part 61.

[0015] Such as figure 1 As shown, the film sticking device for the mouse shell includes an air storage pipe 4, the upper end of the air storage pipe 4 is provided with a piston 41, and the piston 41 can slide up and down along the air storage pipe 4 under the action of external force; Air extraction device 5. The right side of the gas storage pipe 4 is the first film-attached part, and the left side is the second film-attached part, and the structures of the first film-attached part and the second film-attached part are exactly the same. A fixing plate 6 is connected between the mold of the first film sticking part and the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com