Paper box plate vacuum packaging laminating machine with high safety

A technology of vacuum packaging and carton board, applied in the direction of coating, etc., can solve the problems of inaccurate coating, affecting the quality of carton board coating, bubbles, etc., achieve high safety, improve the uniformity and firmness of attachment sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

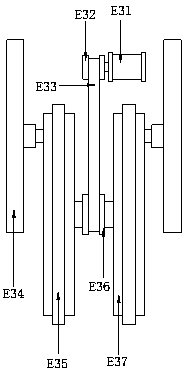

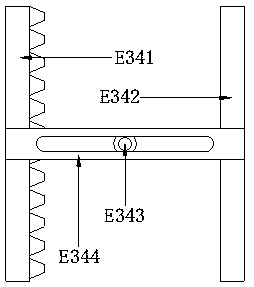

[0036] see Figure 1-5, the present invention provides a high-safety carton board vacuum packaging laminating machine technical solution: its structure includes a laminating device 1, a translation device 2, an adsorption table 3, a body 4, a carton board 5, and a supporting foot 6, The inner wall of the body 4 is provided with a translation device 2, the translation device 2 is equipped with a film coating device 1, and the film coating device 1 is located directly above the adsorption table 3, and a carton board 5 is placed on the adsorption table 3, The adsorption table 3 is fixed on the body 4, and the bottom of the body 4 is vertically connected with a supporting foot 6;

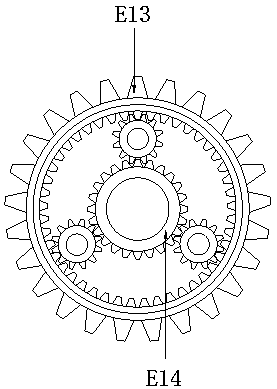

[0037] The laminating device 1 includes a pressing mechanism 11, a housing 12, a film shaft 13, a film cylinder 14, a first guide roller 15, a second guide roller 16, a rubber roller 17, and a pressing roller 18. The housing 12 A film shaft 13 is fixed inside, and a film tube 14 is placed on the film s...

Embodiment 2

[0044] see Figure 1-10 , the present invention provides a high-safety carton board vacuum packaging laminating machine technical solution: its structure includes a laminating device 1, a translation device 2, an adsorption table 3, a body 4, a carton board 5, and a supporting foot 6, The inner wall of the body 4 is provided with a translation device 2, the translation device 2 is equipped with a film coating device 1, and the film coating device 1 is located directly above the adsorption table 3, and a carton board 5 is placed on the adsorption table 3, The adsorption table 3 is fixed on the body 4, and the bottom of the body 4 is vertically connected with a supporting foot 6;

[0045] The laminating device 1 includes a pressing mechanism 11, a housing 12, a film shaft 13, a film cylinder 14, a first guide roller 15, a second guide roller 16, a rubber roller 17, and a pressing roller 18. The housing 12 A film shaft 13 is fixed inside, and a film tube 14 is placed on the film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com