Method for pouring protective layer for printed matter and object manufactured by using method

A technology of protective layer and printed matter, applied in the direction of printed matter, printing post-processing, printing, etc., can solve the problems of corrosion reaction, pattern layer damage, glue opening, etc., and achieve foreign object impact resistance, long coating life and good coating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

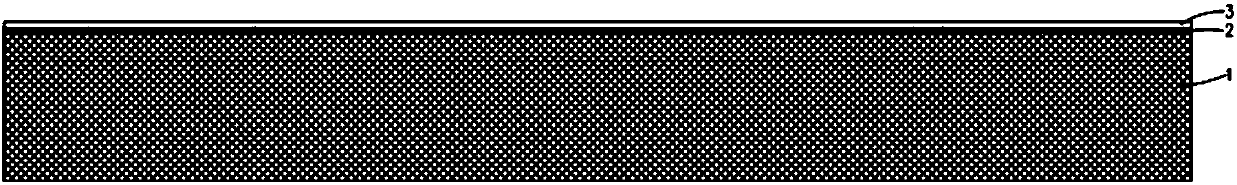

[0016] refer to figure 1 As shown, the present invention employs an embodiment of an article made by casting a protective layer to a printed matter. It includes an article model 1 and a pattern layer 2 printed on the surface of the article model. The pattern layer 2 uses polyurethane ink, and a transparent protective layer 3 is poured on the pattern layer 2 on the surface of the article model. The protective layer 3 uses liquid The CPU-type polyurethane is solidified and solidified on the surface of the pattern layer 2. In fact, there is a cross-linking reaction between molecules between the pattern layer 2 and the protective layer 3, and the combination is firm. Therefore, the transparent protective layer and the pattern layer are solidified and combined, the film is firm, the effect of the film is good, and it can form protection in many wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com