Automatic packaging machine

An automatic packaging machine and packaging bag technology, applied in packaging machines, packaging, transport packaging and other directions, can solve the problems of low automation of packaging machines, different cutting lengths of packaging bags, and low quality of packaging bags, and save work. Time, simple structure, anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]The present invention will be further described in detail below in conjunction with the accompanying drawings, and the aforementioned and other objects, features, aspects and advantages of the present invention will become more apparent, so that those skilled in the art can implement them with reference to the description.

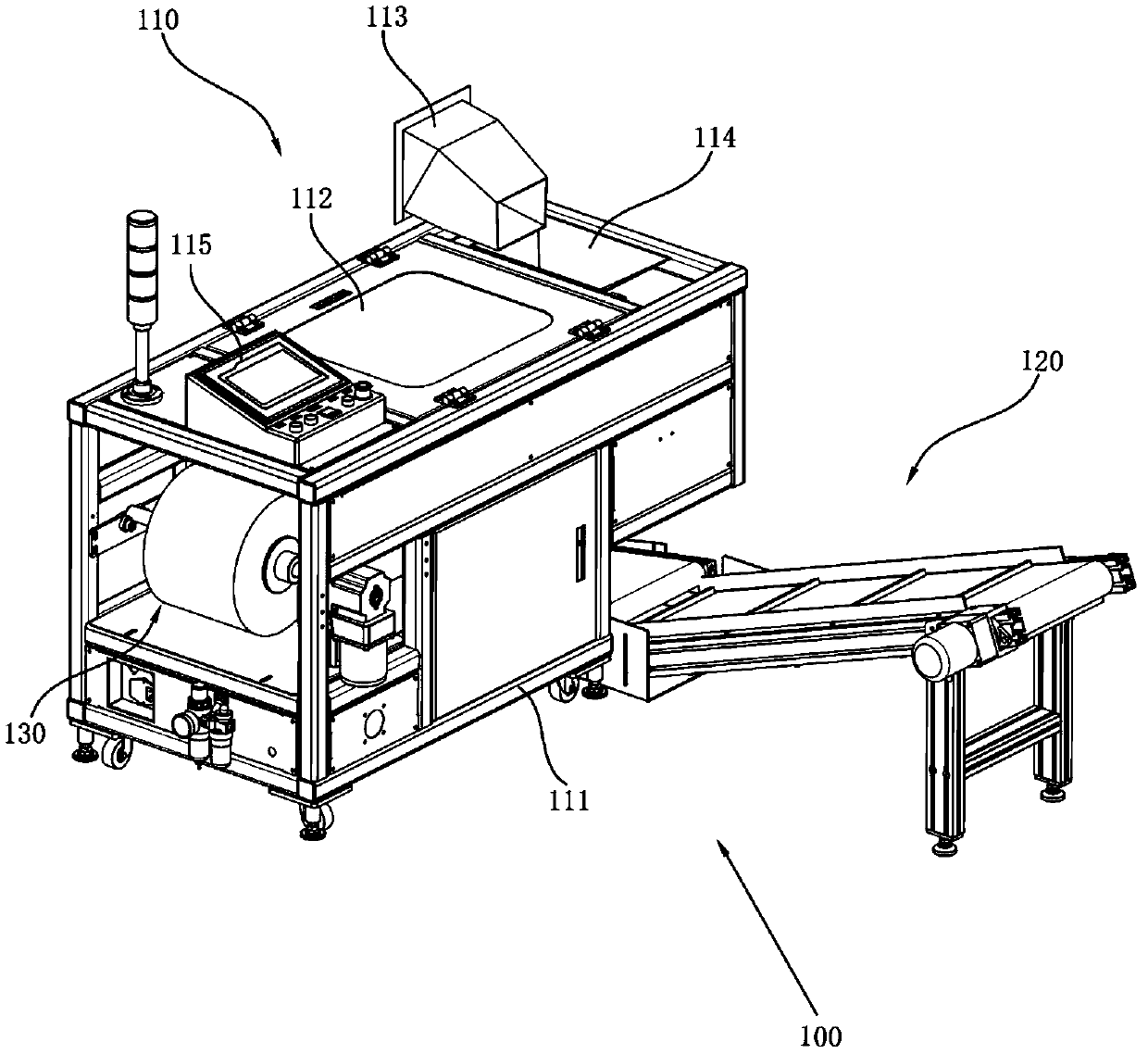

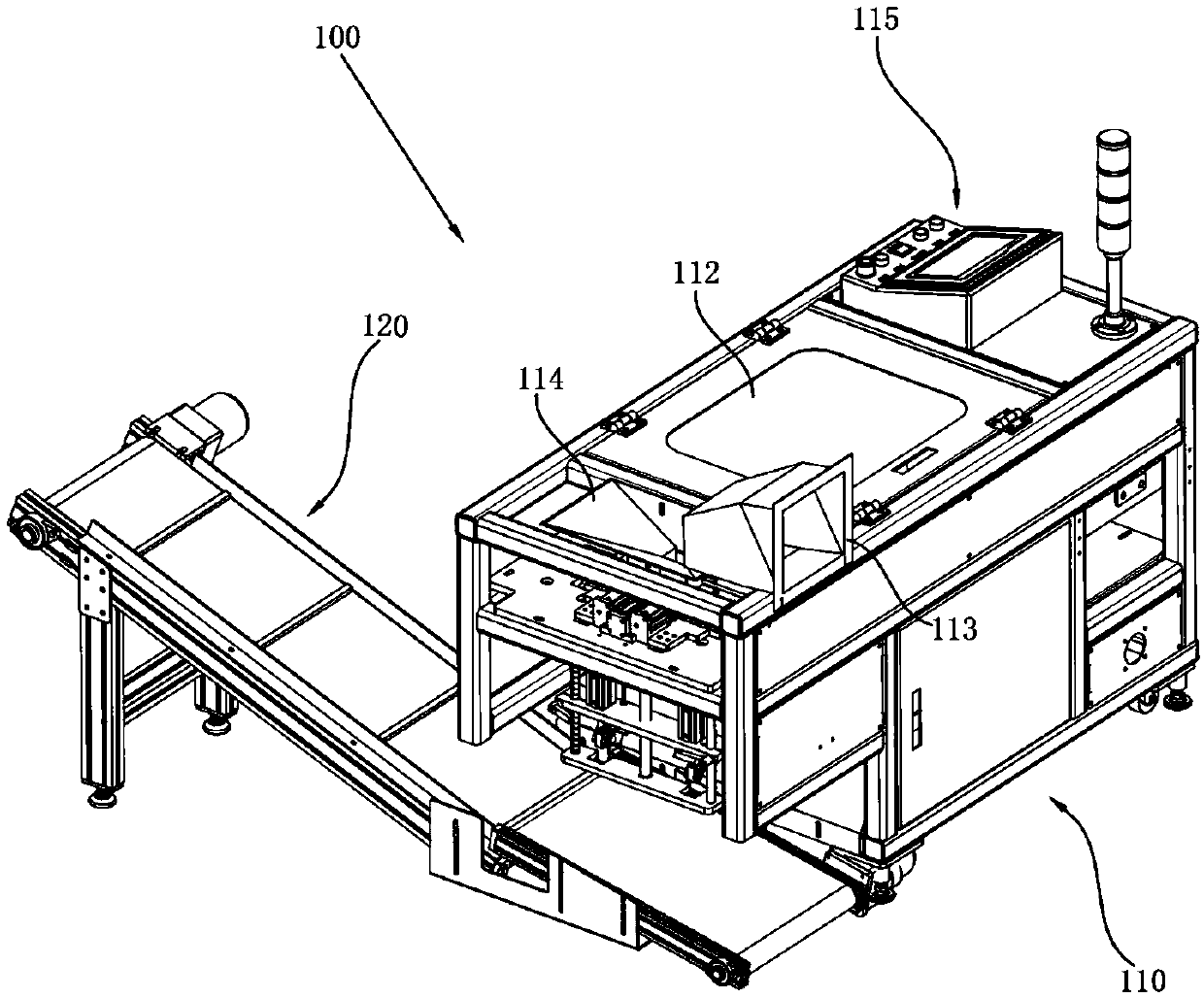

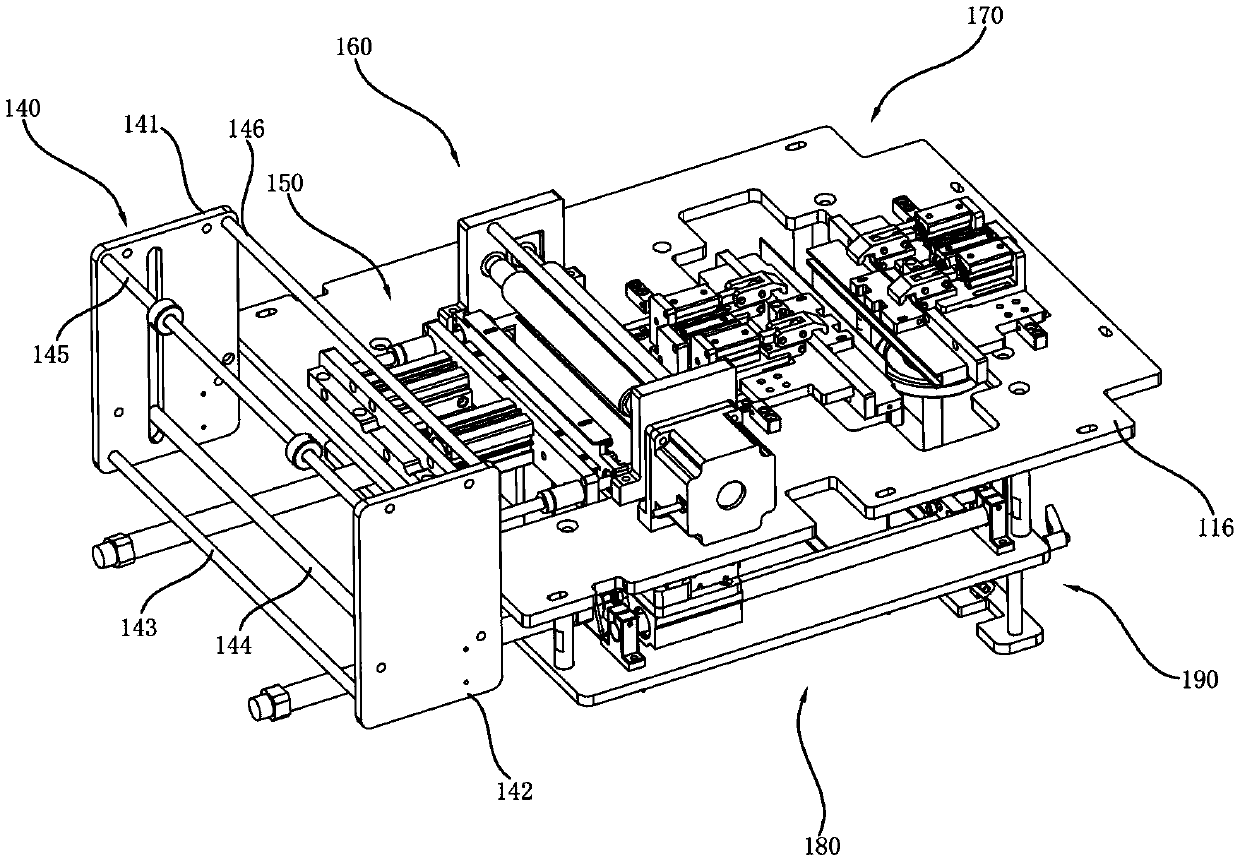

[0063] refer to Figure 1 to Figure 5 , the automatic packaging machine 100 includes: a control system (sketched), a frame 110, a conveyor belt 120, a feeding mechanism 130, a feeding control mechanism 140, a back cover cutting mechanism 150, a transmission mechanism 160, a charging and sealing mechanism 170, and a bag feeding mechanism 180 , and a carrying mechanism 190, wherein, the frame 110 has a certain internal space, the feeding mechanism 130, the feeding control mechanism 140, the conveying mechanism 160, the back cover cutting mechanism 150, and the bag feeding mechanism 180 are sequentially arranged along the conveying direction of the packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com