Automatic line cutting machine and process

A wire cutting machine and automatic technology, applied in metal processing equipment and other directions, can solve the problems of low production efficiency, low wire cutting accuracy, and different fiber wire lengths, and achieve precise wire cutting length, high production efficiency, and guaranteed quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

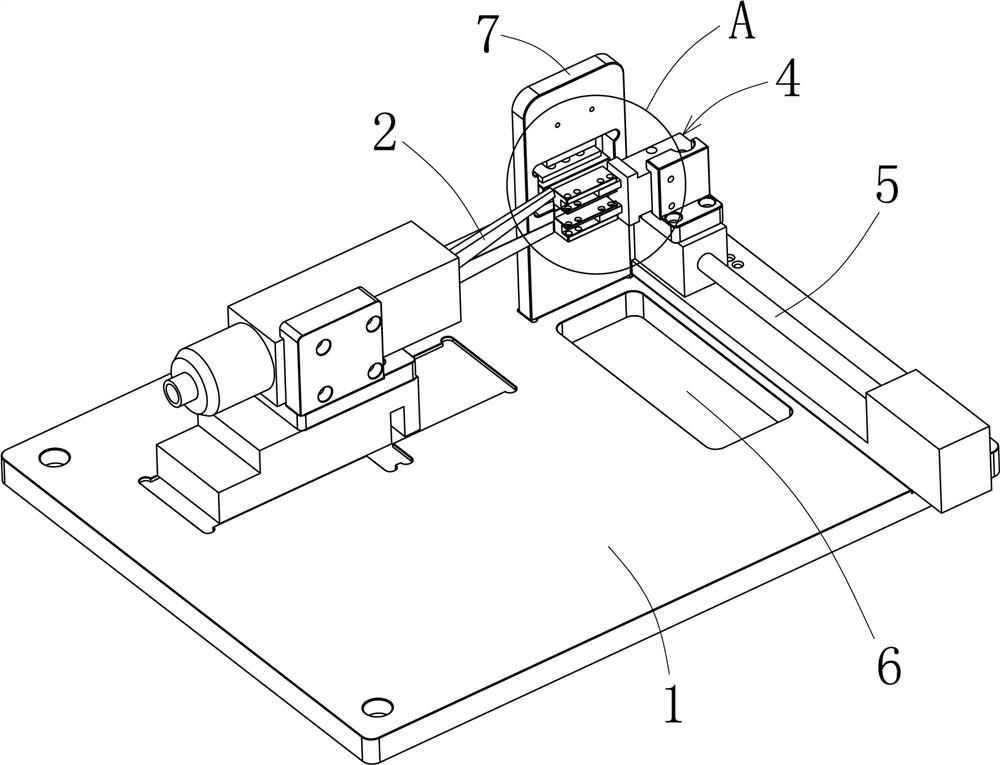

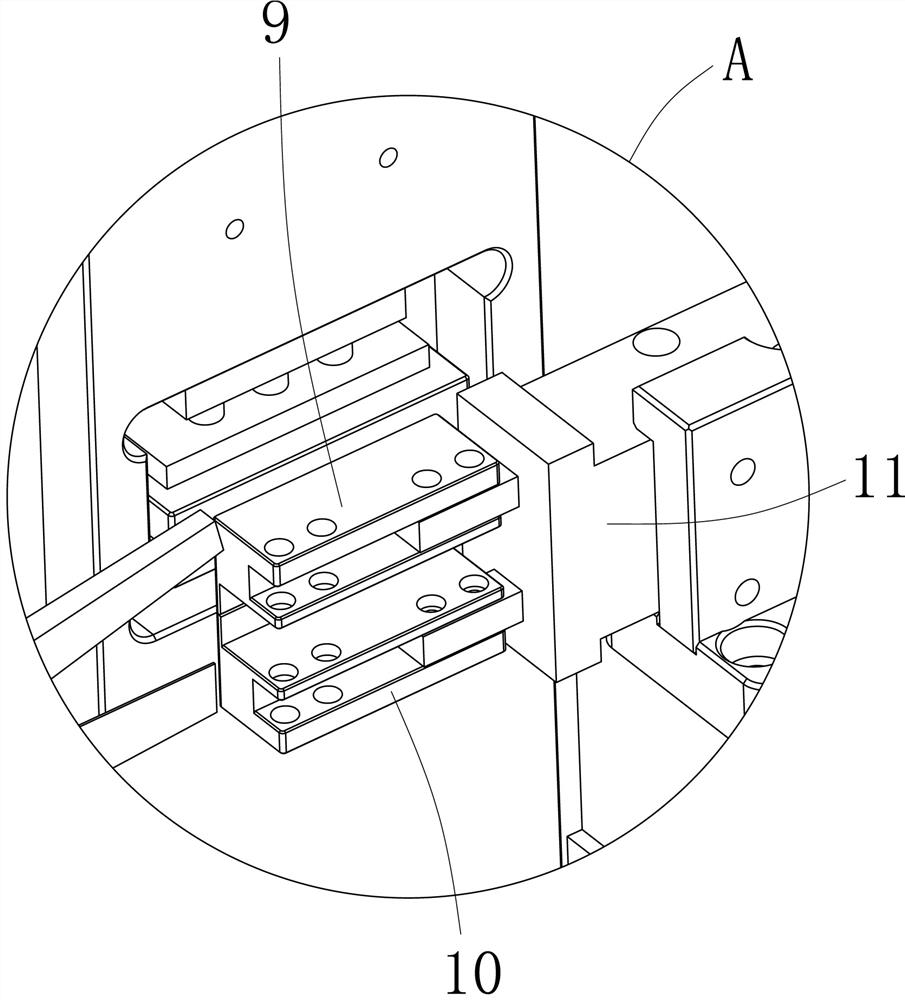

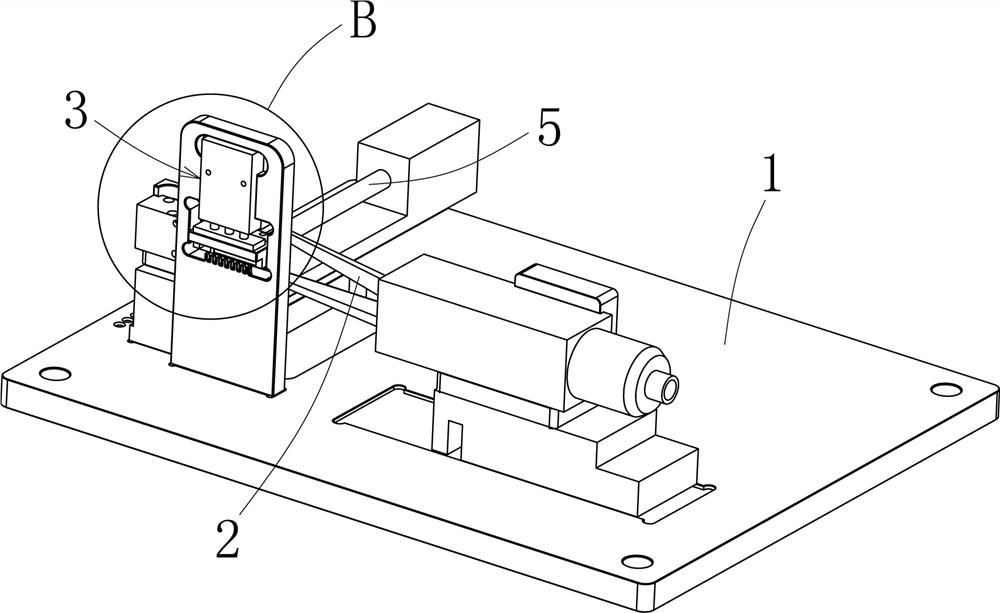

[0039] Please refer to Figure 1-7 , the embodiment of the present invention includes:

[0040] An automatic wire cutting machine for cutting fiber wires, including a worktable 1, a cutting knife 2, a positioning clip 3, a feeding clip 4, and a fixed-length motor 5, and a discharge port 6 is dug on the worktable 1, and the discharge port There is a receiving box below 6, a vertical plate 7 is set on the workbench 1, and the vertical plate 7 is located at the edge of the discharge port 6, and a window 8 is dug on the vertical plate 7, and the positioning clamp 3 is used to clamp the Fiber line and position The clamp 3 is located at the window 8, and the feeding clamp 4 is used to clamp and pull the Fiber line. The feeding clamp 4 is located above the outlet 6 and next t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com