Nonmetal rotating shaft convenient to power

A non-metallic and rotating shaft technology, applied in the field of nanofiber preparation, can solve the problems of affecting the electric field of the spinning emitter, energy waste, and affecting the spinning effect, so as to avoid the problem of wire winding, simple connection method, and reduce energy waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

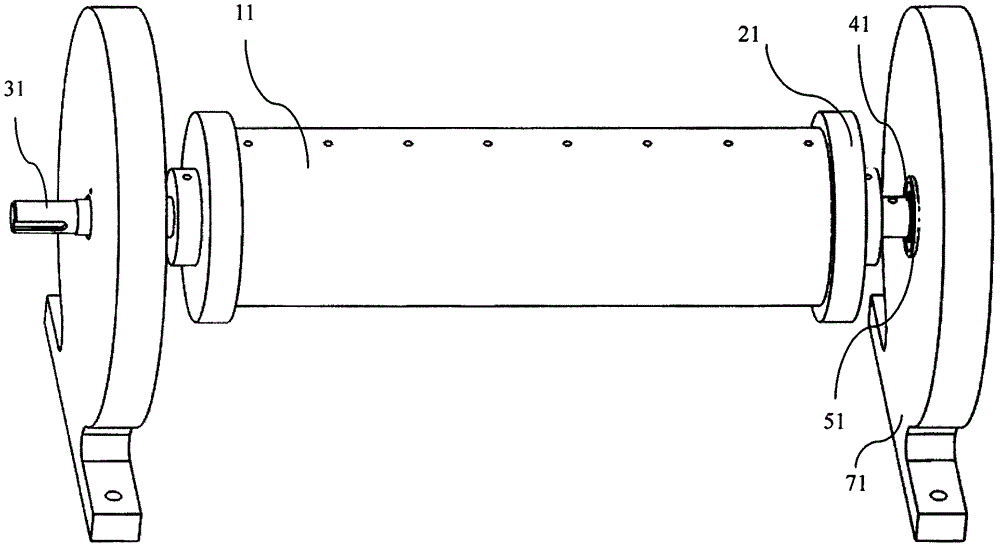

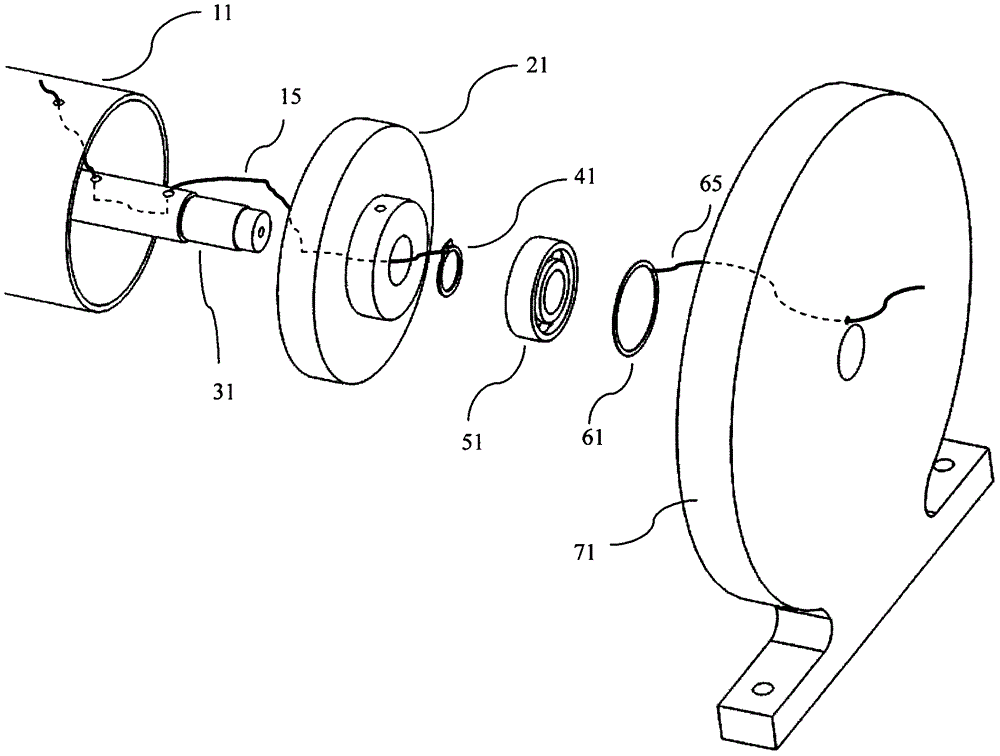

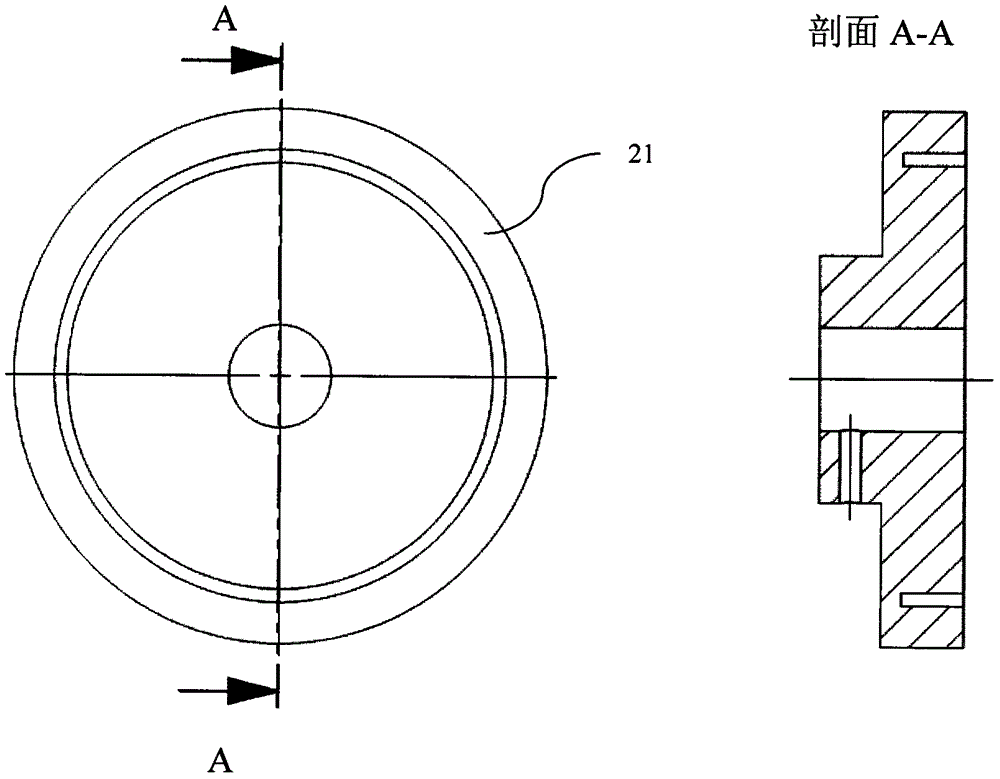

Embodiment 1

[0023] Electrospinning emits extremely discontinuous monomer structures such as Figure 4 As shown, it is specifically 8 disc-shaped electrospinning emitters 12 arranged at equal intervals, and then 8 small holes with a diameter of 3 mm are opened on the support sleeve 11 parallel to the axis, and are respectively connected with 8 circularly arranged at equal intervals. Corresponding to the disc-shaped electrospinning emitter 12, one end of the 8 metal wires is respectively connected to the disc-shaped electrospinning emitter 12, and then the 8 wires are respectively introduced into the support from the corresponding small holes on the support sleeve 11. Inside the casing 11, and twisted into a wire 15, it penetrates the central shaft 31 from the hole 1 on the central shaft 31, and is drawn out from the hole 2, and the wire 15 is tied to the circular hole of the snap ring 41; the fixed ring 61 Before installation, one end of a metal wire 65 is tied to the fixed ring 61, and th...

Embodiment 2

[0025] Electrospinning emits extremely continuous structures such as Figure 5As shown, it is specifically a helical blade type electrospinning emitter 13, and a small hole with a diameter of 3 mm is opened on the support sleeve 11 at a distance of 10 mm from the left end face of the end cover of the support sleeve at the right end, and one end of a metal wire is connected to the The spiral blade type electrospinning emitter 13 is connected, and the other end of the metal wire 15 is introduced into the support sleeve 11 from the corresponding small hole on the support sleeve 11, and penetrates the central shaft 31 from the hole 1 on the central shaft 31, Draw out from hole 2, and wire 15 is fastened in the round hole of jump ring 41; Described fixed ring 61 is before installation, and one end of a metal wire 65 is tied on the fixed ring 61, and the other end is from described bearing seat 71 bearing Pass through the small hole above the hole, and then install the fixed ring 61...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap