Compressor blade reverse implementation method for correcting multi-dimensional processing error

A technology of machining error and realization method, which is applied in the direction of using mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problem of inability to determine blade benchmarks, shorten the time for reverse design of compressor blades, and inability to reverse multi-dimensional processing errors. It can save the cost of blade measurement and data processing, shorten the design time, and improve the quality of the blade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

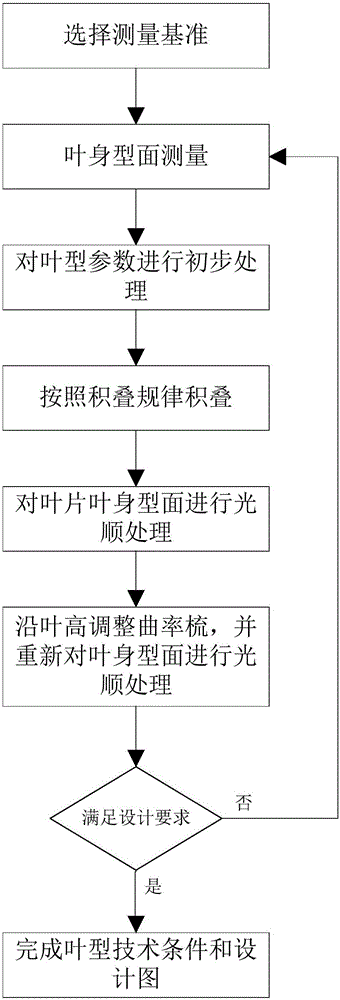

[0041] like figure 1 As shown, this embodiment includes the following steps:

[0042] 1) Select the measurement benchmark:

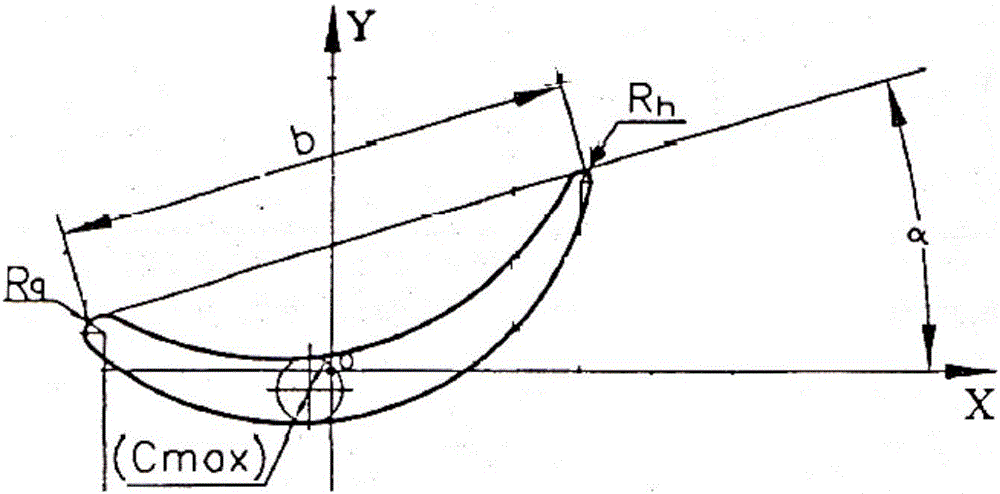

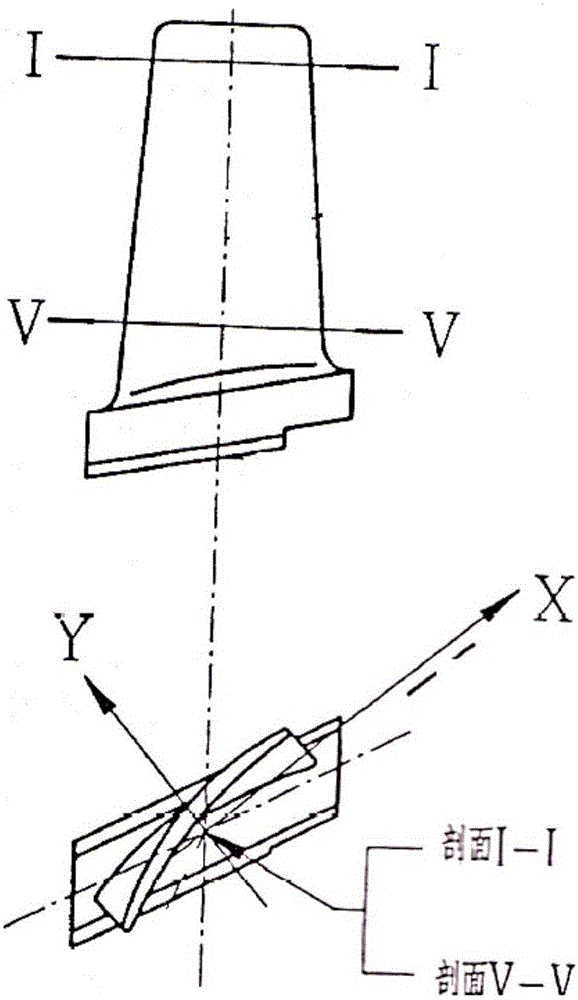

[0043] 1.1) Determining the x-axis from component condition measurements with the blades located in the compressor component. The rotor blades and stator blades of the compressor are divided into two types: detachable and non-detachable. Non-detachable blades, such as the integral blisk type of the rotor blade, and the integral welded type of the inner and outer rings of the stator blade. Whether it is a detachable blade or a non-detachable blade, the x-axis can be determined using blade assembly state measurements. The front and rear end surfaces of the blade assembly are rotating planes. First, according to the structural characteristics of the assembly, determine the center line of the assembly, that is, the axis of the compressor, and measure the roundness of the spigot as a reference. The spigot is the cylindrical surface that the assembly fits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com