Rail-type automatic evaporator leak detector

An evaporator and track-type technology, which is applied in the field of devices for detecting the air tightness of evaporator pipelines, can solve the problems of inaccurate and unscientific detection methods, achieve accurate detection results, save manpower, and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

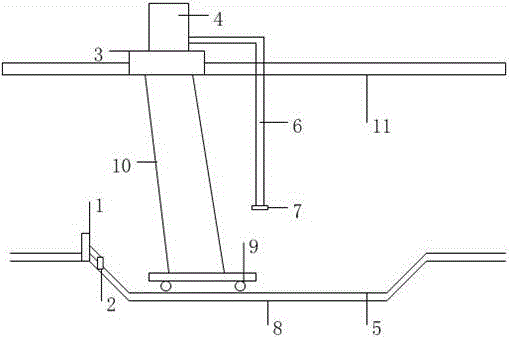

[0008] Such as figure 1 As shown, the present invention includes a top rail 11, a bottom rail 5, a traction line 10, a traction arm 3, a rail car 9, a gas booster pump 4, a leak detection pool 8, a connecting pipe 6, a plug, and the traction arm 3 is installed On the top rail 11, the traction line 10 is fixed on the traction arm 3, the two opposite sides of the leak detection pool 8 are slopes, the bottom rail 5 passes through the two slopes, the The gas booster pump 4 is fixed on the traction arm 3, one end of the connection pipe 6 is connected to the gas booster pump 4, and the other end is connected to a port of the evaporator pipeline to be tested, and the connection pipe There is a ferrule joint 7 at the end; there are scales and a liquid level switch 2 on the edge of the leak detection tank 8, and the liquid level switch 2 is connected to the PLC controller 1.

[0009] More specifically, the traction arm 3 has a platform for carrying the gas booster pump 4 and bolts and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com