Steel bar and concrete performance testing device and method

A technology of concrete and steel bars, applied in measuring devices, using mechanical devices, and applying stable tension/pressure to test material strength, etc. To achieve the effect of preventing the eccentric damage of steel bars, eliminating the phenomenon of unloading, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

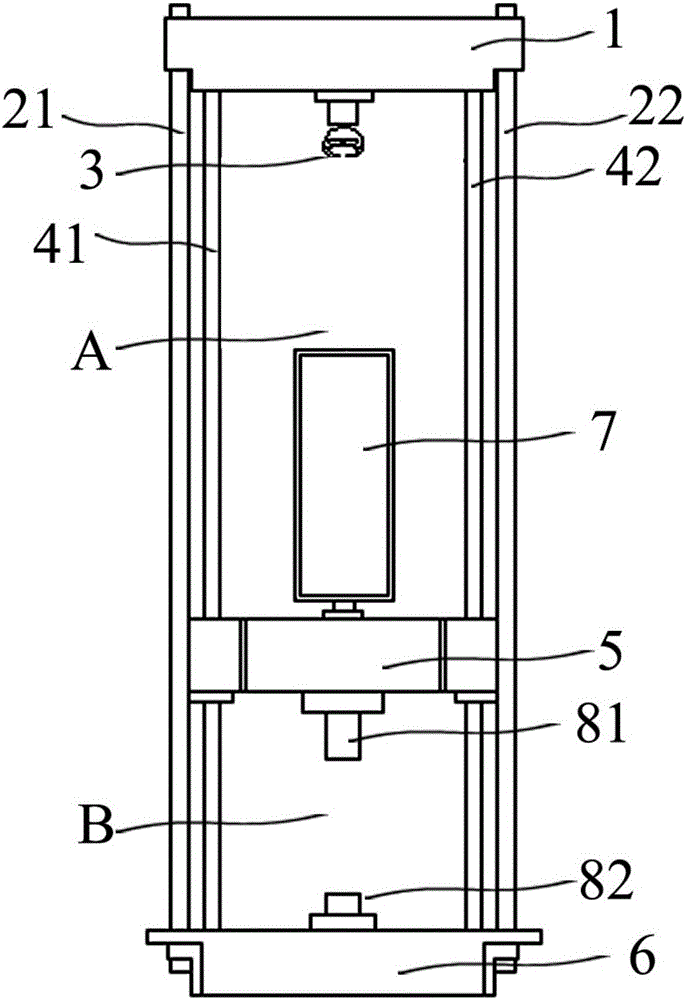

[0036] figure 1 It is a schematic diagram of the overall structure of a steel bar and concrete performance testing device of the present invention. Such as figure 1 As shown, the device of the present invention includes an upper beam 1, a first support rod 21, a second support rod 22, a claw 3, a first lead screw 41, a second lead screw 42, a loading frame 5, and a base 6, wherein the upper The beam 1, the first support rod 21, the second support rod 22 and the base 6 are detachably connected into a frame shape, the claw 3 is detachably connected on the upper beam 1, and the first lead screw 41 and the second lead screw 42 are connected via The bearing (not shown) is connected with the upper beam 1 and the base 6 and is driven to rotate by a motor (not shown). The loading frame 5 is detachably set on the first lead screw 41 and the second lead screw 42. When the bar 41 and the second leading screw 42 rotate, the loading frame 5 moves up and down to complete the loading. The...

Embodiment 2

[0045] Except that the first lead screw 41 and the second lead screw 42 in embodiment 1 are replaced by ball screws with screw rods, other components and parameters are the same as in embodiment 1.

Embodiment 3

[0047] Except that the bearing in embodiment 1 is replaced by an axial thrust bearing by a radial bearing, other components and parameters are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com