Two-segment type insulation porcelain injection fuse of fuse tube peripheral equipment insulating layer

A technology of fuse tube and insulating porcelain, which is applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve the problems of incomplete breaking, easy generation of arc, and inability to determine the fuse, so as to avoid discharge phenomenon and pop up reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

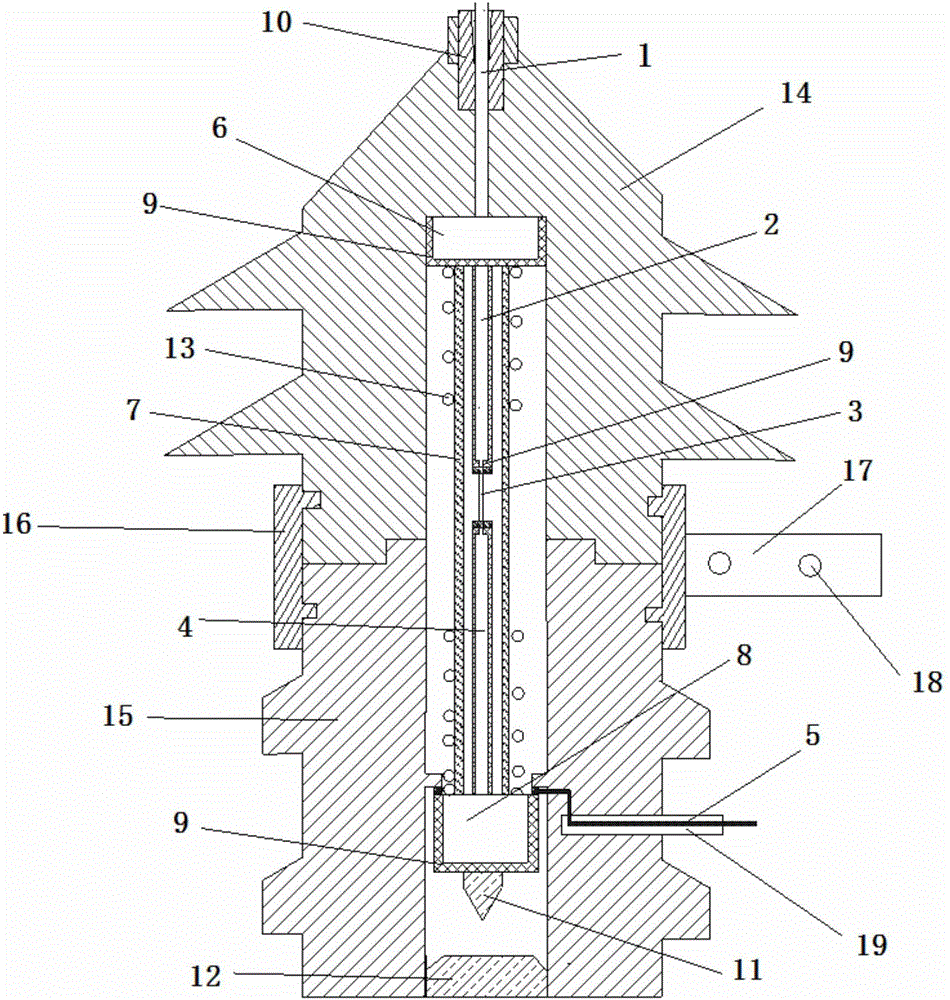

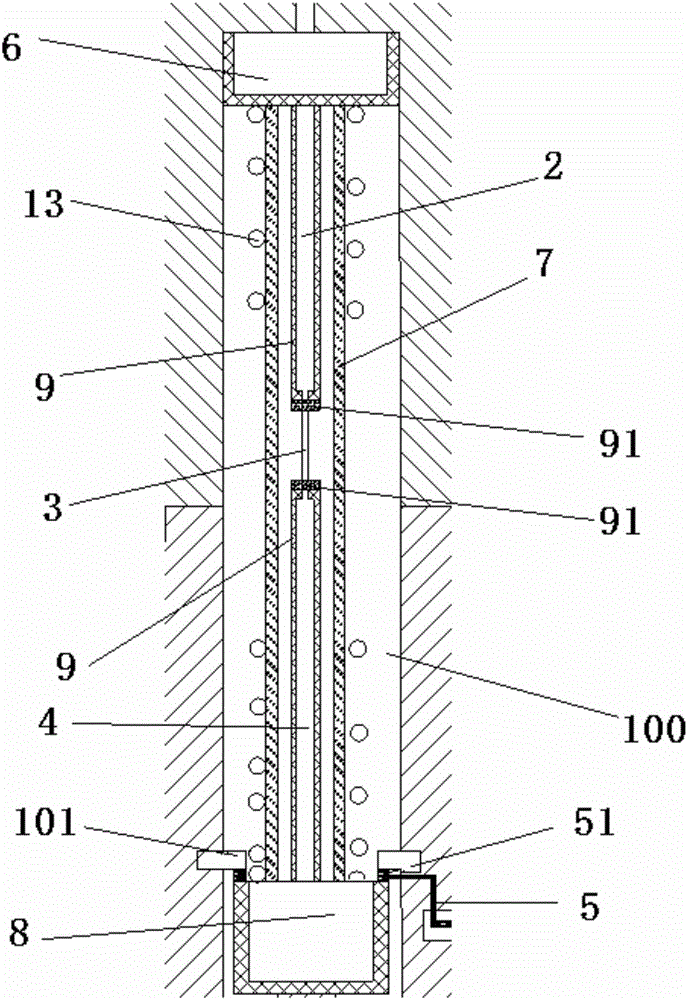

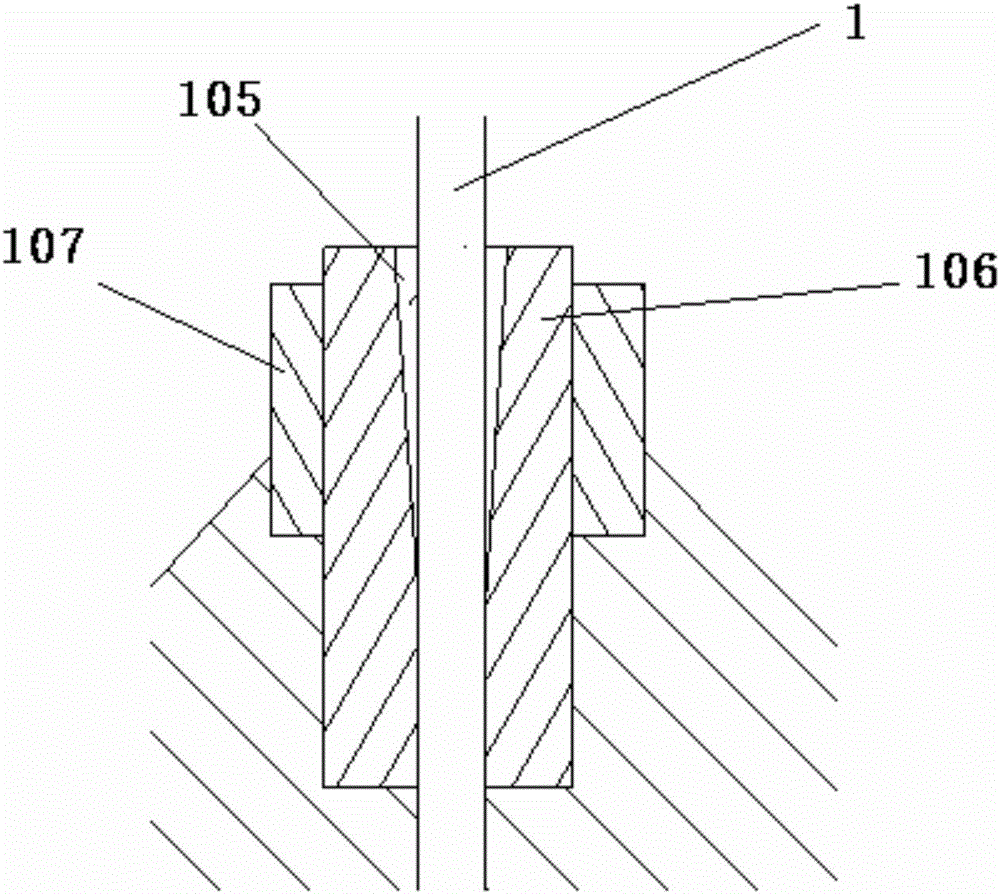

[0010] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, the present invention includes an insulating porcelain body and a fuse tube arranged in the axial cavity 100 of the insulating porcelain body. The insulating porcelain body includes two parts: an upper insulating porcelain body 14 and a lower insulating porcelain body 15. The insulating porcelain body The top of the porcelain body is provided with a locking device 10; as image 3 As shown, the locking device 10 includes a jacket 106 fixed in the groove on the top of the insulating porcelain body, the outside of the jacket 106 is provided with threads, and a wedge-shaped through hole 105 is arranged in the middle; the lead-out line 1 of the upper fuse tube 6 Through the wedge-shaped through hole 105; the clamping nut 107 is arranged outside the jacket 106, and the inner diameter of the clamping nut 107 is smaller than the outer diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com