Integrated VFTO measuring bus and bus cylinder thereof

An integrated technology of bus barrel, which is applied in the field of integrated VFTO measurement bus and its bus barrel, can solve the problems of cumbersome measurement and achieve the effect of reducing construction operations, stable and reliable support, and convenient repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

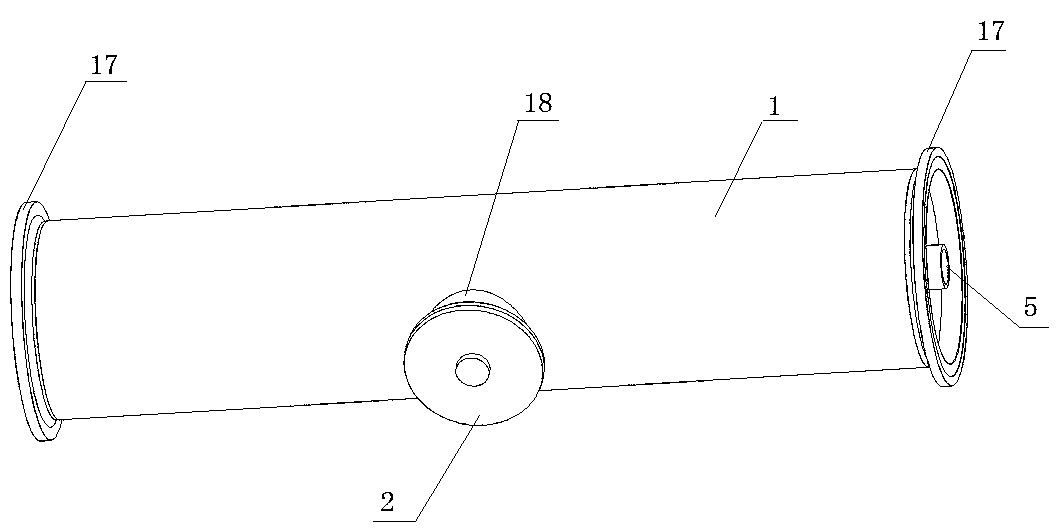

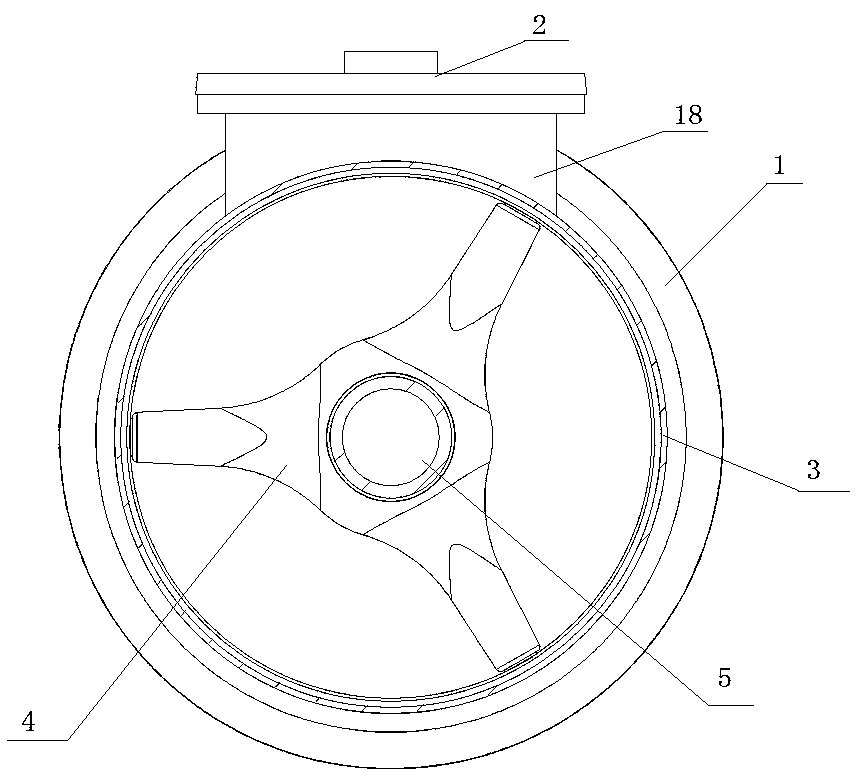

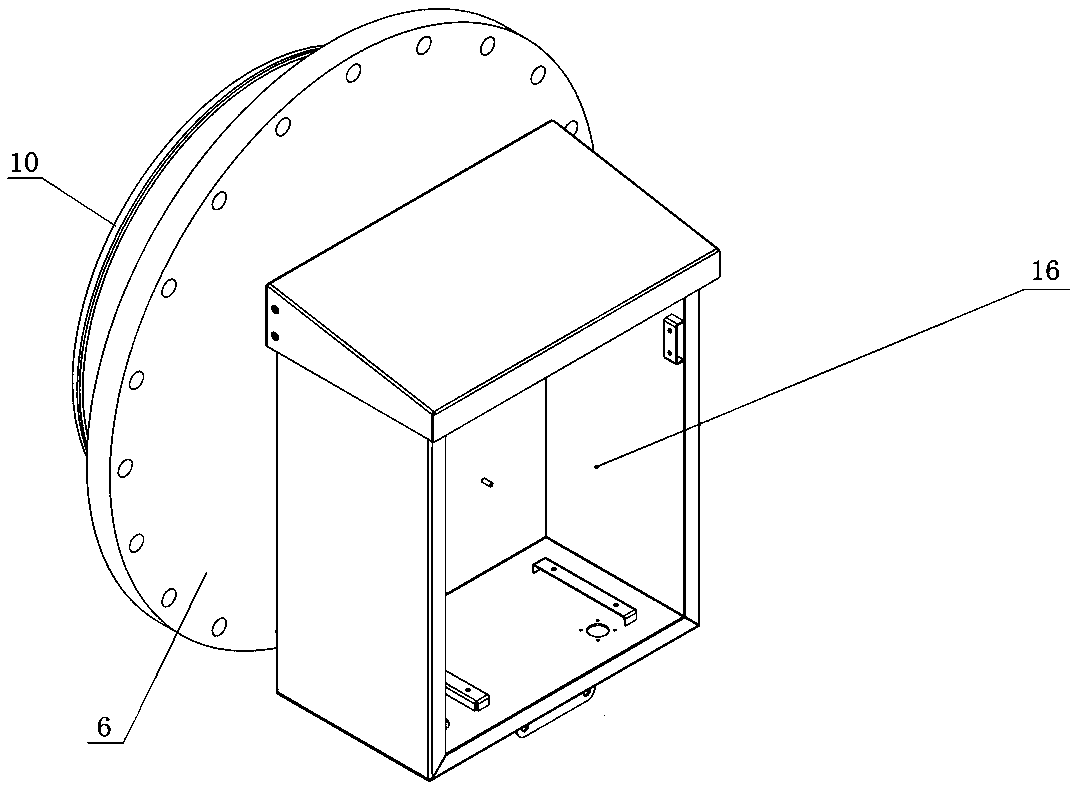

[0073] like figure 1 figure 2 , image 3 and Figure 4 As shown, the integrated VFTO measuring bus includes a bus barrel 1 and a VFTO measuring device 2 integrated on the bus barrel 1. The two ends of the bus barrel 1 are respectively provided with barrel flanges 17, so as to correspond to the corresponding GIS / GIL bus connection. The busbar barrel 1 is provided with a three-pillar insulator 4 , and the three pillars of the three-pillar insulator 4 are respectively in contact with the barrel wall of the busbar barrel 1 for fixing the conductive rod 5 penetrated in the busbar barrel 1 . A cylindrical particle trap 3 is also provided in the busbar barrel 1 . The side of the busbar barrel 1 is provided with a pull-out port, and the pull-out port is fixedly fitted with a flange matching barrel 18 extending along the radial direction of the busbar barrel 1. The VFTO measuring device 2 is connected to the flange matching barrel 18 through the connecting flange 6 on it. The in...

Embodiment 2

[0082] The difference between this embodiment and the above-mentioned Embodiment 1 is that in this embodiment, a sealing sleeve is set on the outside of the entire VFTO measuring device, and the sensor is located in the sealing sleeve. To realize the integration of VFTO measuring device and busbar barrel.

Embodiment 3

[0084] The difference between this embodiment and the above-mentioned Embodiment 1 is that in this embodiment, no support seat and transition flange are provided, and the shielding ring is directly connected to the connecting flange through bolts and nuts, but it must be ensured that the shielding ring is connected to the conductive rod and the bus bar. The distance between the cylinders meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com