Novel brown rice germ humidifying device

A brown rice germ and humidifying device technology, applied in application, grain processing, grain milling, etc., can solve the problems that brown rice germ is not easy to remove, affects the quality of rice, and brown rice is prone to mildew. The effect of easy equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

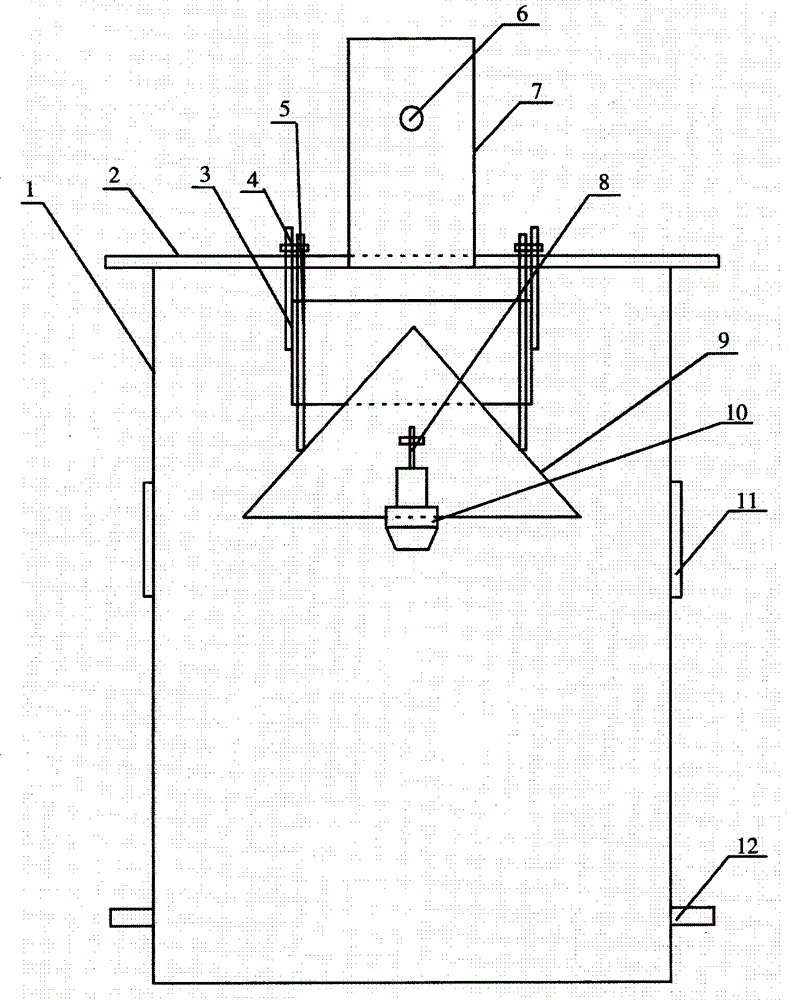

[0009] A new type of brown rice germ humidification device consists of a body 1, an upper cover plate 2, a control plate 3, a short adjustment screw 4, a long adjustment screw 5, a material level indicator 6, a joint 7, a fixing bolt 8, and a conical cap 9. The atomization motor 10, the observation window 11, the limit plate 12, etc. The body 1 is welded into a cylindrical shape by steel plates, the upper cover plate 2 is welded to the upper end of the body 1 by steel plates, and the volume control plate 3 is made of steel plates. Bolts are connected to the upper end of the body 1, the short adjustment screw 4 is made of circular steel bars, one end is welded to the two ends of the control plate 3, and the joint 7 is welded into a cylindrical shape by a thin steel plate and connected to the upper cover by bolts In the middle of the plate 2, the material level gauge 6 is connected to the middle of the upper end of the joint 8 by bolts. The conical cap 9 is welded into a conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com