Method for fixing chilling block on die slope

A technology of cold iron and inclined plane, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., and can solve problems such as difficulty in mold removal, unfavorable post-production, magnetization of metal mold cold iron, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

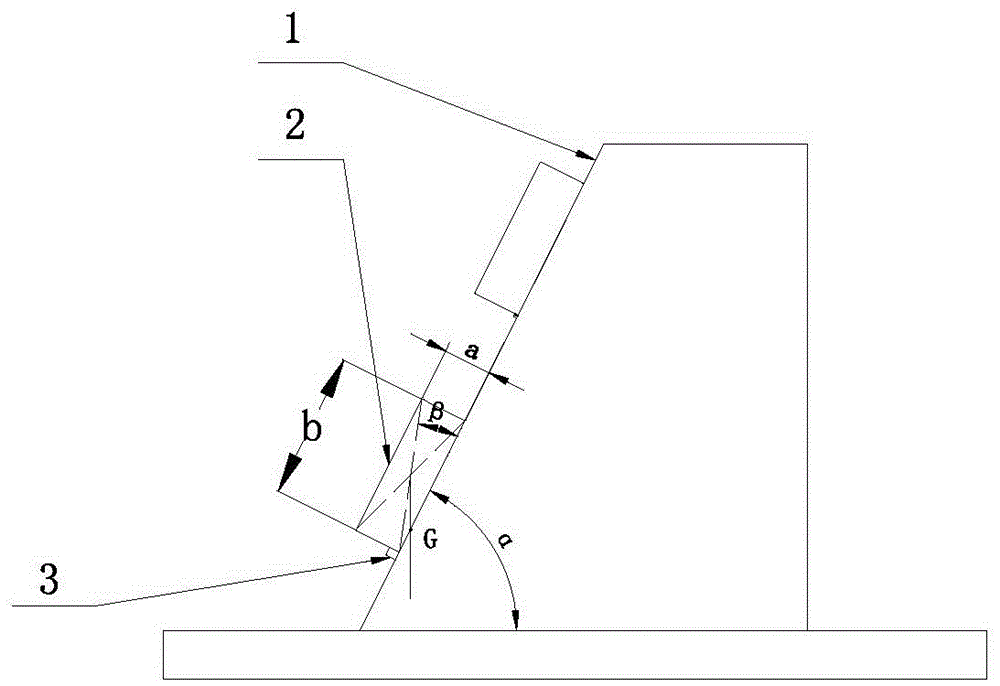

[0020] Such as figure 1 As shown, (A) First, according to the structural requirements of the casting, it is necessary to set the chill iron 2 on the mold slope 1, and according to the wall thickness of the casting tool on the slope and the size of the hot joint, determine the thickness of the chill iron to be placed on the slope as a, Among them, the value of a is 0.6-0.8 times of the size of the hot section of the casting. (B) Then measure the angle α between the above-mentioned mold slope 1 and the horizontal direction, and determine the minimum length of the length b of the cold iron according to the formulas (1), (2) and (3):

[0021] Formula 1),

[0022] Formula (2),

[0023] Formula (3);

[0024] Adopt above-mentioned method, the minimum length dimension of the cold iron of design can make the center of gravity line of cold iron 2 and the intersecting point of the mold slope 1 of placing fall in the surface that the bottom surface of cold iron overlaps with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com