A decanting device for a constant water level sequential batch process system

A process system and batch-sequencing technology, applied in the field of decanting, can solve problems such as mud run-off and drainage quality exceeding the standard, and achieve the effect of avoiding mud run-off and improving drainage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

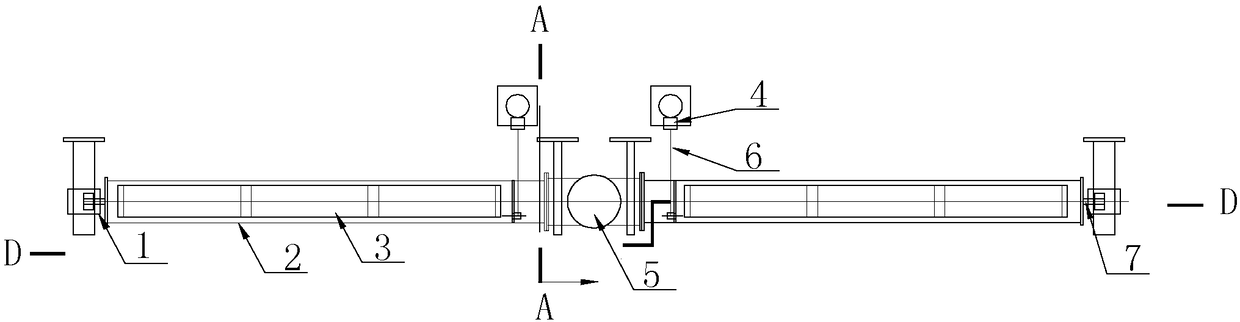

[0025] Specific embodiment 2. This embodiment is a further description of the decanting device of a constant water level sequence batch process system described in specific embodiment 1. The two horizontal ports and the lower side ports of the four-way pipe 5 are equipped with Lan, the two water-collecting horizontal pipes 2 are connected to the four-way pipe 5 through sealed packing, and the two water-collecting horizontal pipes 2 are rotatable in the four-way pipe 5, and the water-collecting vertical pipes 8 are connected to the four-way pipe through flanges. 5 connections.

specific Embodiment approach 3

[0026] Specific embodiment 3. This embodiment is a further description of the decanting device of a constant water level sequence batch process system described in specific embodiment 1 or 2. The closed ends of the two water-collecting horizontal pipes 2 are connected with support shafts , the support shaft is connected with the pool wall bearing of the sewage pool; and the support shaft is concentrically connected with the water collecting horizontal pipe 2 .

[0027] The screw drives the water-collecting horizontal pipe to rotate, and drives the supporting shaft to rotate, and the supporting shaft plays a role of supporting and fixing the water-collecting horizontal pipe, reducing the force on the water-collecting vertical pipe.

specific Embodiment approach 4

[0028] Embodiment 4. This embodiment is a further description of the decanting device of a constant water level sequence batch process system described in Embodiment 1. There are three rectangular collectors on the pipe wall of each water collecting horizontal pipe 2. The edge of each water collection port is welded with a metal plate perpendicular to the pipe wall, and the metal plate forms a water collection tank 3 along the water collection port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com