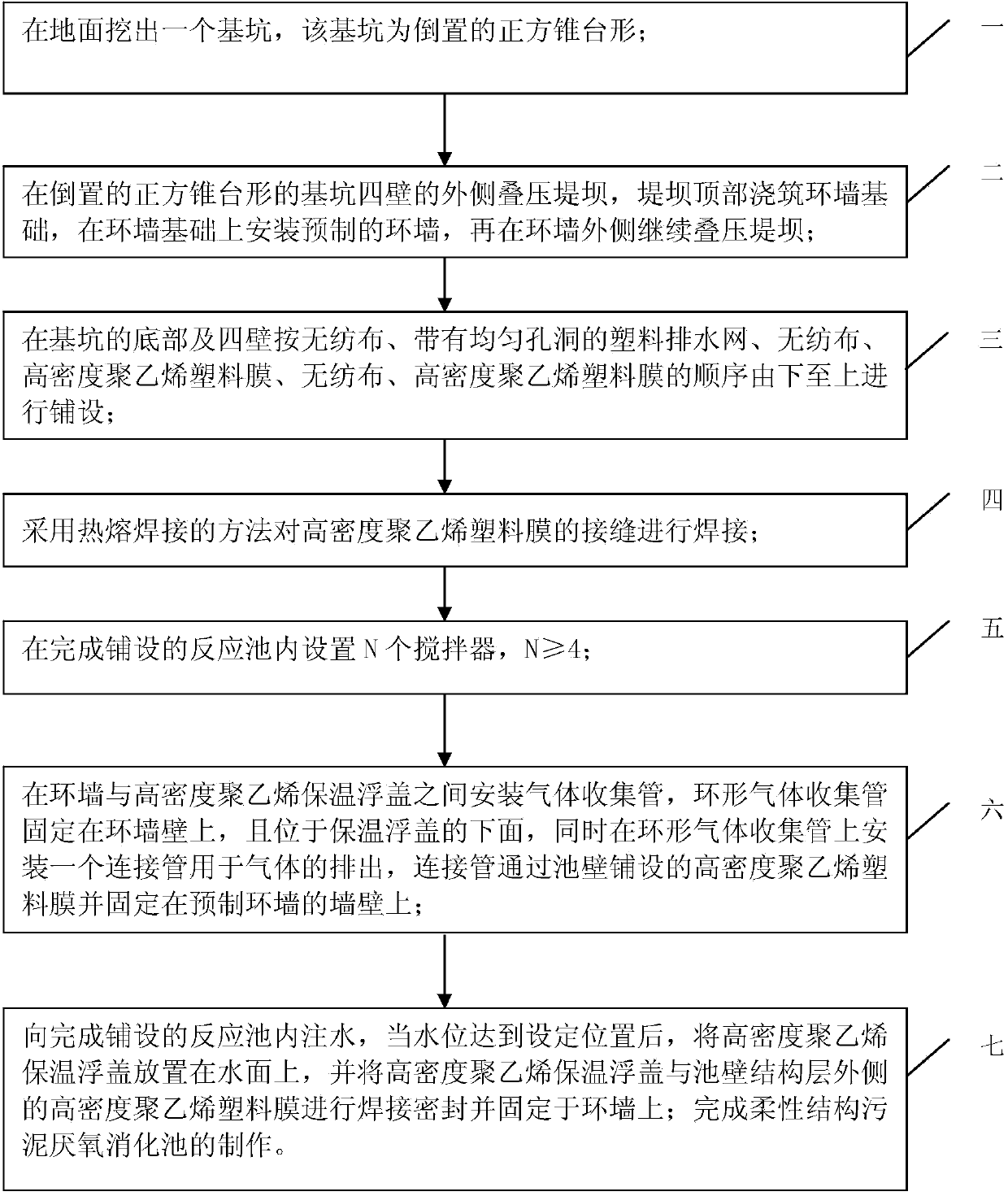

Manufacturing method of sludge anaerobic digestion reaction tank, and sludge anaerobic digestion reaction tank obtained by utilizing method

A technology of anaerobic digestion and production method, applied in biological sludge treatment and other directions, can solve the problems of difficult sealing and long construction period, and achieve the effects of improving sealing, shortening construction period and avoiding the phenomenon of running mud.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 3

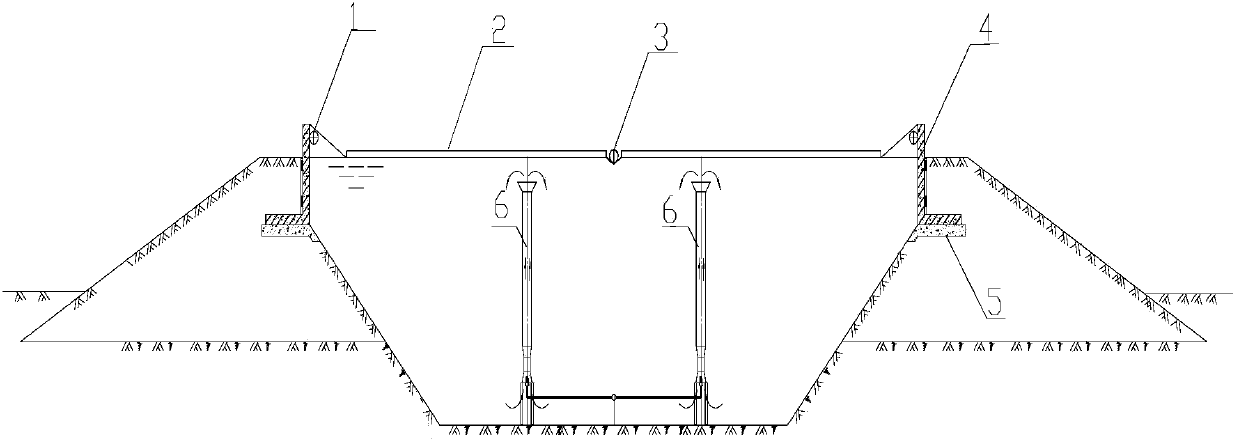

[0031] Specific embodiment three. This embodiment is a further description of the sludge anaerobic digestion reaction tank obtained by adopting a method for making an anaerobic sludge digestion reaction tank described in specific embodiment two. It also includes a drainage channel 3, The drainage channel 3 is a drainage channel pressed on the surface of the thermal insulation floating cover 2 of the counterweight pipe, and is used to remove the accumulated water on the density polyethylene thermal insulation floating cover 2 .

[0032] The sludge anaerobic digestion reaction pool with a flexible structure of the present invention is welded on site by flexible high-density polyethylene materials. The foundation pit and embankment of the flexible structure sludge anaerobic digestion reaction tank are all earthworks, and large-scale construction machinery and equipment can be used intensively for construction operations, which can greatly improve construction efficiency. The flex...

specific Embodiment approach 4

[0035] Embodiment 4. This embodiment is a further description of the sludge anaerobic digestion reaction tank obtained by adopting a method for making an anaerobic sludge digestion reaction tank described in Embodiment 2. The ring wall foundation 5 adopts reinforced concrete material.

specific Embodiment approach 5

[0036] Embodiment 5. This embodiment is a further description of the sludge anaerobic digestion reaction tank obtained by using a method for preparing an anaerobic sludge digestion reaction tank described in Embodiment 2. The prefabricated ring wall 4 adopts reinforced concrete material.

[0037] Under the same geological conditions and volume, the construction cost of the flexible structure sludge anaerobic digestion reaction tank is more than 25% lower than that of the conventional rigid structure, and the larger the volume of the reaction tank, the lower the unit volume cost.

[0038]The shape of the flexible structure sludge anaerobic digestion reaction tank is an inverted square truncated cone. The hydraulic conditions of the anaerobic digestion reaction tank with flexible structure in this shape are better, and it is convenient to arrange special upward flow sludge stirring devices at multiple points, which can make the materials in the anaerobic digestion reaction tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com