A kind of method and application of enriching anammox bacteria

An anaerobic ammonium oxidizing bacteria and enrichment technology, applied in the field of ammonia nitrogen treatment, can solve the problems of slow growth and long start-up time of anaerobic nitrogen oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

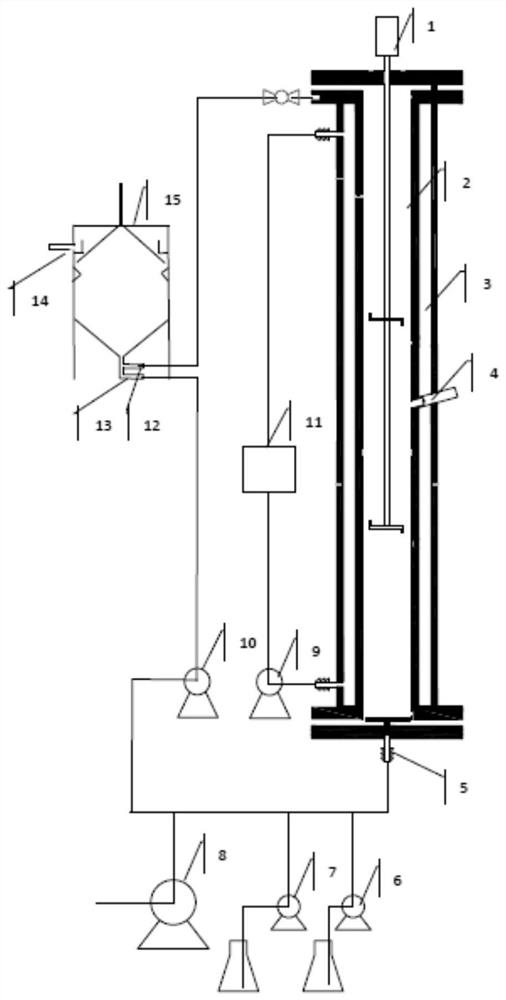

Image

Examples

Embodiment 1

[0051] step one:

[0052] Take the sludge at the bottom of the sedimentation tank in a domestic sewage treatment plant and let it stand for concentration, discard the supernatant, and take the bottom thickened sludge with a pre-configured inorganic salt solution (NaCl: 1000-1500 mg / L, KH 2 PO 4 : 10mg / L, CaCl 2 : 50mg / L, MgSO 4 : 300mg / L) for 4 times of panning, and after each panning, let stand for 1.5 hours to discard the supernatant to remove inorganic impurities and organic pollutants adsorbed on the sludge surface as much as possible. The elutriated and concentrated sludge is loaded into the UASB reactor, and the amount of sludge accounts for about 1 / 2 of the effective volume of the reactor.

[0053] Step 2:

[0054] Preparation of trace element nutrient solutions I and II:

[0055] Trace element nutrient solution I: EDTA 5000mg / L, FeSO 4 5000mg / L;

[0056] Trace element nutrient solution II: EDTA 5000mg / L, MnCl 2 ·4H 2 O 990mg / L, ZnSO 4 ·7H 2 O 430mg / L, CoCl ...

Embodiment 2

[0064] step one:

[0065] Take the sludge at the bottom of the sedimentation tank in a domestic sewage treatment plant and let it stand for concentration, discard the supernatant, and take the bottom thickened sludge with a pre-configured inorganic salt solution (NaCl: 1000-1500 mg / L, KH 2 PO 4 : 10mg / L, CaCl 2 : 50mg / L, MgSO 4 : 300mg / L) for 4 times of panning, and after each panning, let stand for 1.5 hours to discard the supernatant to remove inorganic impurities and organic pollutants adsorbed on the sludge surface as much as possible. The elutriated and concentrated sludge is loaded into the UASB reactor, and the amount of sludge accounts for about 1 / 2 of the effective volume of the reactor.

[0066] Step 2:

[0067] Preparation of trace element nutrient solutions I and II:

[0068] Trace element nutrient solution I: EDTA 5000mg / L, FeSO 4 5000mg / L;

[0069] Trace element nutrient solution II: EDTA 5000mg / L, MnCl 2 ·4H 2 O 990mg / L, ZnSO 4 ·7H 2 O 430mg / L, CoCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com