Method and system for operating a cam-driven pump

A technology for driving pumps and cams, applied in the components of pumping devices for elastic fluids, charging systems, pumps, etc., can solve problems such as damage to plunger cams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

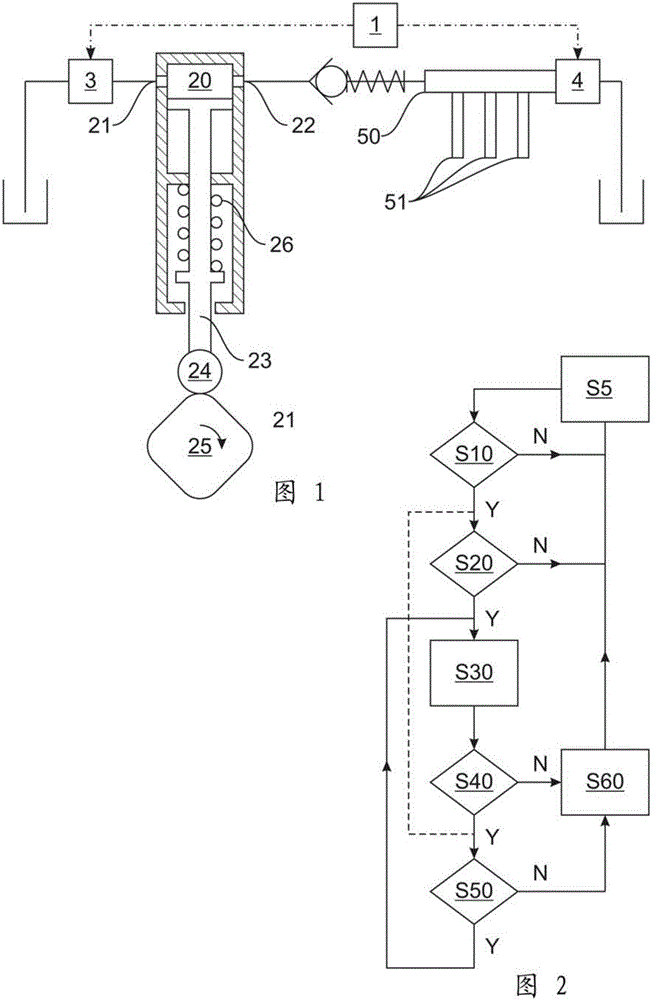

[0044] figure 1 A part of an internal combustion engine arrangement according to an embodiment of the invention is shown having an internal combustion engine comprising an injector 51 and a pump arrangement comprising a control system in the form of an ECU 1 .

[0045] The pump device comprises a cam-driven high-pressure fuel pump of a common rail system, comprising a working chamber 20 with an inlet 21 and an outlet 22, and an actuating means with a plunger 23 and a cam follower 24, said cam follower Driven by a cam 25 which is itself driven by a camshaft (not shown) of the internal combustion engine. The actuating means 23 , 24 are permanently biased towards the cam 25 by biasing means in the form of a spring 26 .

[0046] The pump device further comprises a valve device comprising an inlet valve in the form of DIV3 in fluid communication with the inlet 21 and a discharge valve in the form of PRV4 of the common rail system in fluid communication with the outlet 22 via a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com