Automatic retaining device for vehicle on ramp

A technology of stop device and ramp, applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., can solve the problem of high manufacturing matching price, and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

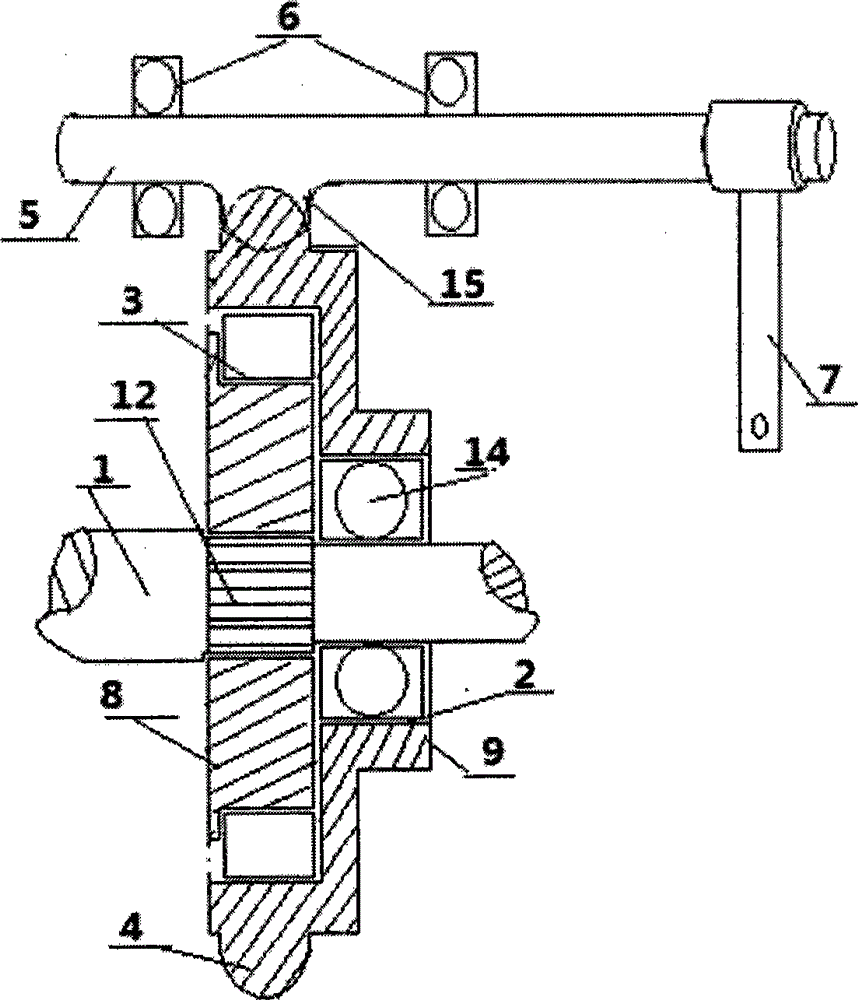

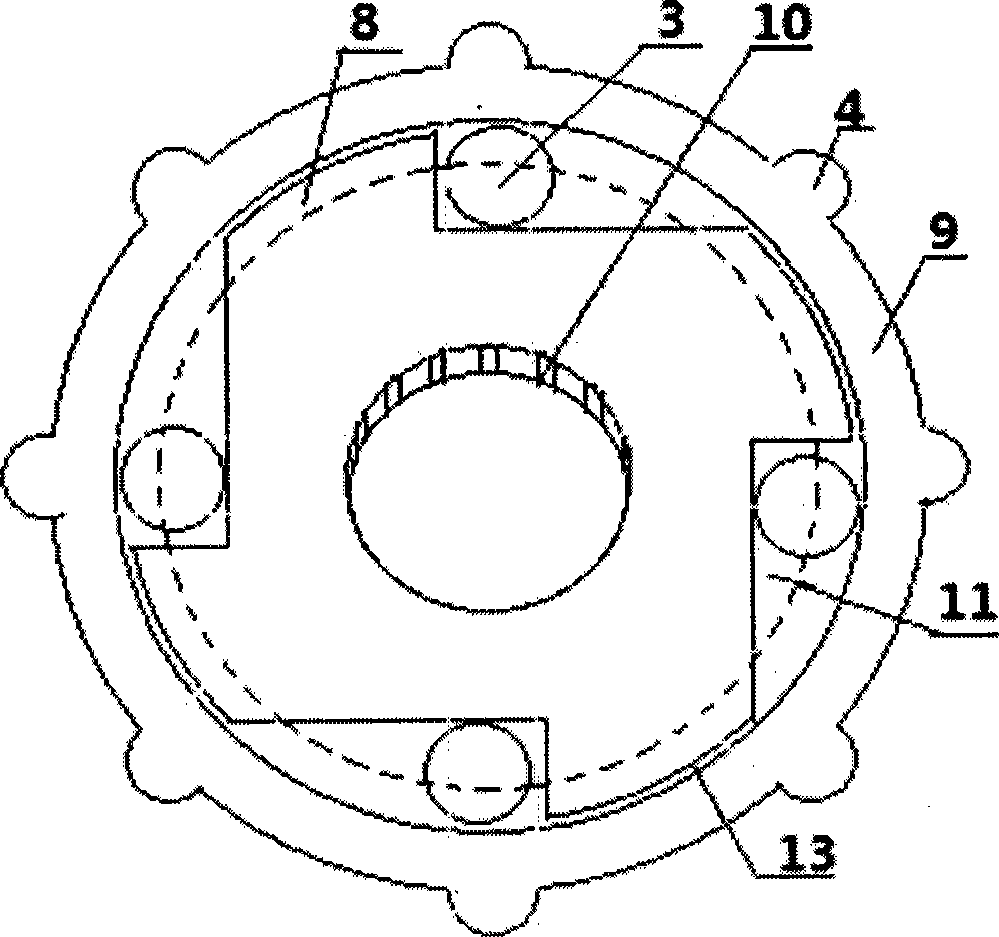

[0016] The present invention is a single structure device, as a device for preventing the vehicle from retreating, it can be installed at a certain position between the power output shaft inside and outside the gearbox to the power input shaft of the rear axle in the transmission system (electric vehicles can also be installed to one shaft of the gearbox).

[0017] Such as figure 1 figure 2 Shown, the present invention comprises power shaft 1, backstop driving disk 8, backtracking driven disk 9 and backstop joystick 5, and power shaft 1 is installed on the axle center of backstop driving disk 8 and backstop driven disk 9. A basin-shaped driven disc cavity 13 is set in the main body of the anti-retreat driven disc 9 , and the center portion of the end of the anti-retreat driven disc 9 is narrowed into a bearing hole 2 . The backstop driving disc 8 is assembled in the cavity 13 of the driven disc. The back-stop driving disk 8 is in the shape of a wind wheel, and each wind wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com