Novel inflating valve

A valve, a new type of technology, applied in the direction of functional valve types, control valves, engine components, etc., can solve the problems of rapid aging of valve cores, affecting users' use, easy tire leakage, etc., to overcome air leakage and reduce air leakage. The troublesome effect to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

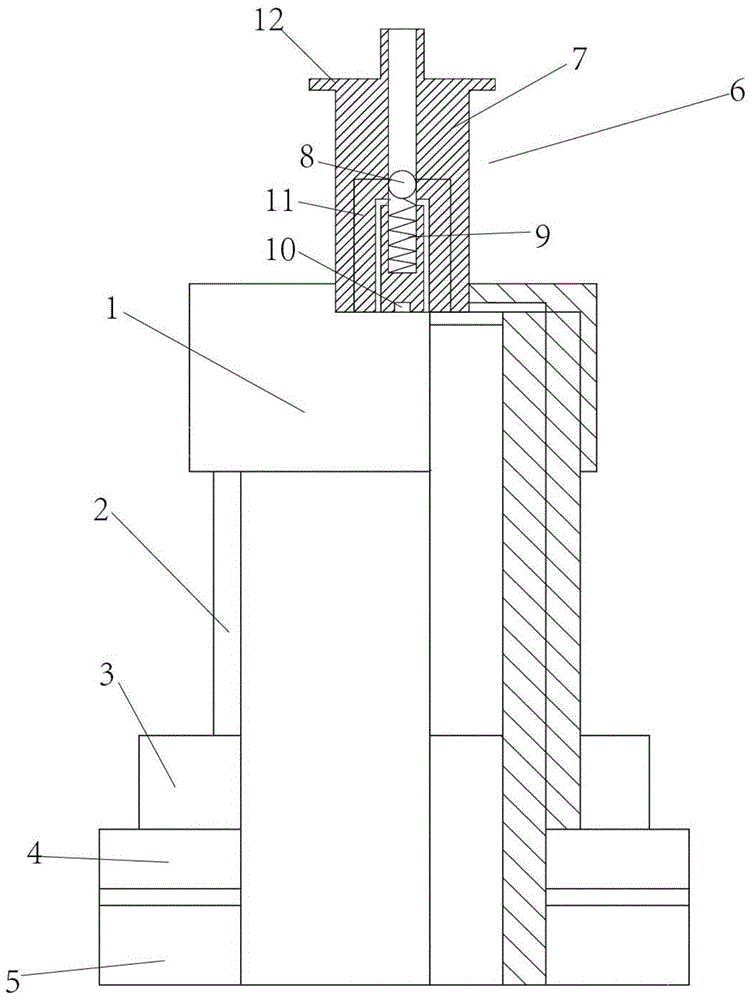

[0013] Such as figure 1 The shown valve includes a hollow valve stem 2, the lower end of the valve stem 2 is provided with an upper pressing piece 4 and a lower pressing piece 5 connected to the tire body, and the upper pressing piece 4 and the lower pressing piece 5 are respectively arranged on the tire The upper surface and the lower surface of the upper surface and the lower surface form a clamping. The outer surface of the valve stem 2 is provided with threads, and the valve stem 2 is also provided with a positioning nut 3 for positioning the valve stem 2. The positioning nut 3 is used to connect the valve stem 2 with the valve stem 2. The steel rings are locked, and a valve core 6 is arranged inside the valve stem 2, and a valve locking cover 1 is also connected to the top of the valve stem 2, and the valve core 6 includes an outer core body 61 and an inner core body 65, the outer core 61 is provided with a through hole for gas flow, the outer core 61 at the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com