Light source assembly installing structure of ceiling lamp

A technology of light source assembly and installation structure, which is applied to electric light source, light source fixing, components of lighting device, etc., can solve the problems of many operation steps, long installation time, difficult installation, etc., and achieves stable installation, less time-consuming installation, Quick and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

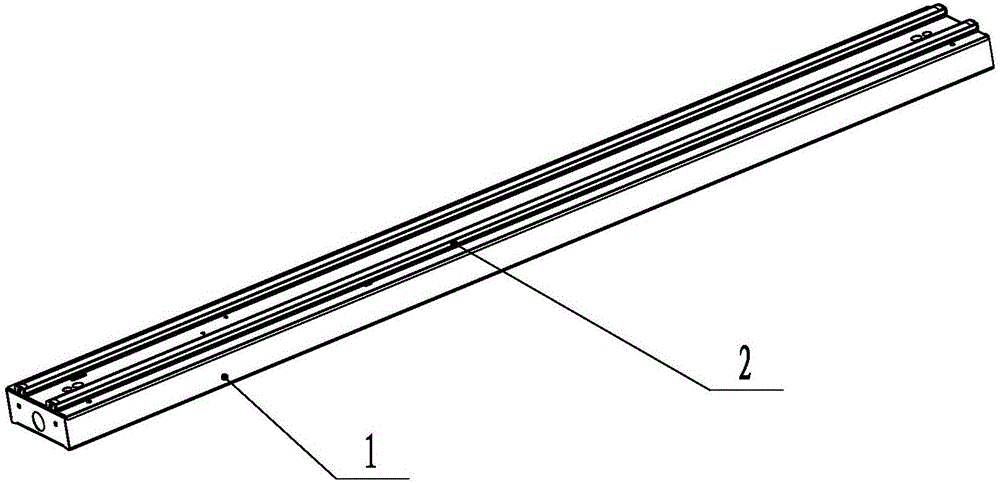

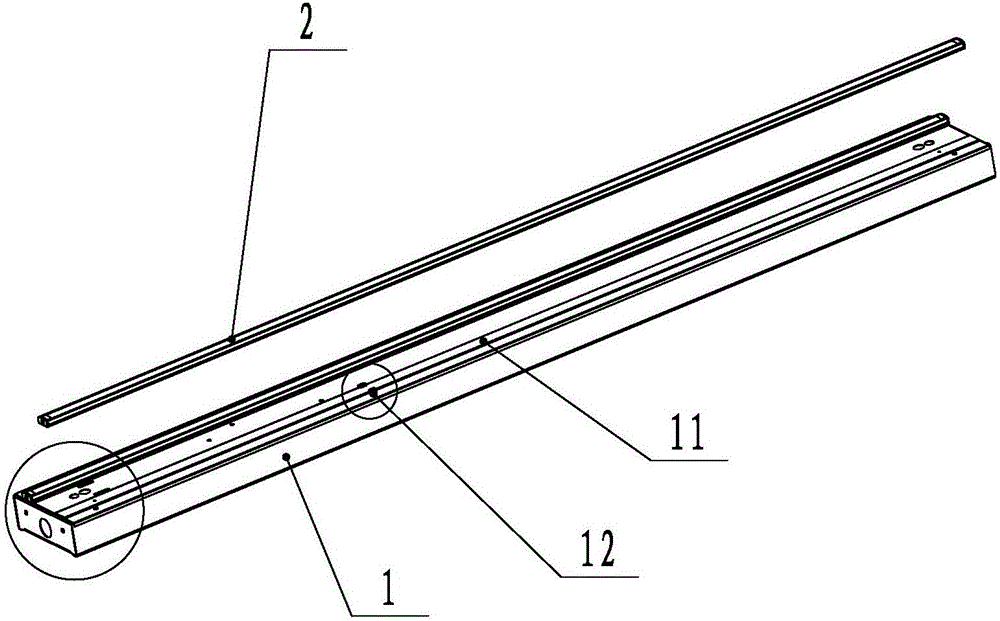

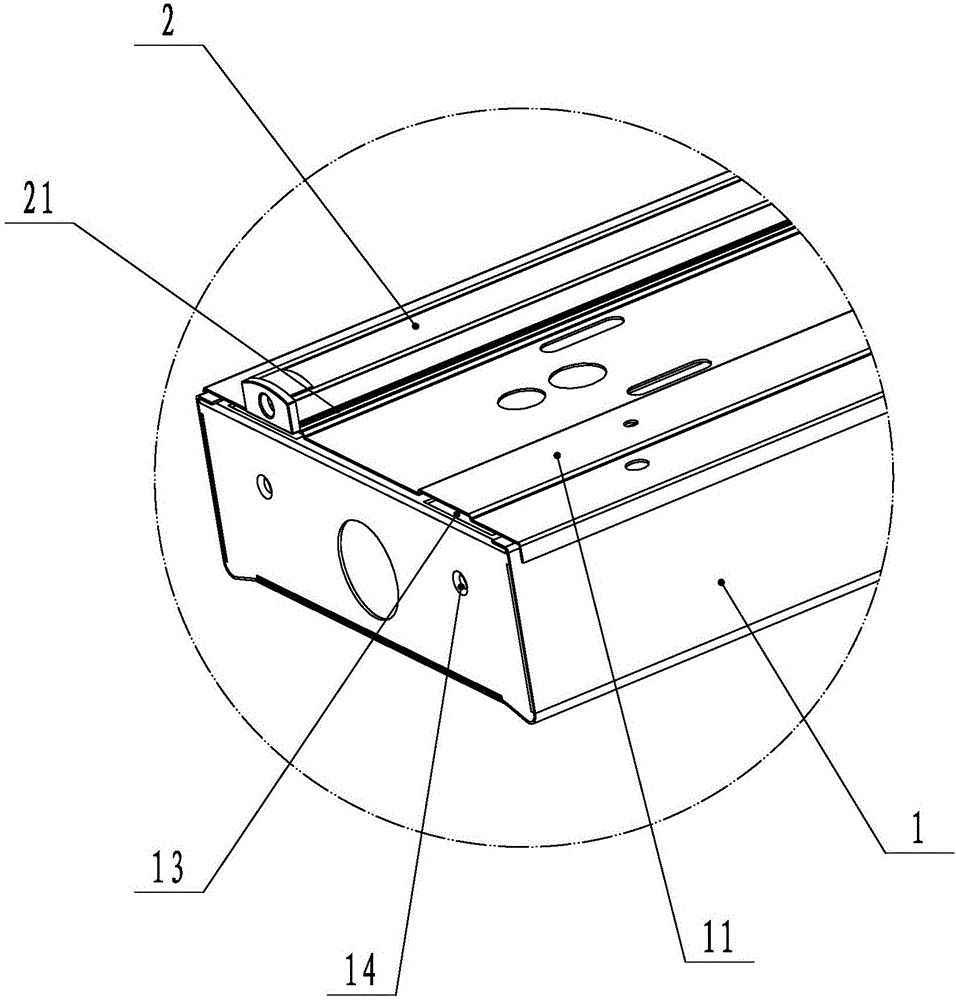

[0016] Refer to Figure 1 to 4 , A ceiling lamp light source assembly installation structure, comprising a base 1 and a light source assembly 2. The base 1 is provided with a mounting plate 11 on the upper end, the mounting plate 11 is provided with clamping blocks 12 on both sides, and the light source assembly 2 is provided with clamping slots 21 on both sides of the lower end When installing, place the light source assembly 2 on the mounting plate 11 and press it so that the block 12 is locked into the card slot 21 so that the light source assembly 2 can be installed and fixed on the base 1. The installation is quick and convenient, and the installation takes little time and greatly The installation efficiency is improved, and there is no need to turn the bolts during disassembly, which is also more convenient. At the same time, the middle part of the light source assembly 2 is fixed to the base 1 by the clamp 12, so that the installation of the light source assembly 2 is rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com