An optical system

A technology of optical system and light beam, which is applied in the field of optical system, can solve problems such as spending more time, wasting time, and not firmly pointing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

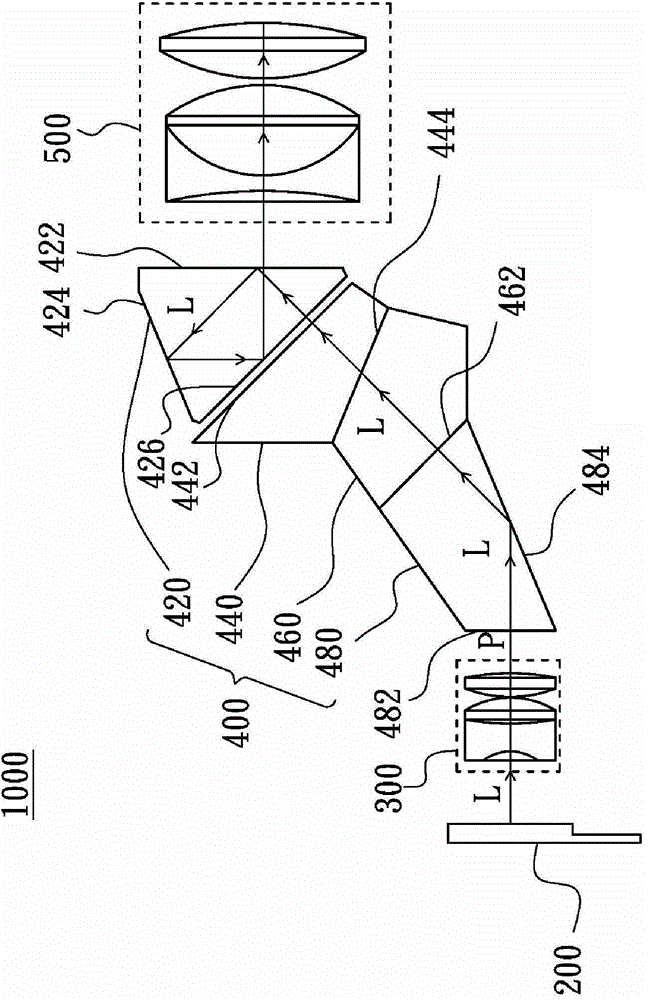

[0011] see figure 2 , which represents the optical system of the present invention. The optical system 1000 of the present invention includes a light source 200 , a focusing lens group 300 , a roof prism optical system 400 and a projection lens group 500 .

[0012] The roof prism optical system 400 includes a roof prism 420 , a first triangular prism 440 , a second triangular prism 460 and a third triangular prism 480 . The roof prism 420 has a first light exit / entry surface 422 , a roof surface 424 and a first reflective surface 426 . The first triangular prism 440 has a second reflective surface 442 and a film surface 444 , and the second reflective surface 442 is disposed adjacent to the first reflective surface 426 . The second triangular prism 460 is arranged adjacent to the film surface 444 of the first triangular prism 440 and has a second light exit / entry surface 462, and the third triangular prism 480 is adjacent to the second light exit / entry surface 462 of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com