Electric machine comprising a cooled rotor

A rotor, coolant technology used in vehicle drive trains. field, can solve problems such as reducing motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

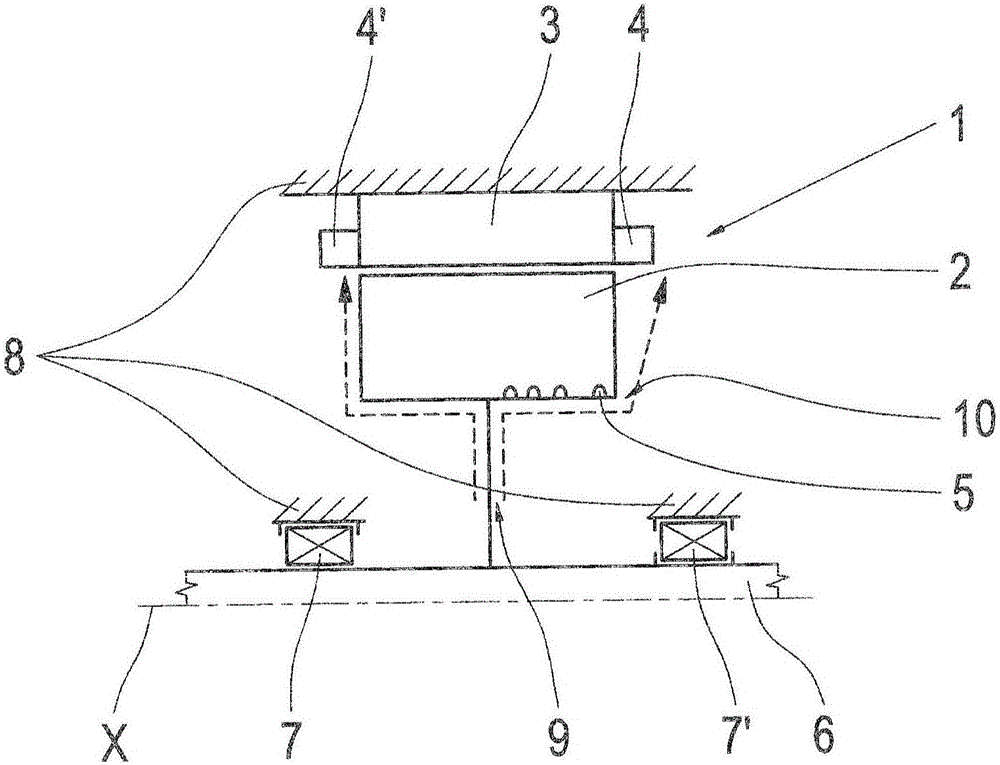

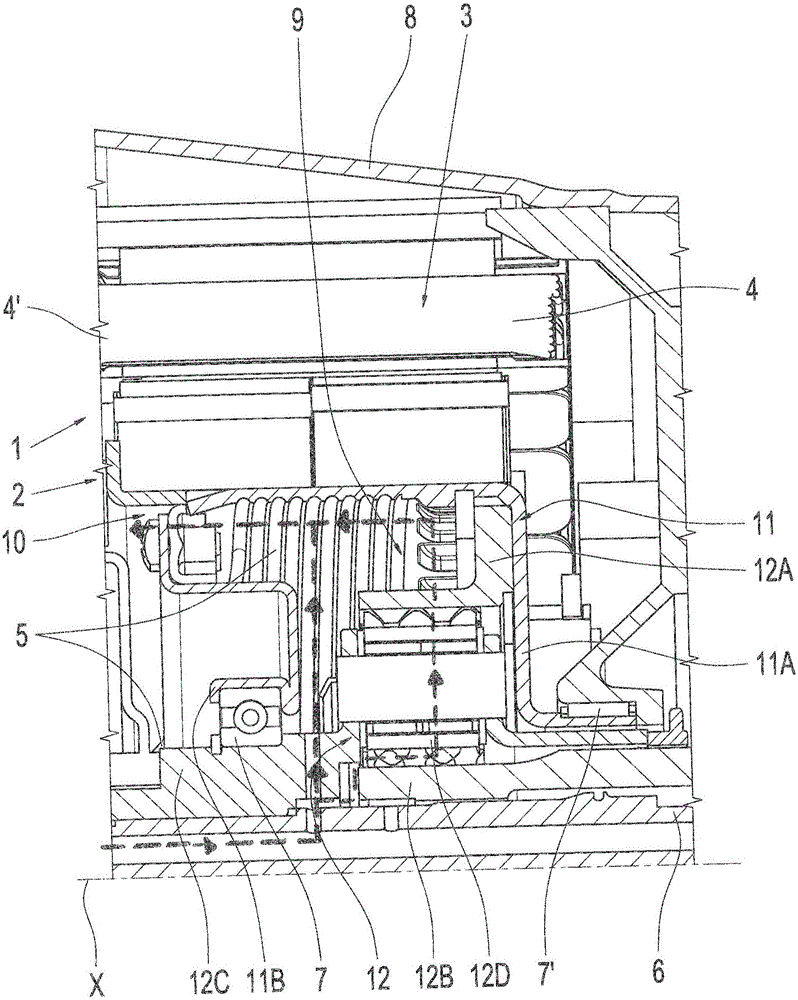

[0023] figure 1 A longitudinal section through the electric machine 1 is shown. Electric machine 1 has a stator 3 and a rotor 2 . The rotor 2 is firmly connected to the driven shaft 6 of the motor 1 . The rotor 2 and the driven shaft 6 are rotatably supported in the housing 8 of the electric machine 1 via bearings 7, 7'. The stator 3 is firmly connected to the housing 8 . The stator 3 has a plurality of electrical windings of electrical conductors, for example copper wires, and the stator 3 has winding heads 4, 4' on each axial end side. The rotor 2 is arranged radially inside the stator 3, so the motor 1 is an internal mover machine.

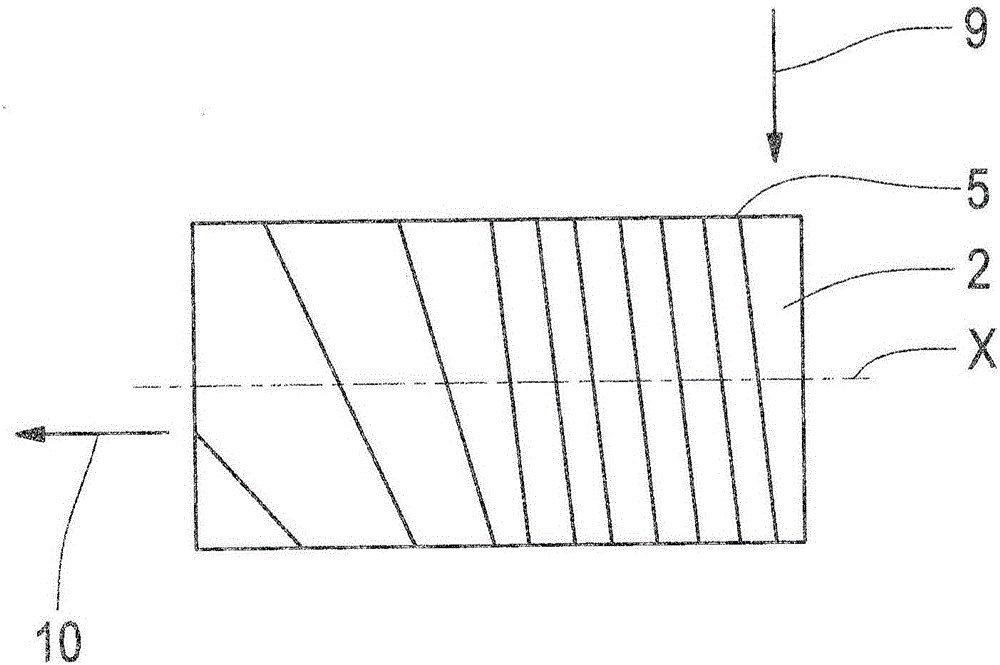

[0024] The rotor 2 has a liquid cooling with at least cooling channels 5 in the rotor 2 . The liquid cooling provides that the coolant is introduced radially from the output shaft 6 in the direction of the rotor 2 into the cooling channel 5 . The coolant flows through the flow channels 5 along the radial inner side of the rotor 2 towards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com