Automatic Transmission

An automatic transmission and low-speed technology, which is applied in vehicle gearboxes, instruments, transmissions, etc., can solve the problems of large friction loss and achieve the effects of reducing friction loss, suppressing the increase of force, and suppressing pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

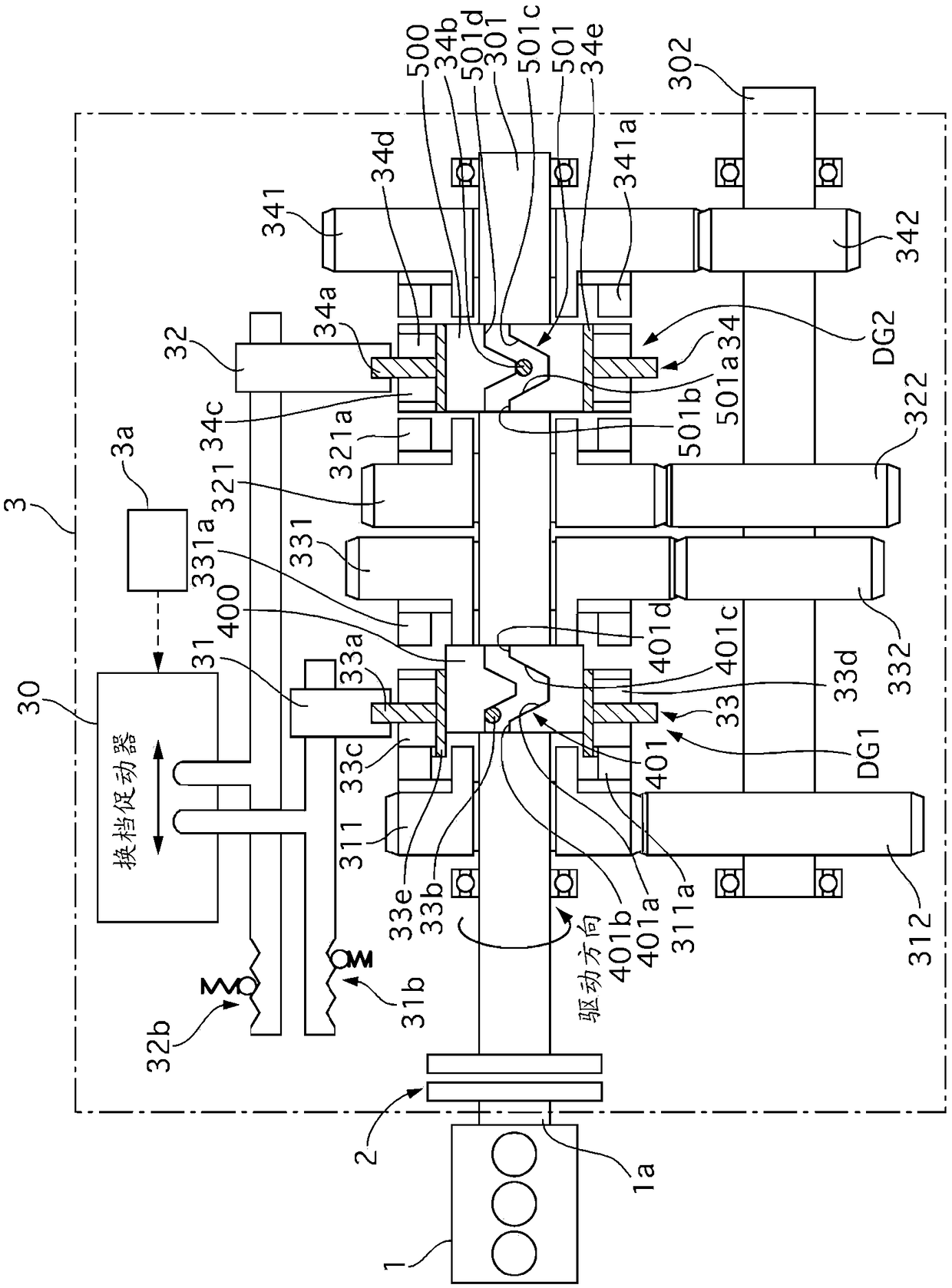

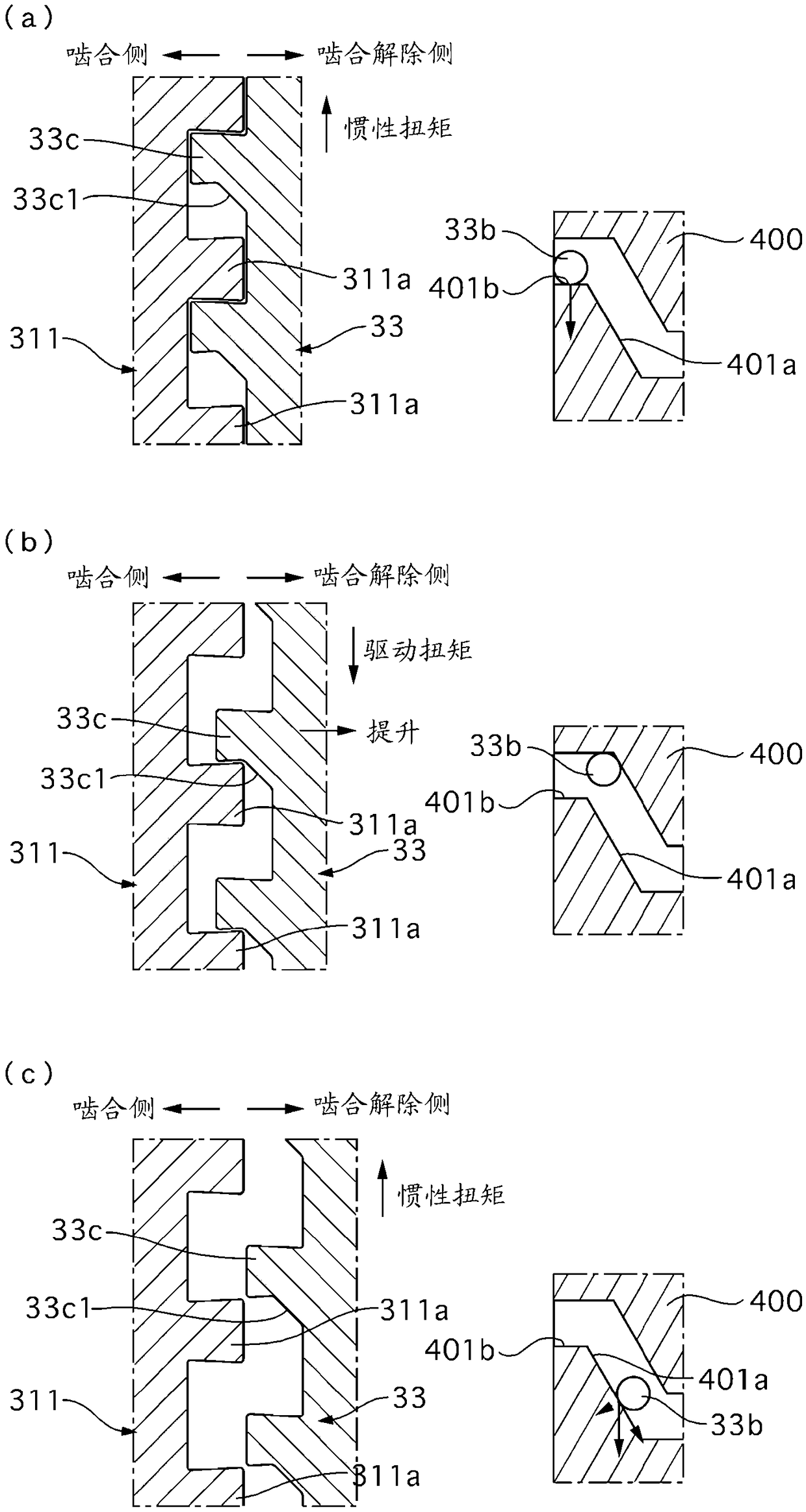

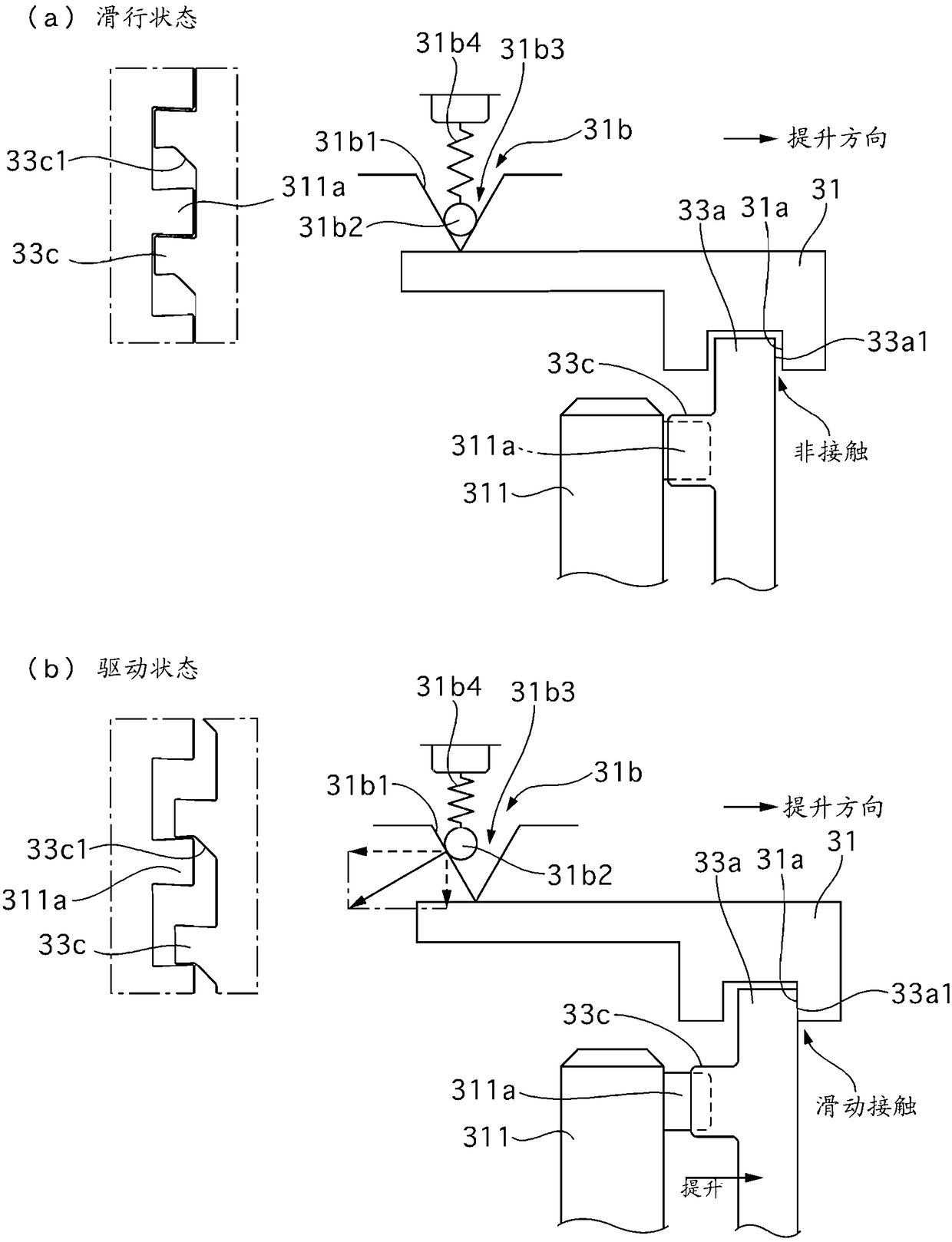

[0060] figure 1 It is a schematic system diagram showing the automatic transmission of the first embodiment. An automatic transmission 3 is connected to an engine output shaft 1 a of the engine 1 via a clutch 2 . The automatic transmission 3 has a first shaft 301 connected to the automatic transmission side of the clutch 2 , and a second shaft 302 arranged in parallel to the first shaft 301 . On the first shaft 301, there are a first-speed drive gear 311 (corresponding to a first low-speed gear), a second-speed drive gear 321 (corresponding to a first high-speed gear), and rotatably supported relative to the first shaft 301 . 3rd speed drive gear 331 and 4th speed drive gear 341 . On the second shaft 302, there are a first-speed driven gear 312 (corresponding to the second low-speed gear) and a second-speed driven gear 322 (corresponding to the second high-speed gear), which are fixed on the second shaft 302 and rotate integrally with the second shaft 302 . gear), 3-speed d...

Embodiment 2

[0090] Next, Example 2 will be described. Since the basic configuration is the same as that of Embodiment 1, only the points of difference will be described. Figure 6 It is a schematic sectional view showing the structure of the positioning groove of the second embodiment. In Example 1, the second urging slope 31b12 has an inclination angle θ2. In contrast, the inclination angle of the lifting position is set to 0, in other words, a flat surface 31b13 parallel to the lifting direction is formed, and a third biasing inclined surface 31b14 having a predetermined inclination angle is formed on the flat surface 31b13. As a result, after the first clutch claw 33c for the first speed is lifted, the flat surface 31b13 contacted by the check valve ball 31b2 exerts all the urging force of the elastic body 31b4 in the direction perpendicular to the lifting direction, so that it is possible to further suppress the The pressing force between the right inner side surface 31a of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com