Tetrahedral mesh virtual cutting method based on route separation

A technology of tetrahedral mesh and cutting method, applied in the field of computer science, can solve problems such as complex steps, slow finite element calculation, violation of the law of conservation of mass, etc., to achieve the effect of improving stability and maintaining calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

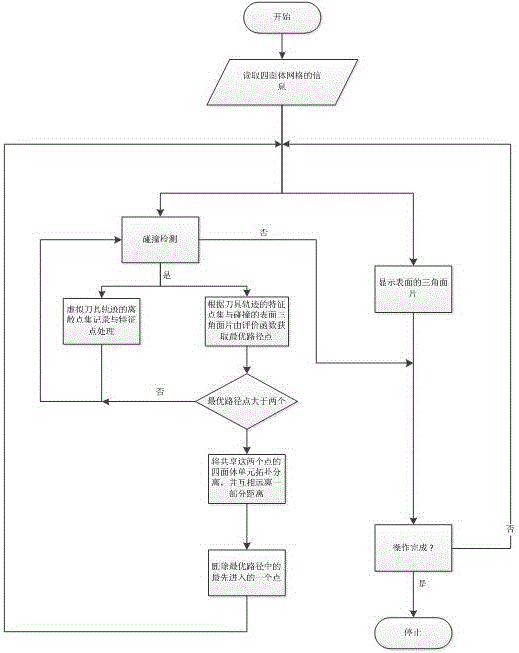

[0022] In order to describe the present invention more specifically, the tetrahedral grid virtual cutting method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, a virtual cutting method of tetrahedral mesh based on path separation includes the following steps.

[0024] (1) Read the data of the tetrahedral grid to obtain the surface triangular patch set of the tetrahedral grid;

[0025] Read the tetrahedral data, and generate a collection of tetrahedral meshes, a collection of triangular patches, and a collection of points.

[0026] (2) The thread that starts the collision detection and the thread that assembles the triangles on the display surface to the screen;

[0027] Start two threads, which are always running during the whole process of operation, and the threads will not exit until the user stops using the program. They are the collision detection thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com