Ultrasonic liquid level meter based intelligent water fountain system and working method

A working method and water dispenser technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of reduced temperature control sensitivity, affecting drinking water quality, and insufficient freshness of water quality, so as to ensure freshness and quality, and reduce occupation. The effect of large space and water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

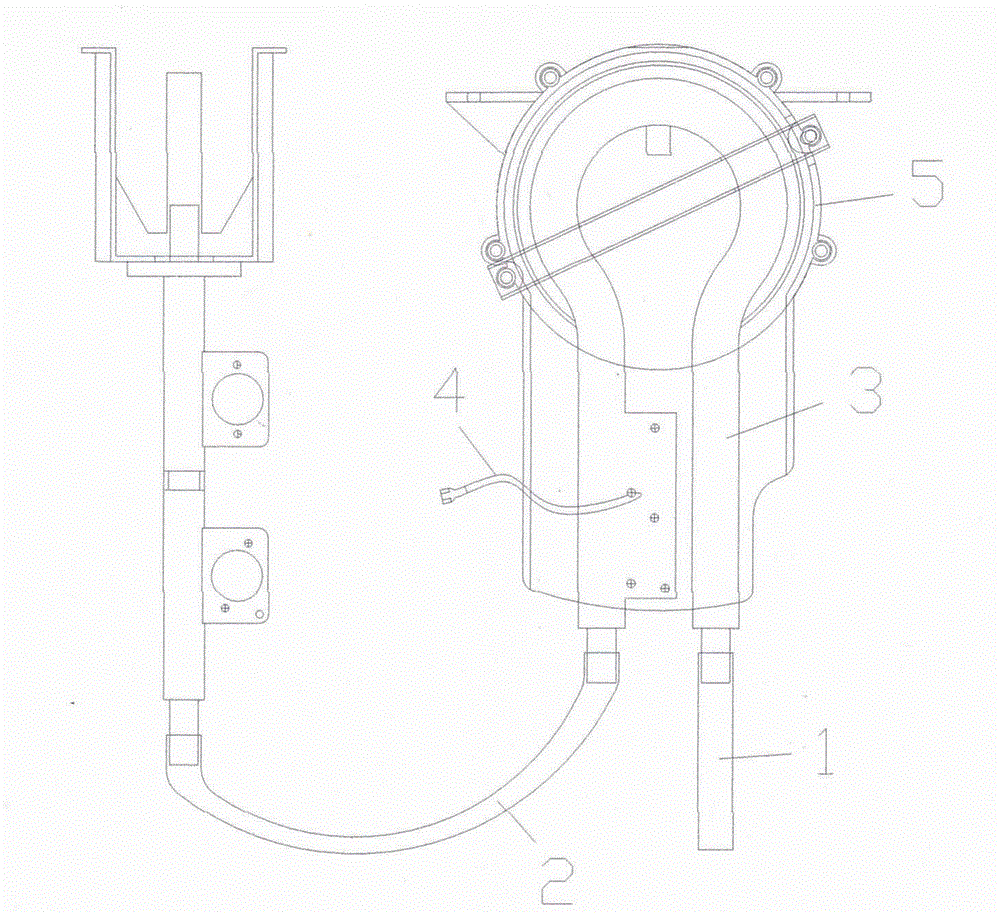

[0012] refer to figure 1 As shown, an intelligent water dispenser system and working method based on an ultrasonic liquid level gauge of the present invention includes a water inlet connector 1, a water outlet connector 2 and a heating system 3, and one end of the water inlet connector 1 is connected to a tank containing drinking water , the other end is connected to the heating system 3, one end of the water outlet joint 2 is connected to the heating system 3, and the other end is connected to the water outlet tank, the drinking water introduced through the water inlet joint 1 is quickly heated through the heating system 3, and then connected to the water outlet joint 2 out to drink.

[0013] In a preferred embodiment of the present invention, the heating system 3 is a curved hollow elbow. The heating system 3 is used to maintain the communication between the water inlet joint 1 and the water outlet joint 2 on the one hand, and is used for rapid heating on the other hand. dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com