Environment-friendly disperse itubin mixed component and disperse dye

A technology for dispersing red jade and mixing components, which is applied in the field of fine chemistry and can solve the problems that the content of heavy metals cannot meet environmental protection indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

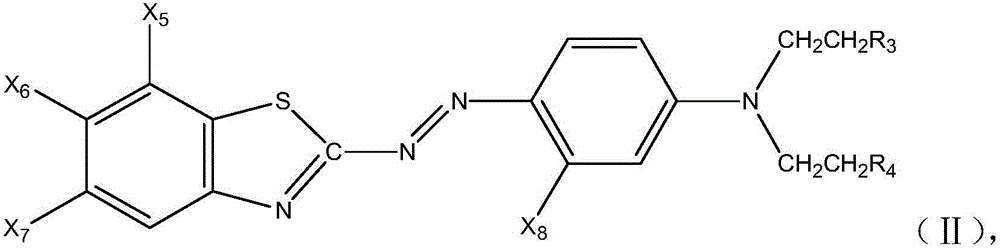

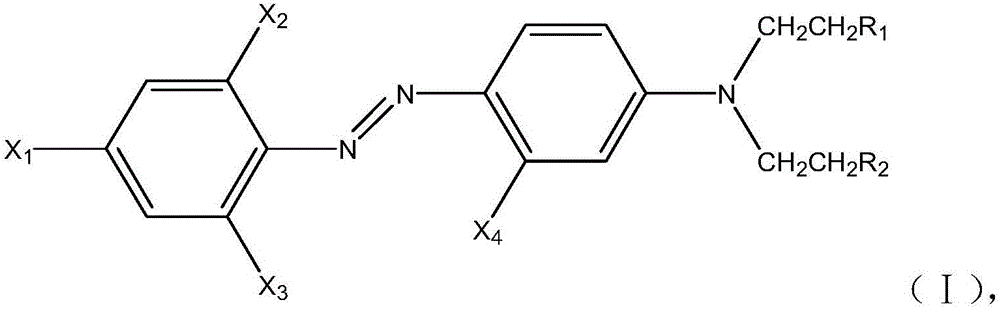

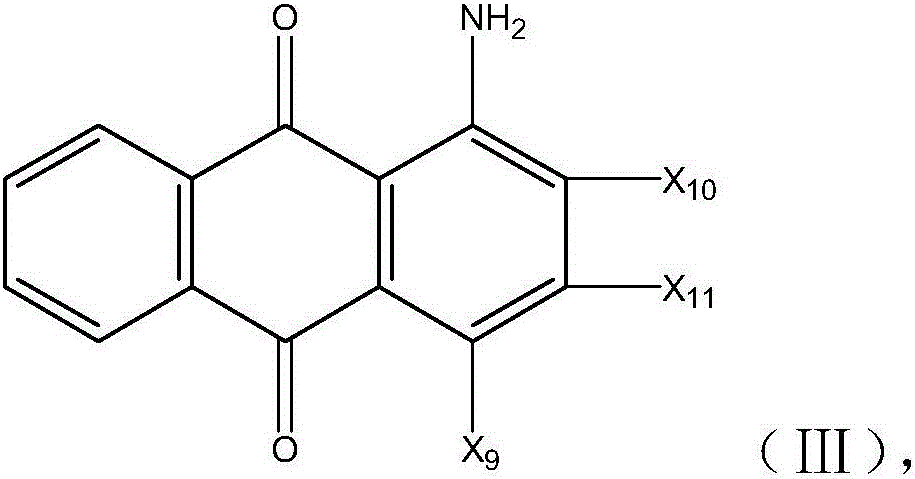

Method used

Image

Examples

Embodiment 1

[0028] With 12 gram formula (I-2) and 15 gram formula (I-5) component A, 3 gram formula (II-3) component B, 4 gram formula (III-7) component C, 20 Add 85 grams of dispersant 85A and 46 grams of dispersant MF, add water and stir evenly, sand grind with a sand mill until the dispersibility meets the requirements, then filter and spray dry to obtain the finished dye.

Embodiment 2

[0030] Component A of 13 grams of formula (I-9), component B of 20 grams of formula (II-5), component C of 3 grams of formula (III-5), 25 grams of dispersant 85A and 39 grams of dispersant MF, add water and stir evenly, sand grind with a sand mill until the dispersibility meets the requirements, then filter and spray dry to get the finished dye.

Embodiment 3~8

[0032] According to the data shown in Table 1, add water to component A, component B, component C and additives, stir evenly, use a sand mill to grind until the dispersibility meets the requirements, and then filter and spray dry to obtain the dye finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com