Hydraulic reciprocating seal dynamic property detection device and design

A technology of dynamic performance and monitoring device, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problem of dynamic performance detection of hydraulic reciprocating seal, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1. Hydraulic reciprocating seal dynamic performance monitoring device

[0038] The device can detect the dynamic performance of the hydraulic reciprocating seal without changing the normal operating state of the hydraulic actuator, and can realize the hydraulic reciprocating seal contact strain signal, fluid pressure signal, oil leakage and The collection of tension pressure signal and displacement signal during the movement of the actuator, through the method of multi-sensing information fusion, realizes the friction and leakage performance detection of hydraulic reciprocating seals, and provides a basis for improving the reliability of hydraulic reciprocating seals.

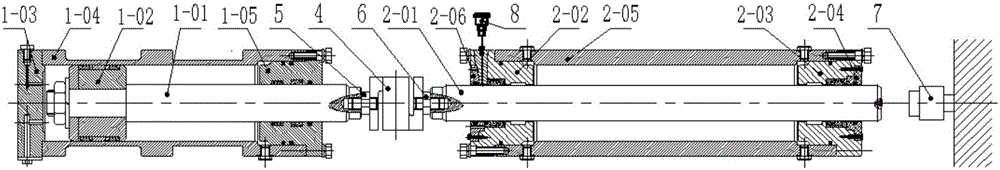

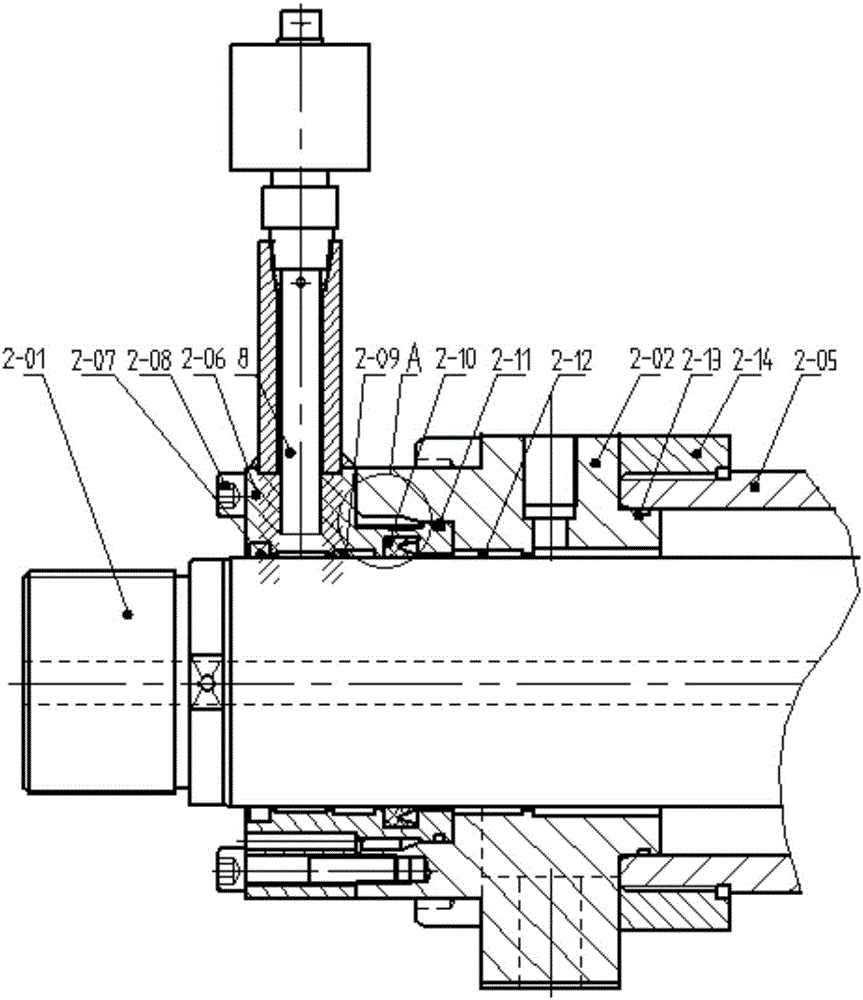

[0039] The structure of the device is as Figure 1 to Figure 9 As shown, according to the detection content, it is divided into two modules, the dynamic friction performance detection module and the leakage performance detection module.

[0040] The dynamic friction performance detection module ...

Embodiment 2

[0045] Embodiment 2. Design of hydraulic reciprocating seal dynamic performance monitoring device

[0046] The dynamic performance monitoring device of the hydraulic reciprocating seal is designed according to the following method. The design of the device is divided into the design of the dynamic friction performance detection module and the leakage performance detection module.

[0047] 1. Piston rod seal dynamic friction performance detection module:

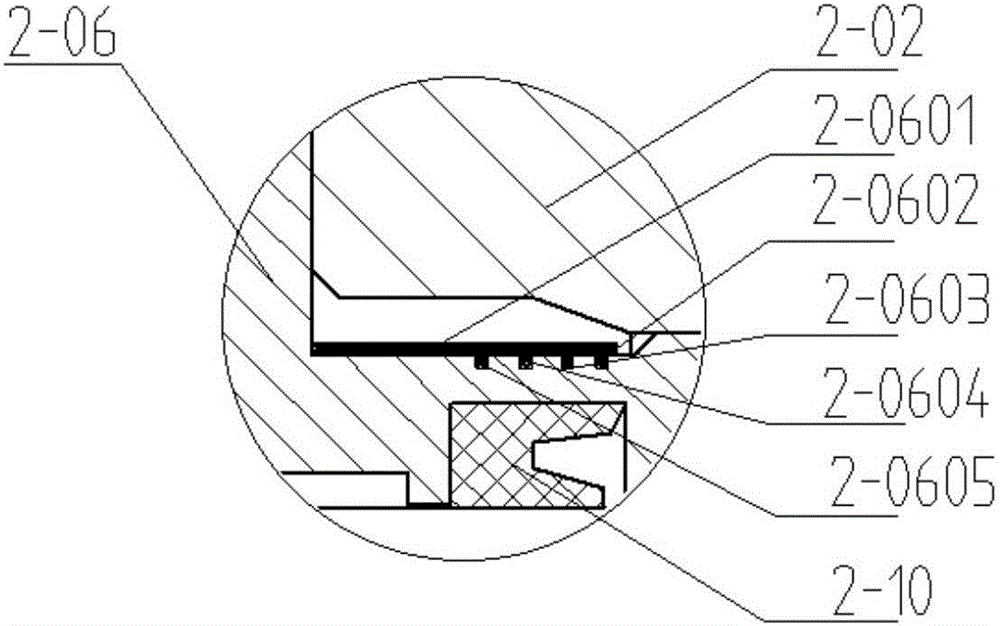

[0048] (1) Structural design of the dynamic friction performance detection module of the piston rod seal:

[0049] In order to accurately measure the frictional force of the piston rod seal, the first test cylinder 2 is in the form of a double-acting cylinder. Since the material of the piston rod seal is one of the variable parameters of the test, in order to facilitate the disassembly of the seal, the piston rod seal is installed on the gland. Every time the piston rod seal is disassembled, only the gland on the cylinder he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com