Improved anti-backflow high-pressure pipe fitting

An improved anti-backflow technology, applied in the direction of pipe components, pipes/pipe joints/fittings, functional valve types, etc., can solve the problems of high fluid momentum and cannot automatically prevent backflow, etc., to achieve accelerated and fast closure, good application prospects, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

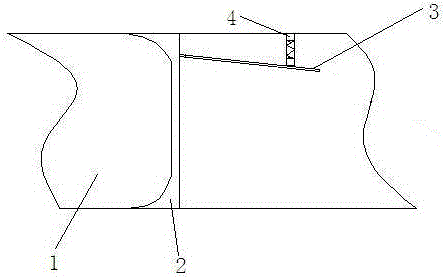

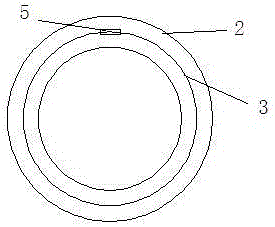

[0016] Such as figure 1 with 2 As shown, an improved anti-backflow high-pressure pipe fitting, including a pipe fitting body 1, is characterized in that the input end of the pipe fitting body 1 is provided with an annular structure 2, and the side of the annular structure 2 facing the input end adopts a circular arc shape Designed to gradually reduce the mouth area of the ring structure, which can slow down the impact of the fluid on the ring groove. A baffle 3 is provided on the side of the ring structure 2 facing away from the input end, and the upper end of the baffle 3 is fixed on the ring through a hinge 5. In structure 2, a spring device 4 that expands and contracts in the up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com