Distributed tubular heat exchanger control system

A tube heat exchanger and control system technology, which is applied in heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of reducing calculation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0014] Application Scenario 1:

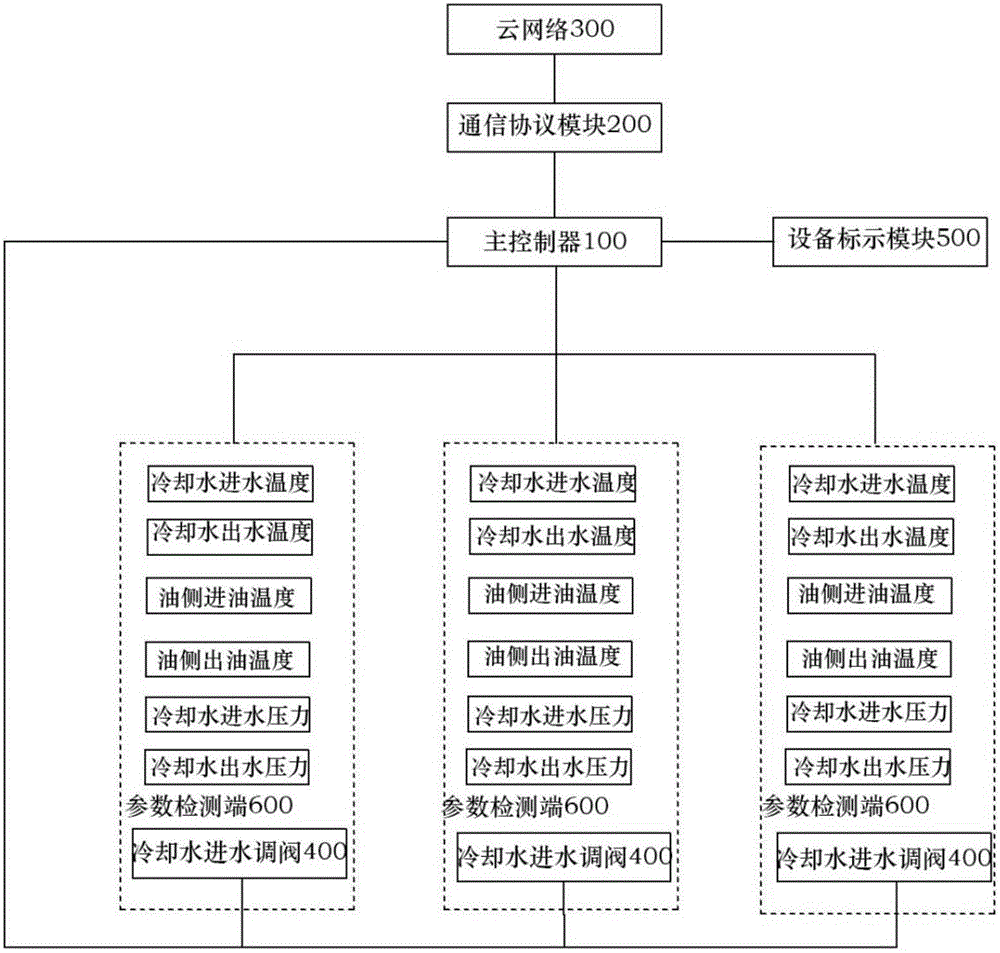

[0015] Such as figure 1 A distributed tube heat exchanger control system is shown, which is used to detect and control multiple distributed tube heat exchangers, including a parameter detection terminal 600, a main controller 100, a communication protocol module 200, and a cloud network 300 , the cooling water inlet regulating valve 400 and the equipment marking module 500; the parameter detection terminal 600 is used to detect the cooling water inlet temperature, the cooling water outlet temperature, the oil side oil inlet temperature, and the oil side oil outlet of the tubular heat exchanger Temperature, cooling water inlet pressure and cooling water outlet pressure, and the detected data are sent to the main controller 100, and the main controller 100 uploads the data to the cloud network 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com