Interlock mechanism, electric control equipment and circuit breaker equipped with the interlock mechanism

A technology of interlock mechanism and lock, applied in the direction of circuit, protection switch operation/release mechanism, electrical components, etc., can solve problems such as low production efficiency and product yield, and inability to adjust bimetallic strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

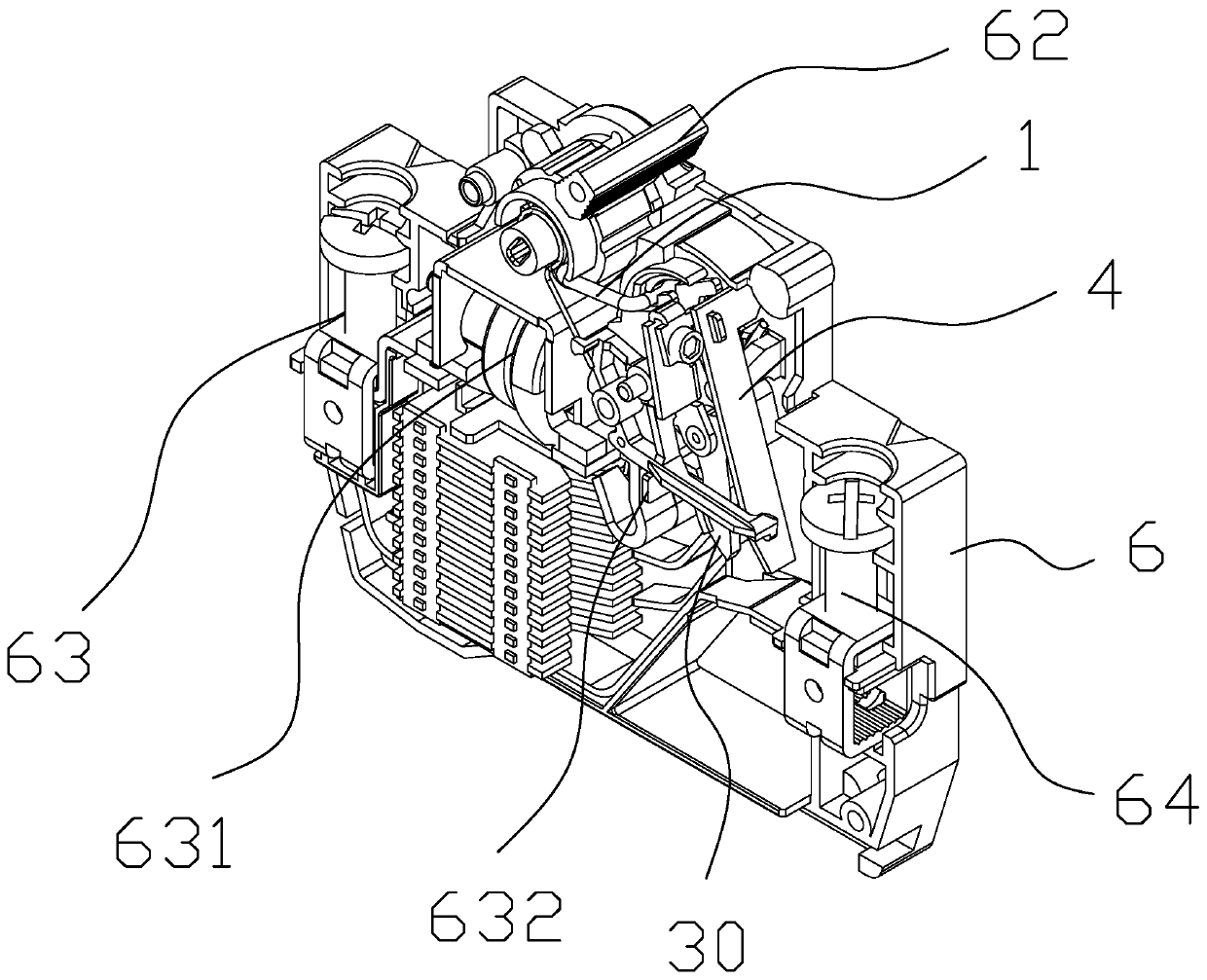

[0038] refer to figure 1 As shown, this embodiment is a circuit breaker, which, like existing circuit breakers, includes a housing 6, usually made of plastic, which is composed of two half-shell structures snapped together (for clarity expression, a half-shell structure is removed in the figure), the housing 6 is installed with a first terminal 63, a magnetic assembly 631, a static contact 632, an interlock mechanism, and a second terminal 64; the first terminal 63 , the magnetic assembly 631 and the static contact 632 are electrically connected in series in sequence, and the second terminal 64 is electrically connected to the free end of the bimetal 4 of the interlock mechanism through a conductive copper sheet and a soft connection copper wire to form a controllable Wiring group.

[0039] The housing 6 is also installed with an operating member 62. In this embodiment, the operating member 62 is a knob pivotally connected to the housing 6, and the second end of the interlock m...

Embodiment 2

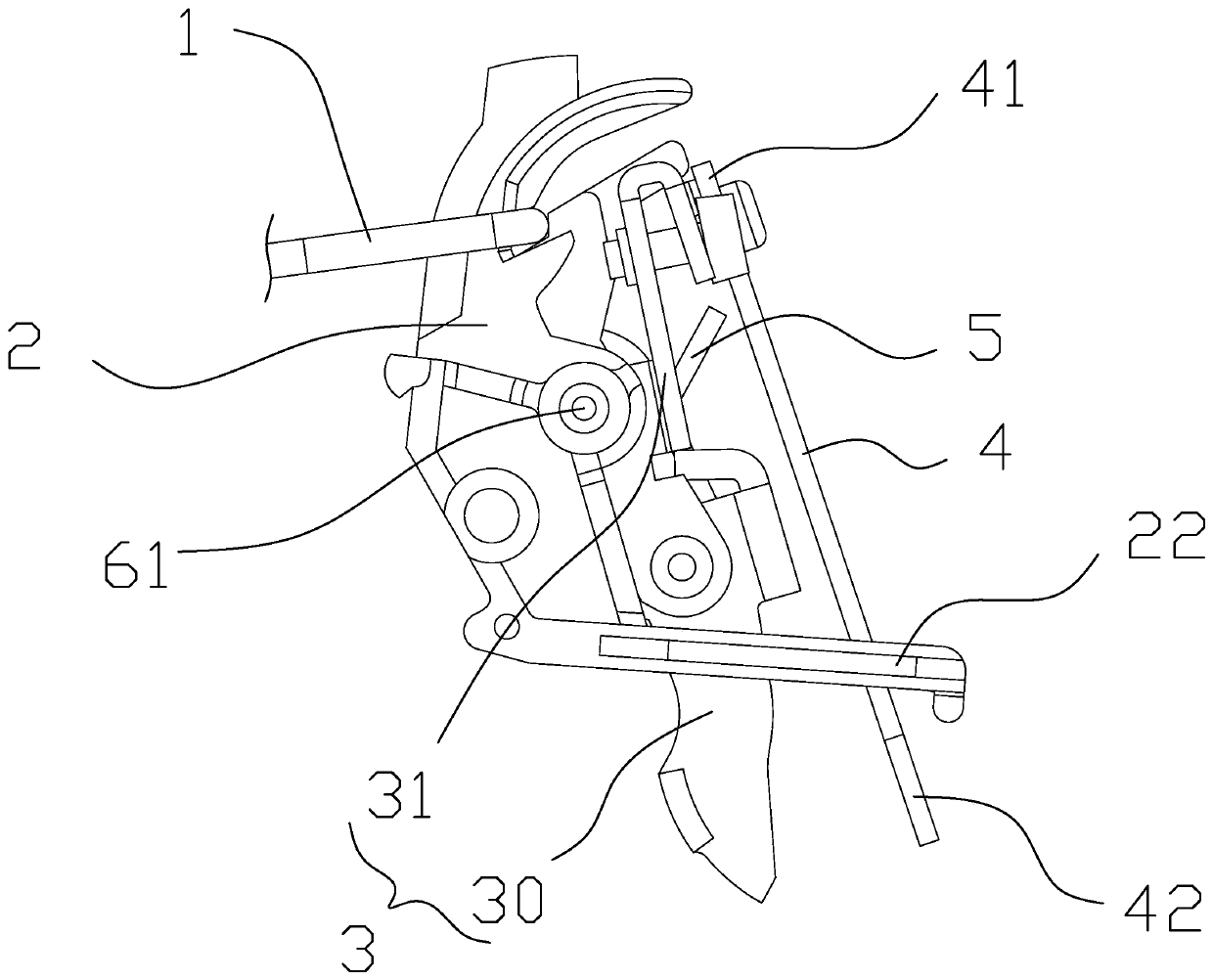

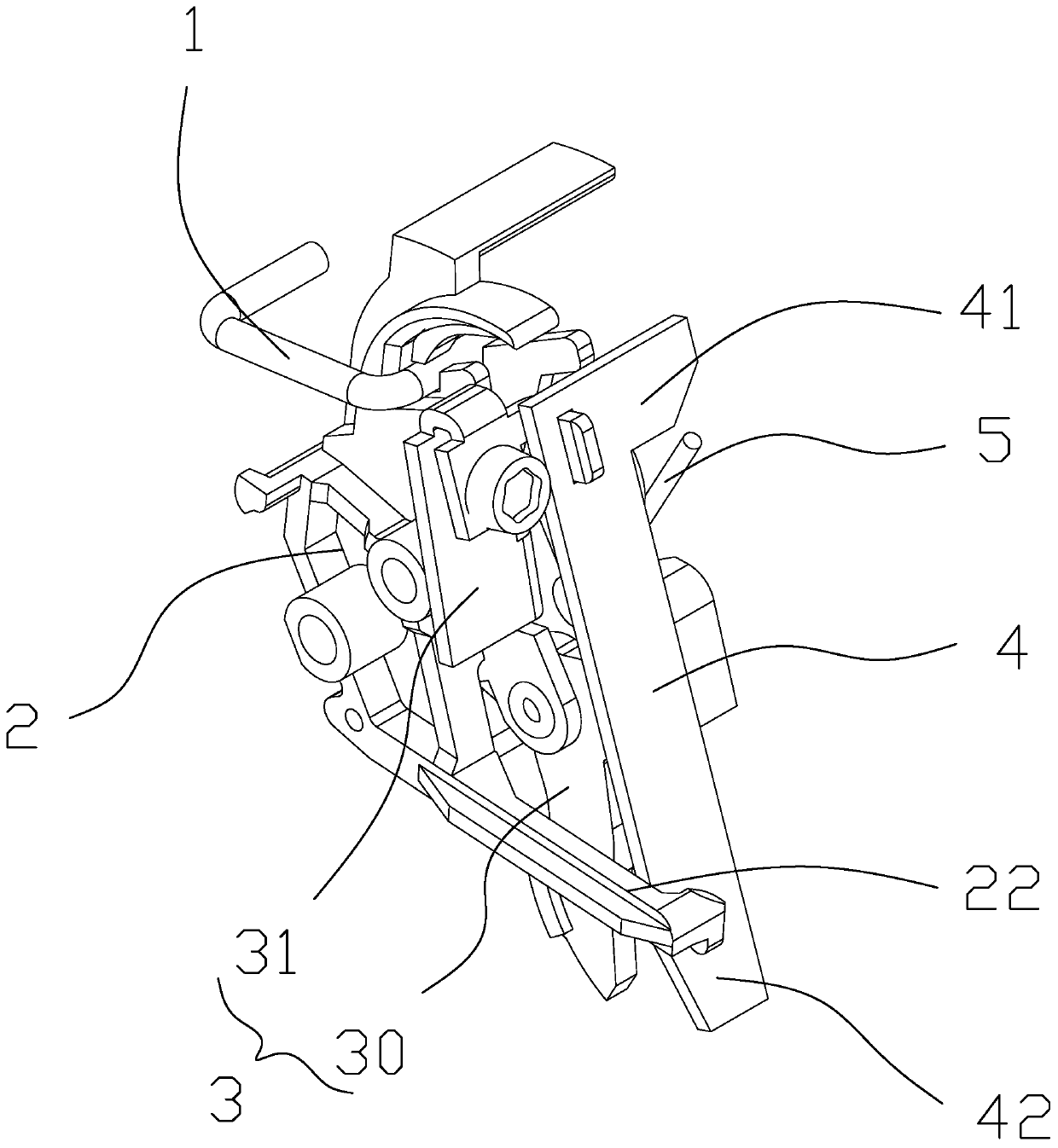

[0054] See 7 to Figure 10 , the interlock mechanism and the circuit breaker of this embodiment are basically the same as the first embodiment, the main difference is that the adjustment structure in the interlock mechanism of this embodiment is slightly different, the adjustment structure in the interlock mechanism of this embodiment is specifically : the adjustment part is a bracket 33 connected to the main body 311 of the moving contact assembly 30, and the main body 311 is basically in an "L" shape, and the fixed end 41 of the bimetal 4 is positioned on the bracket 33, The adjustment component adjusts the position of the bimetal 4 on the bracket 33 to change the relative distance between the bimetal 4 and the main body 311 of the moving contact assembly 30, thereby changing the free position of the bimetal 4. The relative position of end 42 and drive arm 22.

[0055] In this embodiment, the fixed end 41 of the bimetal 4 defines a mounting hole 410 , and the fixed end 41 o...

Embodiment 3

[0061] This embodiment is improved on the basis of Embodiment 2, and the retaining spring as the elastic member 7 of this embodiment is adjusted and designed (to become a retaining spring with an arcuate structure), so that the deformation occurs as an arcuate change, Thereby the bimetal 4 conflicts with the arc surface of the structural circlip, and the adjusting part adjusts the position of the bimetal 4 in the bracket 33 to change the arc (the nut position is adjusted to make it elastically deformed), so as to change The relative angular relationship between the bimetal 4 and the main body 311 of the moving contact assembly 30 (same as the embodiment 1, the angular swing occurs), thereby changing the relative relationship between the free end 42 of the bimetal 4 and the driving arm 22 Location.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com