Switching controller and method of controlling switching operating frequency of a power converter

A technology of power converters and switch controllers, which is applied in the direction of high-efficiency power electronic conversion, conversion equipment without intermediate conversion to AC, control/regulation systems, etc., and can solve problems such as efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description is merely exemplary in nature, and is not intended to limit the invention, application or use.

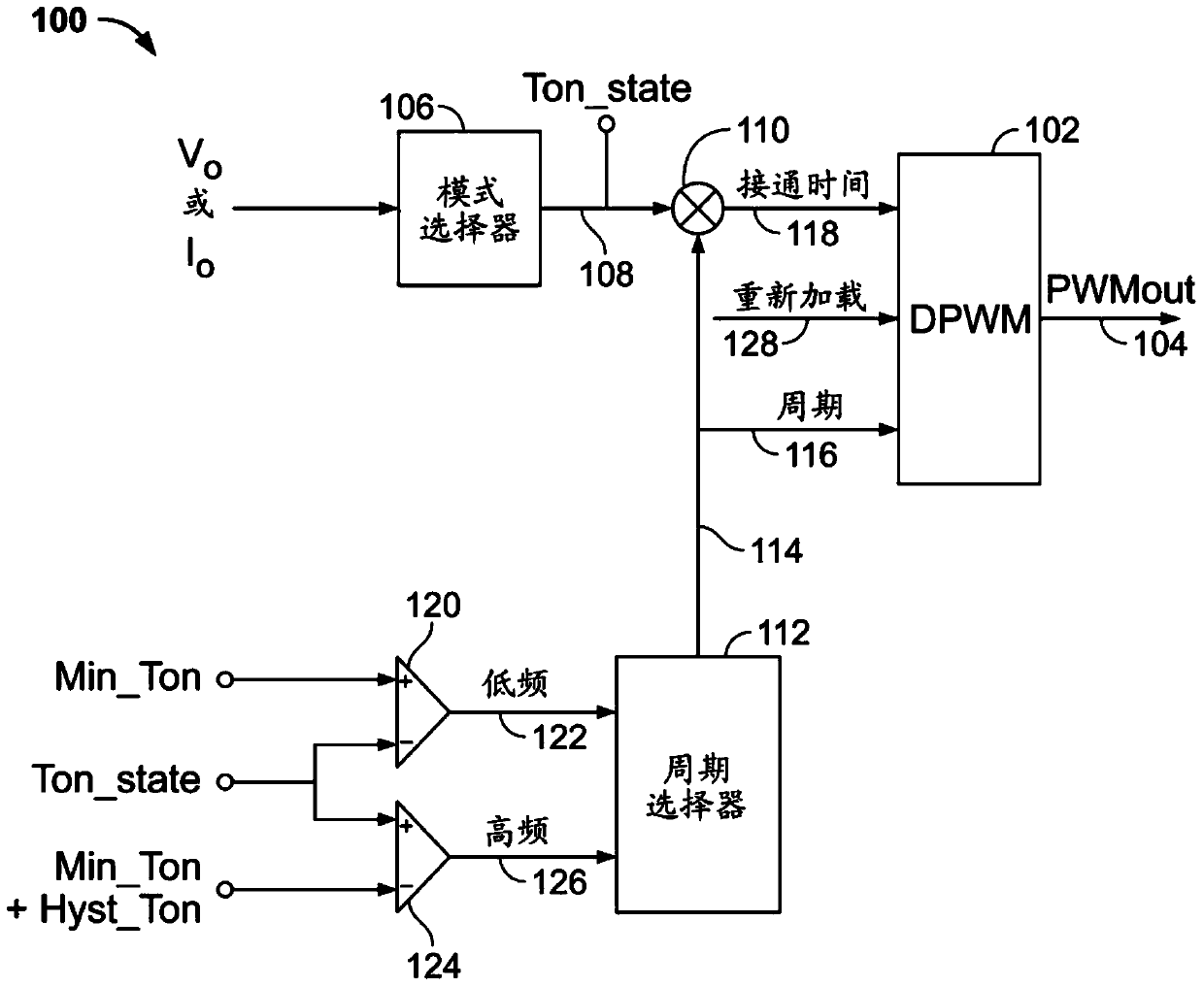

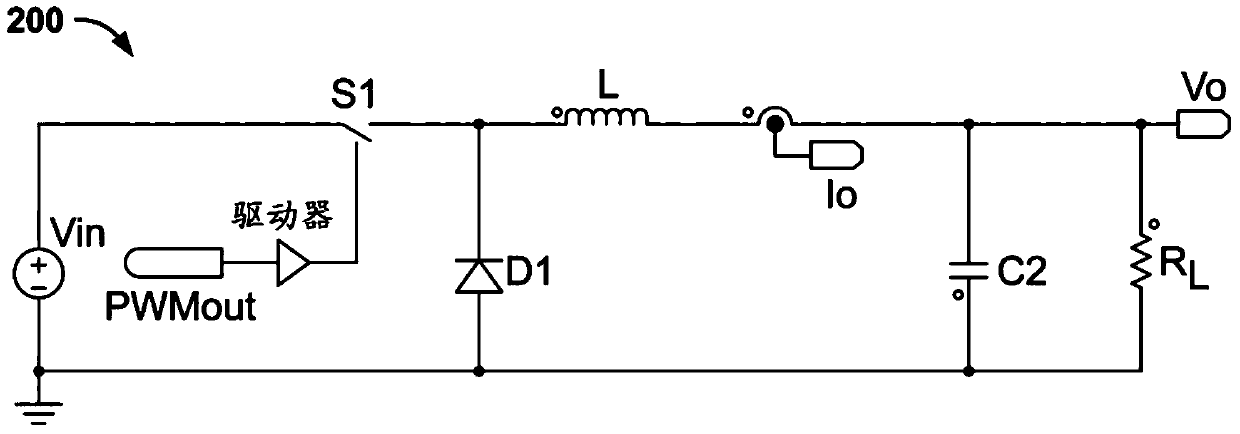

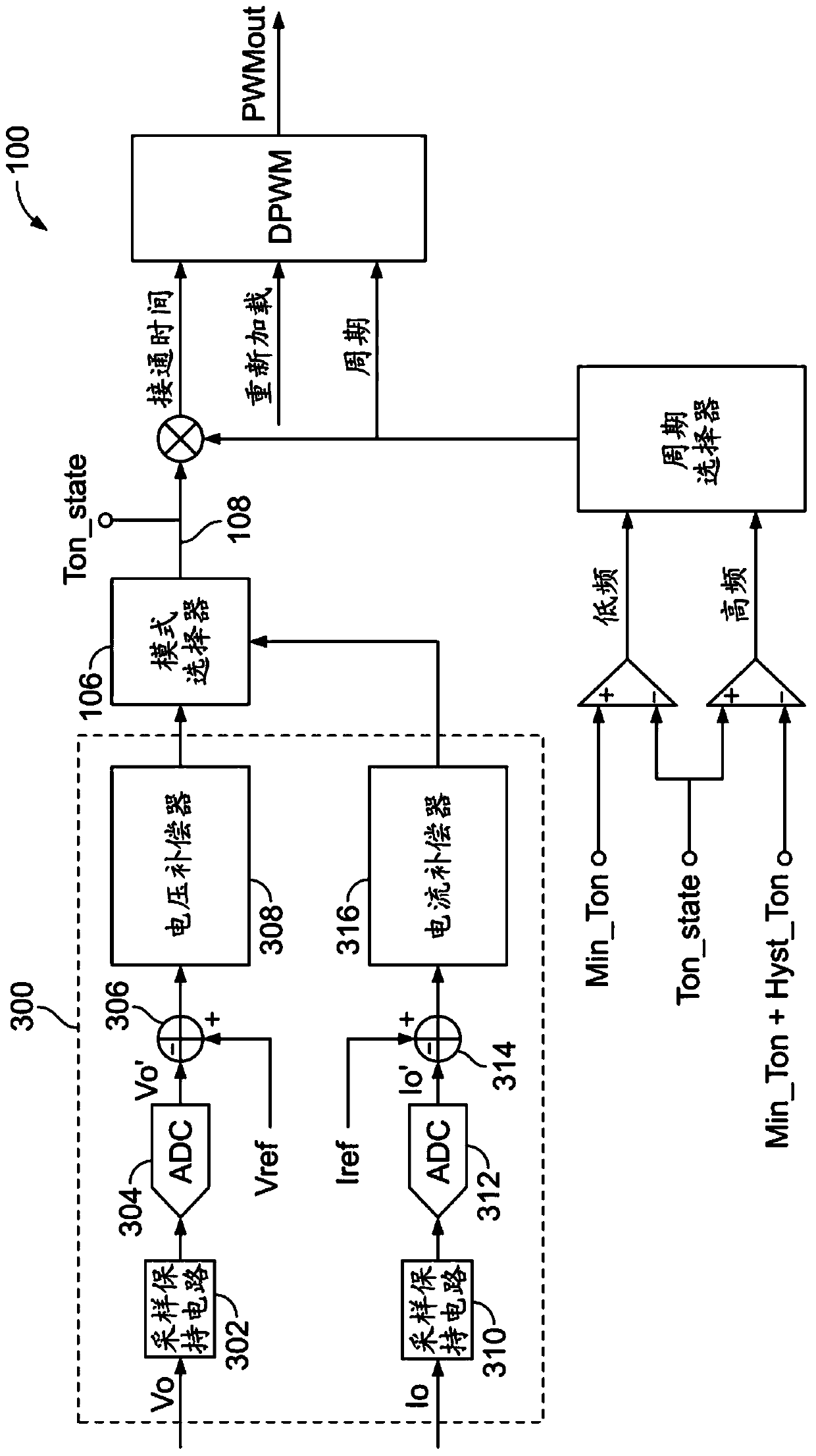

[0019] Some instrument grade and precision power supplies need to work in a relatively wide output voltage range (for example, 3V-12V). Other power supplies (also called power converters) require a wide output voltage fine-tuning range, for example, 0.8V-5V, and sometimes, when the load impedance is very low (for example, less than 1Ohm), the power converter will need to be close to zero output The voltage is working in continuous mode. The operation of the power converter at the output voltage level lower than the rated output voltage causes control problems. One of the problems with low output voltage control is the ability to maintain continuous mode when the work on time becomes smaller and smaller as the output voltage decreases. Based on multiple factors including the PWM resolution of the power converter, various propagation delays, the rise a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com