An auxiliary device for installation of ship stern tube

A technology of auxiliary device and stern tube, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long labor time, large volume and weight of the stern tube, and high labor intensity of staff, so as to reduce labor The effect of strength, improving installation efficiency and convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

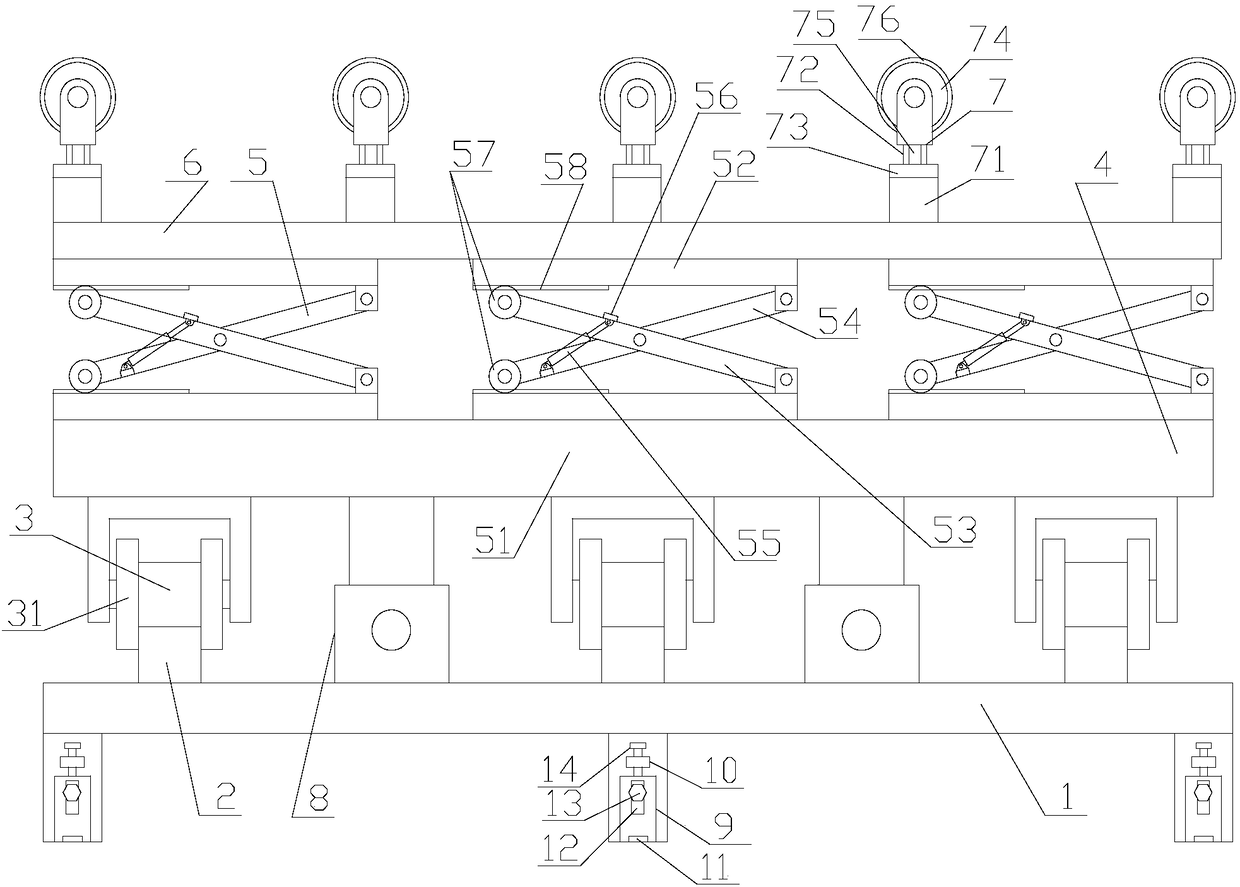

[0012] refer to figure 1 , an auxiliary device for installing a ship stern tube according to the present invention, comprising an underframe 1, a plurality of rails 2, a plurality of rollers 3, a mounting frame 4, a plurality of lifting mechanisms 5, a placement frame 6, a plurality of support wheels 7 and a plurality of first cylinders 8 , the underframe 1 is provided with a track 2, the track 2 is rested with a roller 3, the roller 3 is installed with a mounting frame 4, the underframe 1 is provided with a first cylinder 8, and the first The piston rod of cylinder 8 is fixedly connected with mounting frame 4, and described mounting frame 4 is provided with elevating mechanism 5, and described elevating mechanism 5 is equipped with placement frame 6, and described placement frame 6 is provided with support wheel 7, and described The lifting mechanism 5 comprises a lower base 51, an upper base 52, a first support frame 53, a second support frame 54, a second cylinder 55, a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com