Cooling device of film-drawing machine

A technology of cooling device and film pulling machine, which is applied in applications, household appliances, flat products, etc. It can solve the problems of diaphragm retraction, low cooling rate, and affecting the transmission accuracy of the diaphragm, so as to improve the forming accuracy and stabilize the transmission process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

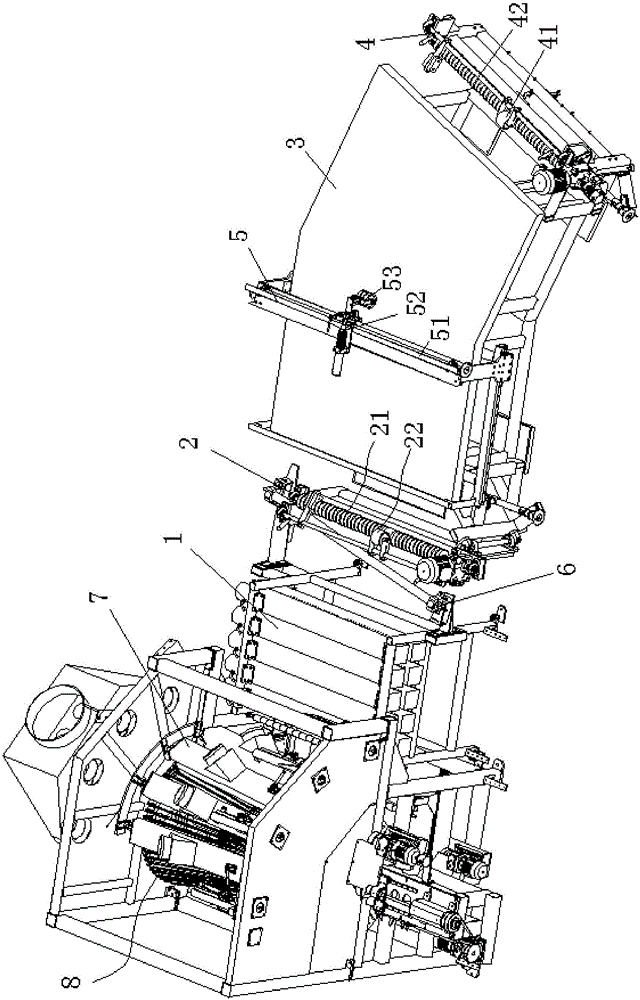

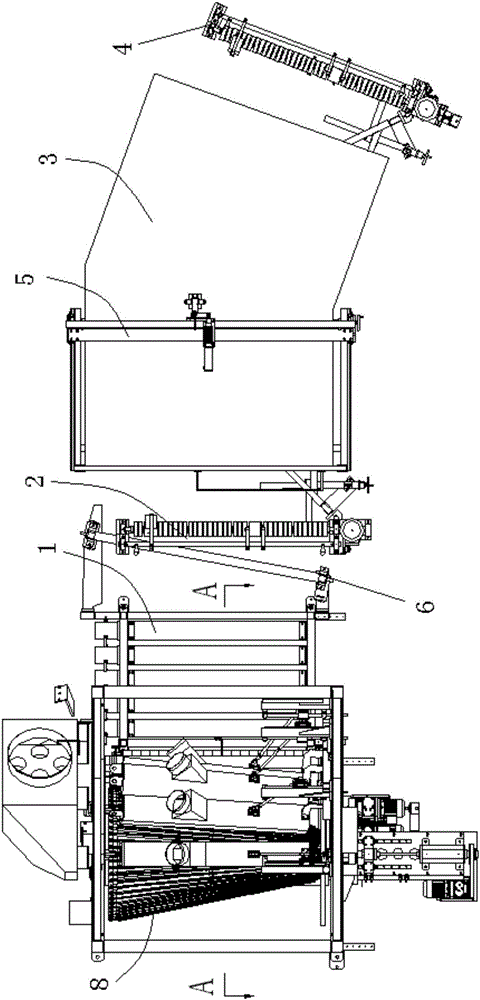

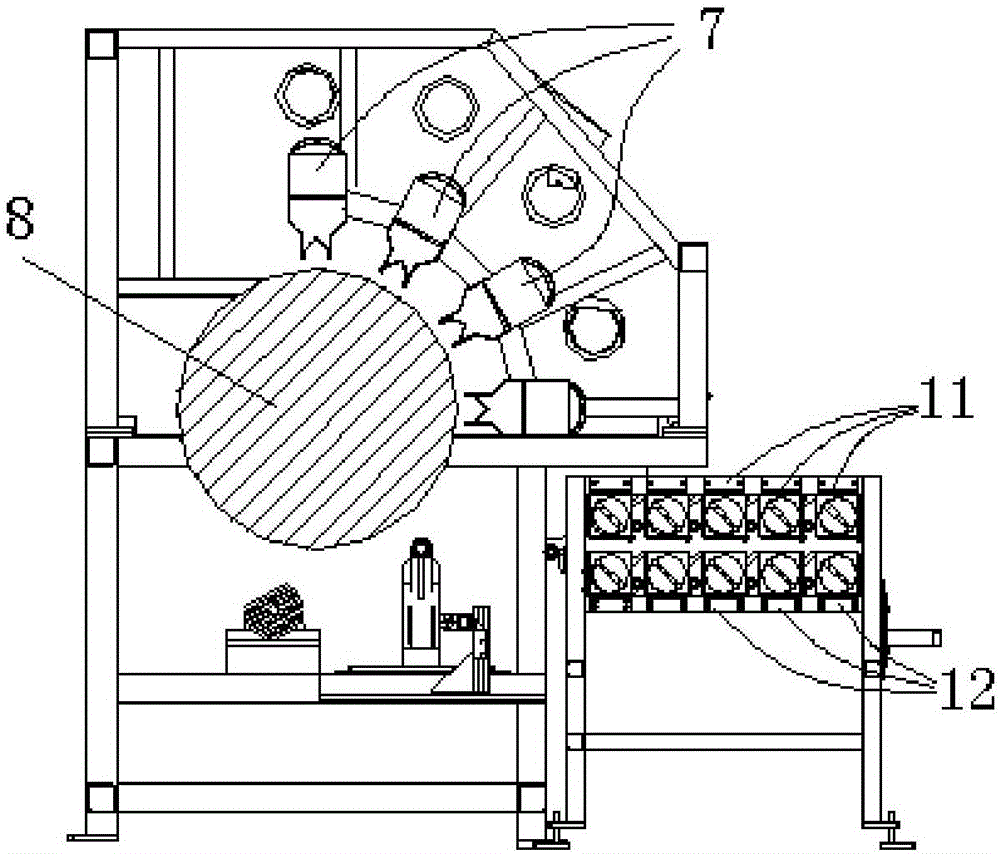

[0023] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1~3 As shown, the cooling device of a film stretching machine according to the present invention is used to cool and shape the film stretched by the forming cone roller 8, and is characterized in that: the cooling device includes arcs arranged in sequence. A cooling air grid 1, a first transmission drive mechanism 2, a cooling platform 3, and a second transmission drive mechanism 4. The first transmission drive mechanism 2 is used to pull the diaphragm to drive along the first cooling air grid 1, so The second transmission drive mechanism 4 is used for pulling the diaphragm to drive along the cooling platform 3, and the cooling platform 3 includes a cooling plate for supporting the diaphragm and a surface cooler arranged below the cooling plate.

[0025] Further, the first transmission drive mechanism 2 includes a first transmission ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com