Steering hydraulics for harvesters

A steering hydraulic and harvester technology, which is applied to the steering control, steering column, fluid steering mechanism installed on the vehicle, etc., can solve the problems of reducing the driver's work efficiency, the driver's correction force is large, and the misoperation is prone to occur. Achieve the effect of simple structure, flexible steering and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

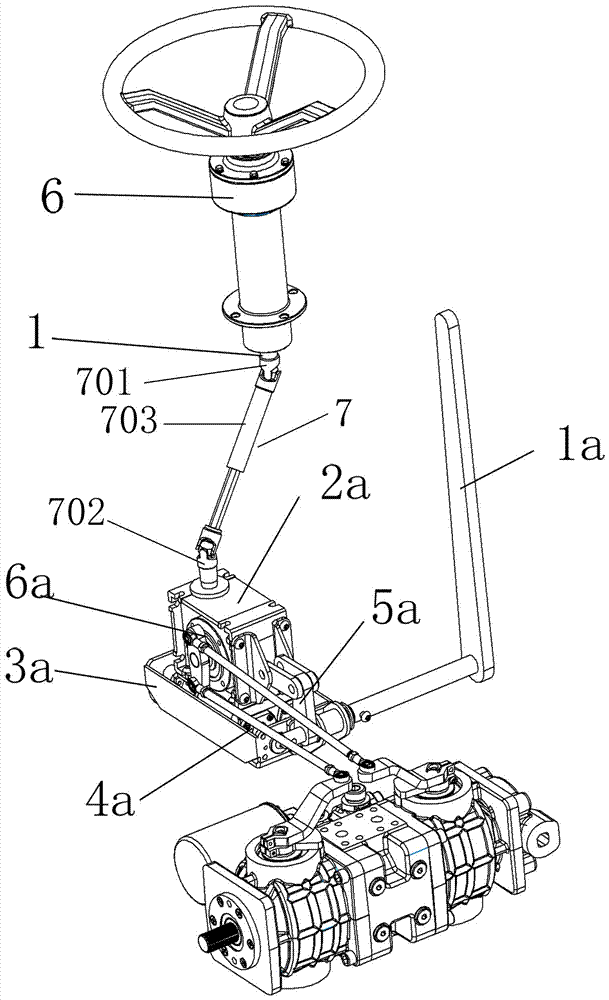

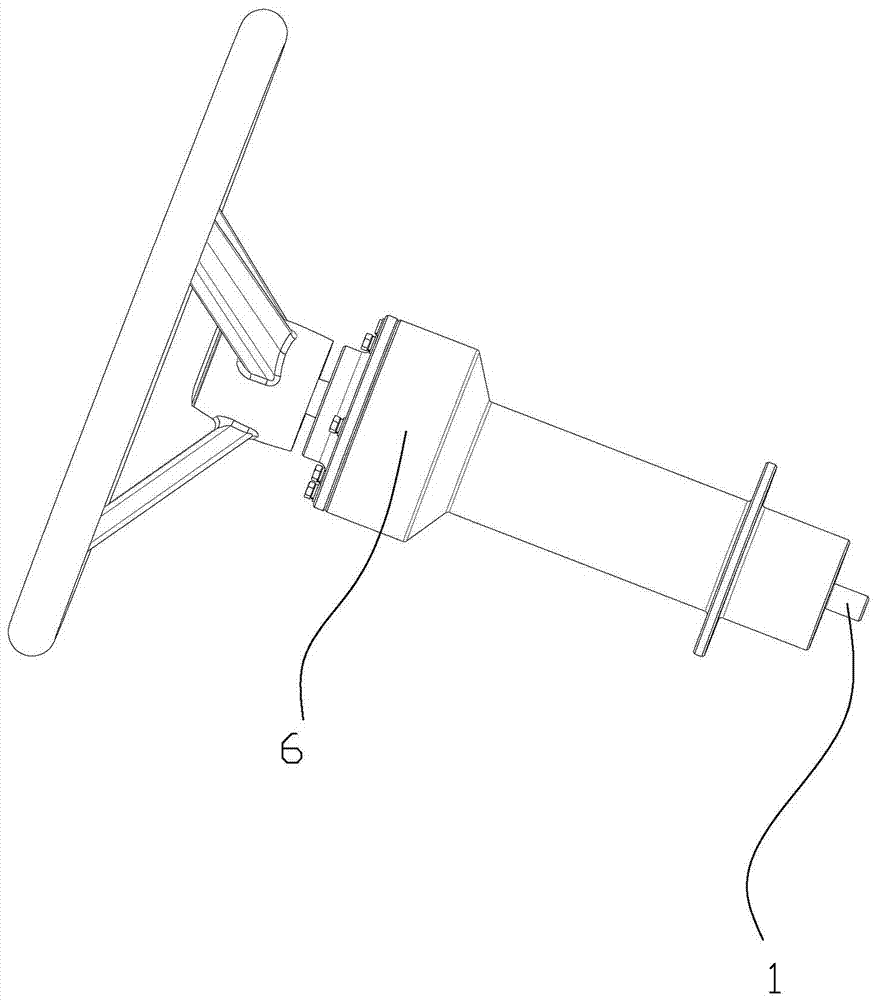

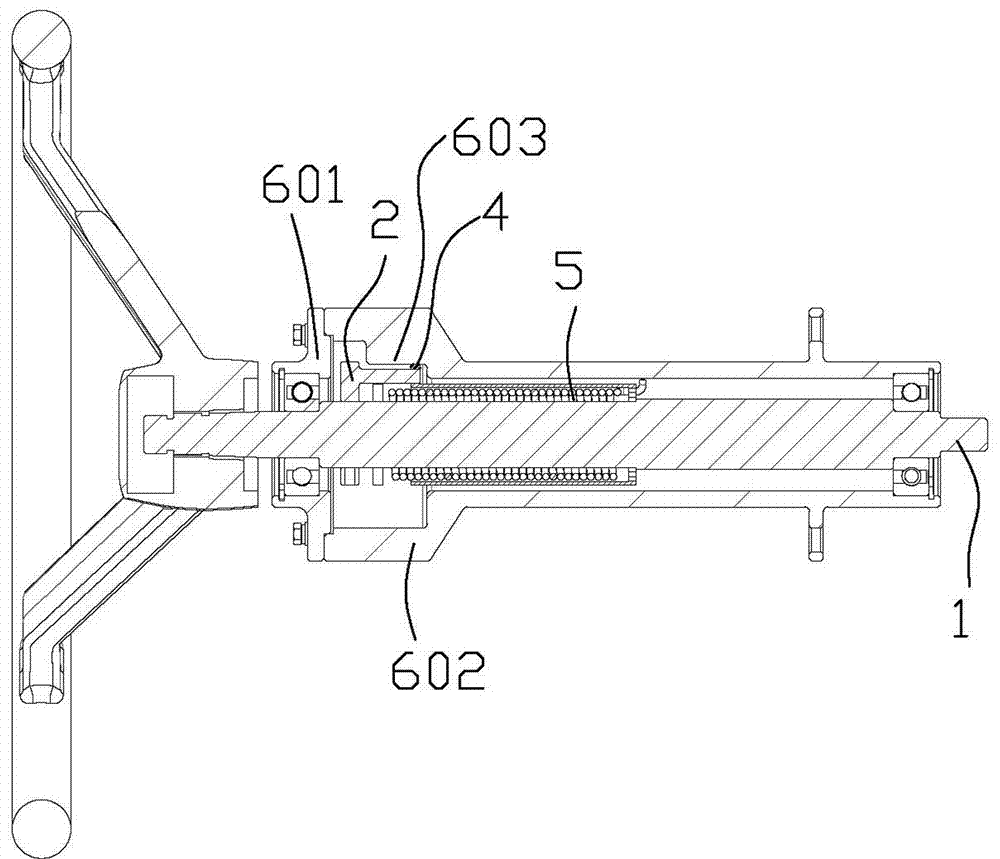

[0042] Example: such as Figure 1-Figure 9 As shown, the steering hydraulic device for the harvester includes a double variable pump, an operating handle 1a, a gearbox 2a that can move forward and backward driven by the operating handle 1a, and a mobile platform located under the gearbox 2a 3a and a moving mechanism 4a connected to the gearbox 2a, the gearbox 2a moves on the moving platform 3a through the moving mechanism 4a, the operating handle 1a and the gearbox 2a are connected through a driving connection structure 5a, The gearbox 2a is also provided with a hydraulic oil control mechanism 6a that controls the flow direction and flow rate of the hydraulic oil in the dual variable pump through the forward and backward movement of the gearbox 2a; the gearbox 2a is also provided with a steering function and Steering centering mechanism for fast centering after the steering is completed.

[0043]The mobile platform 3a is fixedly installed on the harvester, and the operating h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com