Dairy packaging cup hole detection structure

A technology for detecting structures and dairy products, used in measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

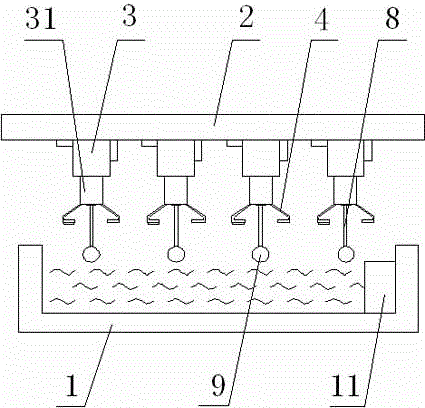

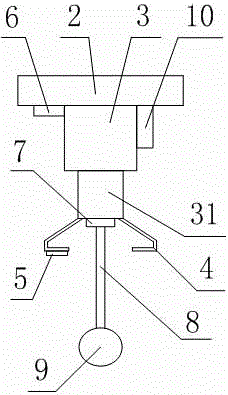

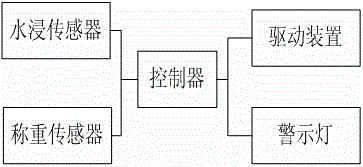

[0021] Such as Figure 1 to Figure 3 The shown dairy product packaging cup eyelet detection structure includes a water tank 1 and a transmission rod 2 passing above the water tank 1. Several driving devices 3 with the driving end 31 facing downwards are fixed on the transmission rod 2, each The driving end 31 of the driving device 3 is fixedly connected with the clamping device 4, and the bottom end of each clamping device 4 is provided with a water sensor 5, and the center position of each clamping device 4 is provided with a load cell 7. A small ball 9 is suspended by a sling 8 on the load cell 7; each driving device 3 is equipped with a controller 6 and a warning light 10, and the receiving end of the controller 6 is connected to the water sensor 5 and the load cell. 7 is electrically connected, and the control terminal of the controller 6 is electrically connected with the corresponding drive device 3 and the warning light 10; the drive device 3 is a hydraulic cylinder; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com