Automatic winding device and method thereof

An automatic winding and equipment technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of difficult work, poor product consistency, high defect rate, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

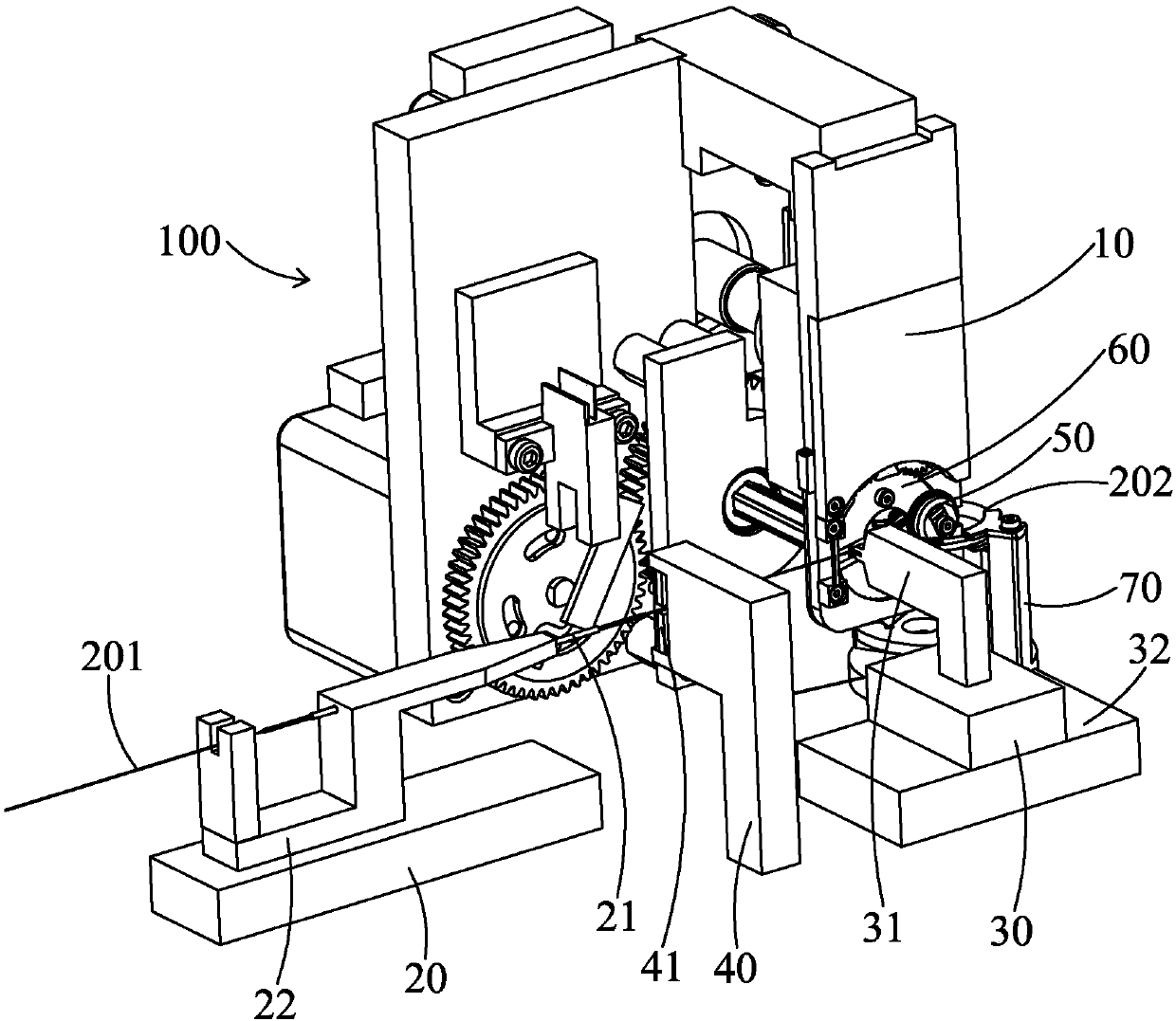

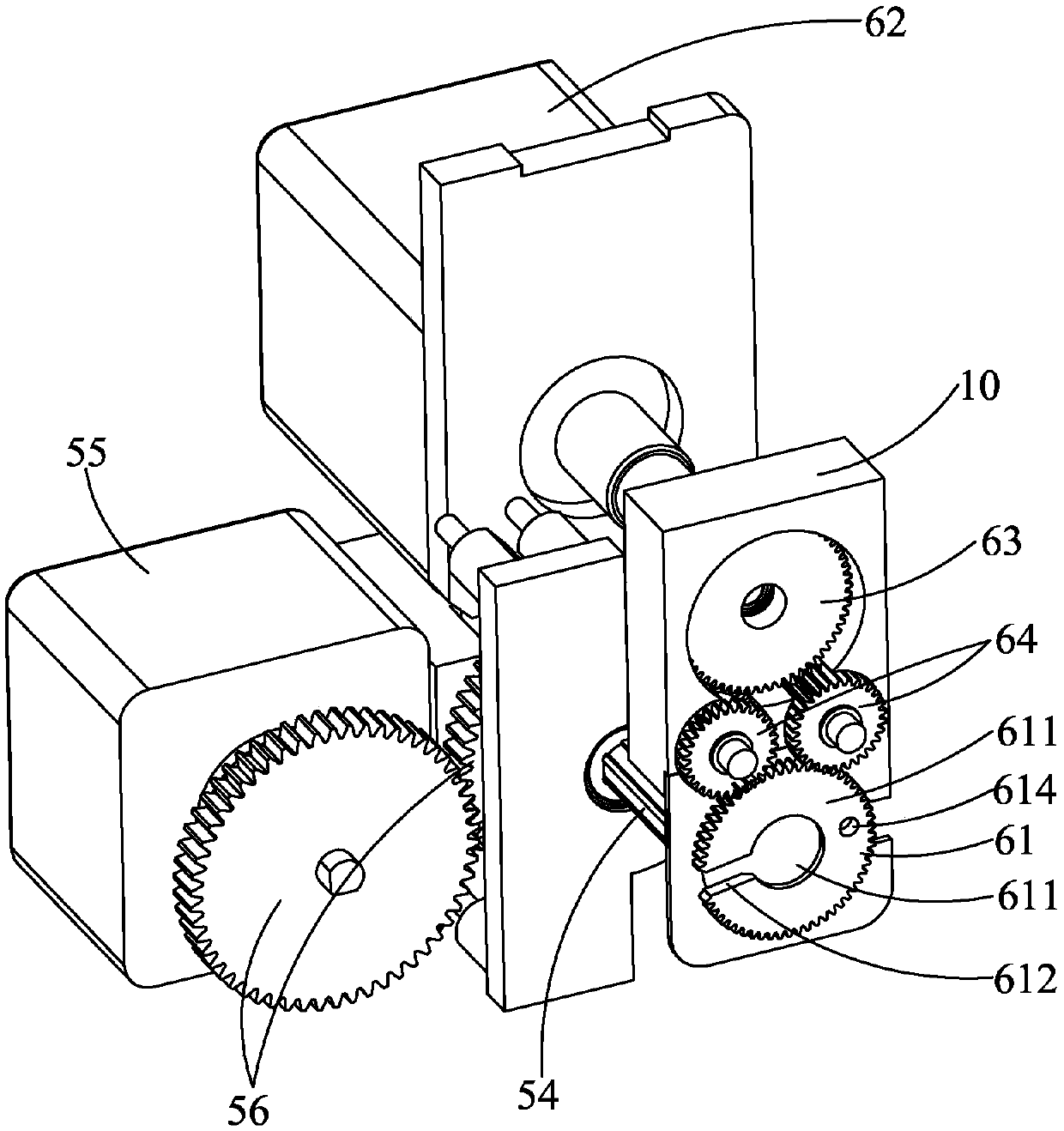

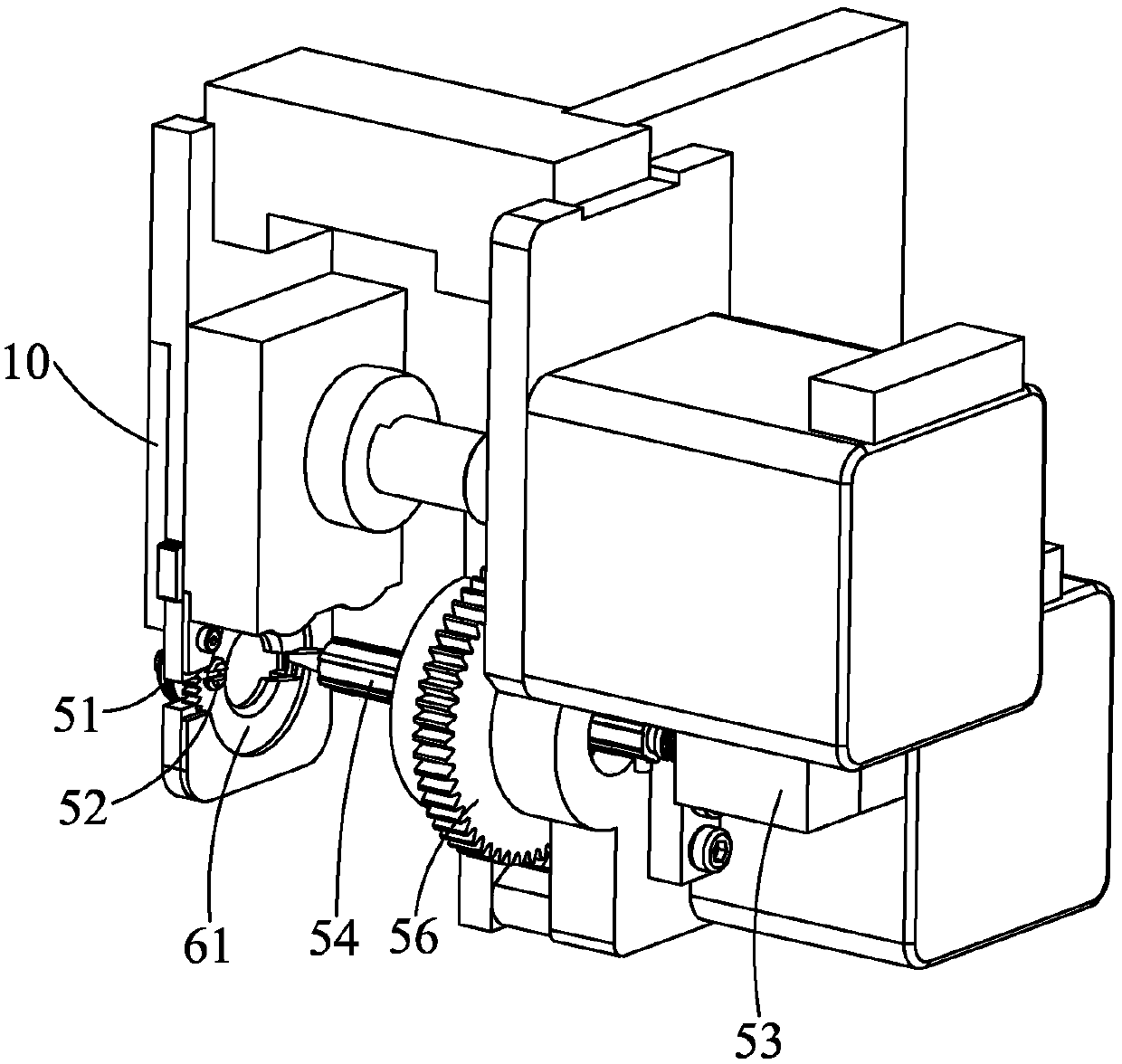

[0022] see Figure 1 to Figure 6 As shown, the automatic winding equipment 100 of the present invention is used to wind the enameled wire 201 on the magnetic iron core 202 to make a coil 200, which includes a frame 10, a wire feeding mechanism 20, a wire management mechanism 30, a wire cutting mechanism 40, a storage Wire mechanism 50, wire winding mechanism 60 and wire routing mechanism 70.

[0023] The wire feeding mechanism 20 is provided with a needle tube 21 and a displacement cylinder 22 that drives the needle tube 21 to move left and right. The enameled wire 201 is passed through the needle tube 21. By moving the needle tube 21, the head of the enameled wire 201 is passed over the wire cutting mechanism 40 and delivered to the wire management mechanism. 30 position.

[0024] The wire management mechanism 30 is provided with a clamp 31 and a movable cylinder 32 for driving the clamp 31 to move left and right and forward and backward, for clamping and positioning the ena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com