Apparatus for producing and/or packaging products in the tobacco industry

A technology of products, devices, applied in the field of devices for the manufacture and/or packaging of products of the tobacco industry, to the effect of avoiding geometric distortions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

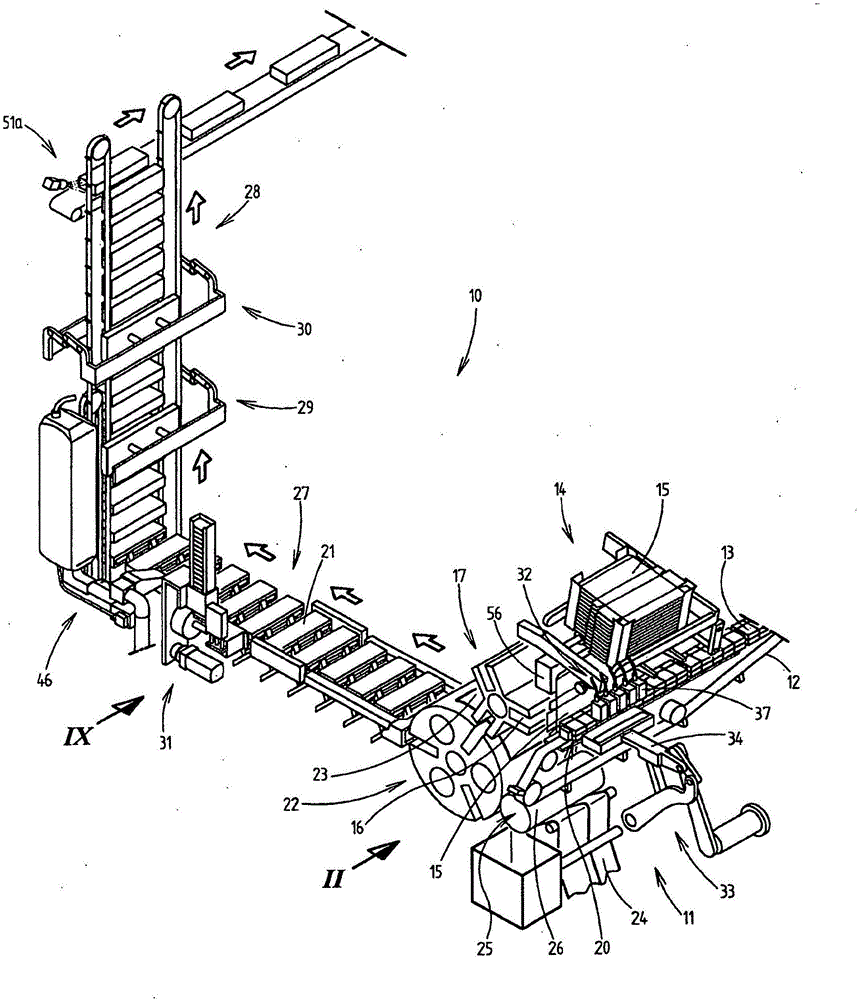

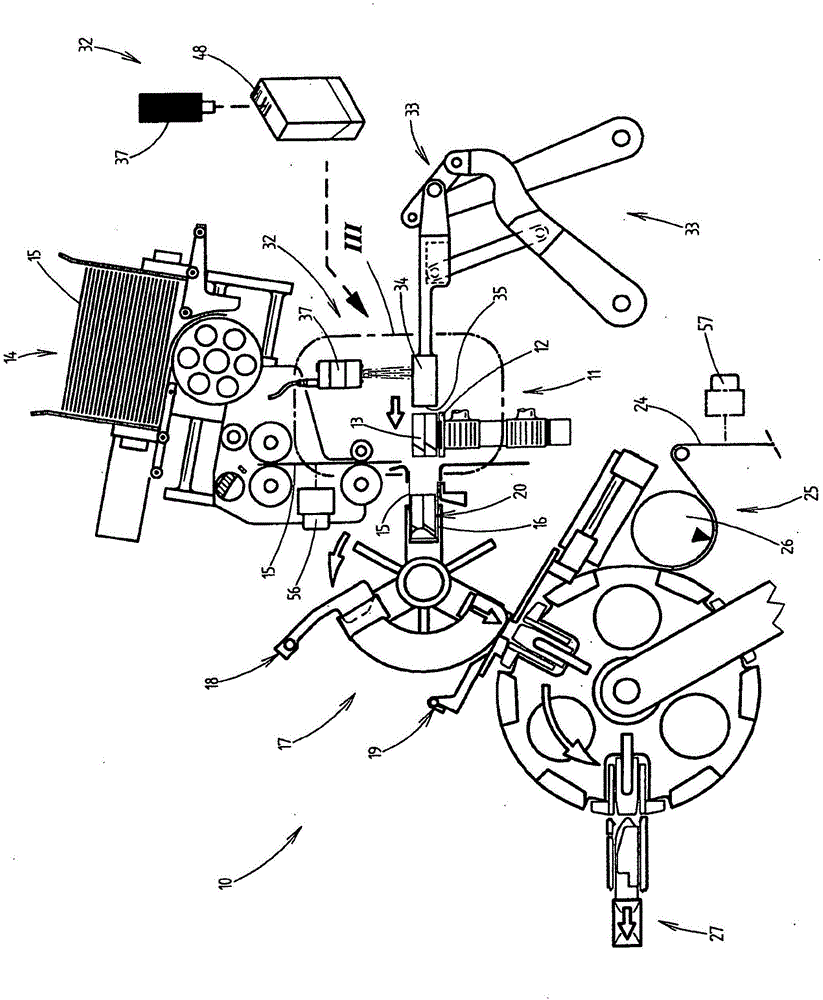

[0027] The embodiment of the invention described below relates to a so-called strapping machine or strapping machine 10 . But the invention is not limited to packing machines, but can also be used in other different devices for manufacturing and / or packing products of the tobacco industry, for example in carton packing machines, in packing machines for making individual cigarette packs, etc.

[0028] Strapping machines have long been known in the state of the art and are described, for example, in DE 10 2011 103 821 A1, the content of which is fully incorporated into this application.

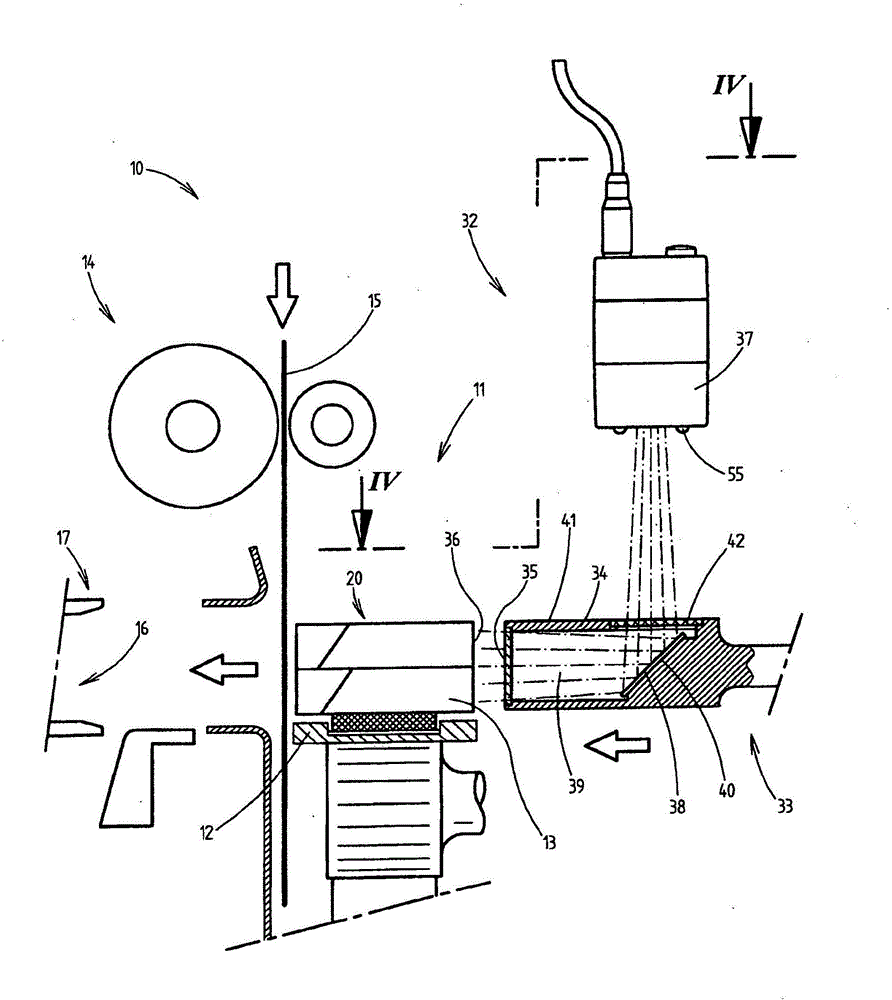

[0029] Here, such a strapping machine or said strapping machine 10 comprises a push-in station 11 in which the cigarette packs 13 grouped into a packing group 20 on a continuous conveyor 12 (currently an endless belt) are periodically successively In each case, the (cardboard) blanks 15 from the blank mechanism 14 are pushed into one prepared bag 16 of the folding turret 17 .

[0030] Previous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com