Preparation method of uranium surface coating

A technology of surface coating and metal uranium, which is applied in the direction of coating, metal material coating process, etc., can solve the problems of shielding effect, large amount of waste generation, and high requirements for substrate pretreatment, so as to prevent leakage and reduce waste generation , The effect of the simple preprocessing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

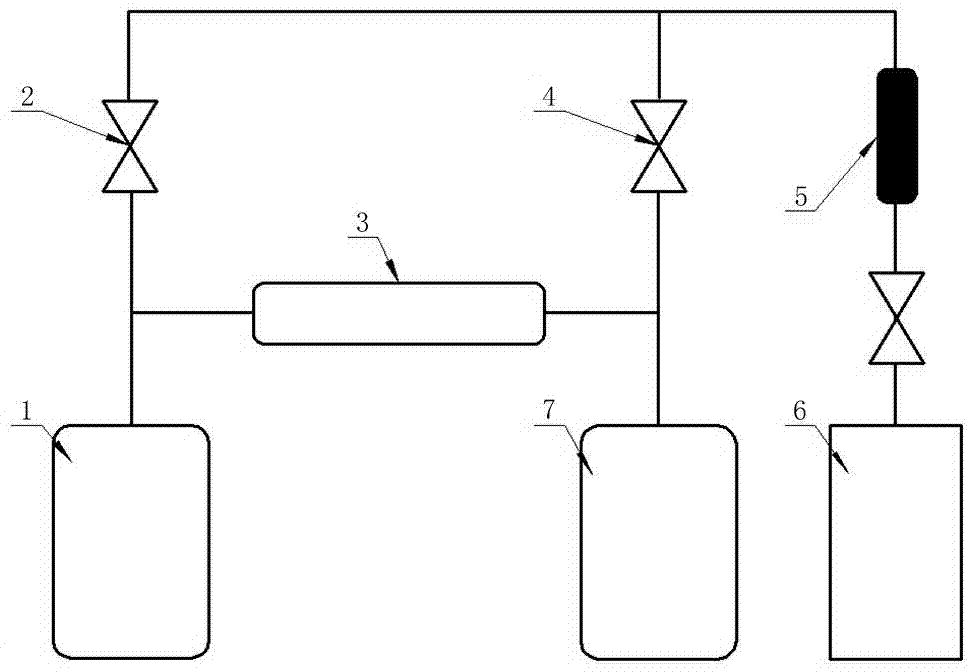

[0034] Weigh 5 grams of tin powder and 200 grams of mercury, put the weighed tin powder into the mercury, heat slowly and stir until the tin is completely dissolved, then cool naturally to room temperature for later use. Take 10 milliliters of mercury and put it into the infiltration chamber 7.

[0035] Clean the processed metal uranium plated parts with anhydrous alcohol to clean the oil stain on the surface first, and then clean it with nitric acid with a volume ratio of 1:1 between water and fuming nitric acid, until the surface of the metal uranium plated parts presents a silvery white metallic luster, accompanied by a small amount of air bubbles until produced. Take out the uranium-plated parts and clean them with absolute alcohol. Blot the residual alcohol on the surface of the uranium-plated parts with filter paper, quickly transfer to the infiltration chamber 7, encapsulate the uranium-plated parts in mercury, open the vacuum system 6, open the 1# valve 2, close the 2...

Embodiment 2

[0040] Weigh 4 grams of zinc pellets and 180 grams of mercury, put the weighed zinc pellets into the mercury, heat slowly and stir until the zinc is completely dissolved, and cool naturally to room temperature for later use. Take 10 milliliters of mercury and put it into the infiltration chamber 7.

[0041] Clean the processed metal uranium plated parts with anhydrous alcohol to clean the oil stain on the surface first, and then clean it with nitric acid with a volume ratio of 1:1 between water and fuming nitric acid, until the surface of the metal uranium plated parts presents a silvery white metallic luster, accompanied by a small amount of air bubbles until produced. Take out the uranium-plated parts and clean them with absolute alcohol. Blot the residual alcohol on the surface of the uranium-plated parts with filter paper, quickly transfer to the infiltration chamber 7, encapsulate the uranium-plated parts in mercury, open the vacuum system 6, open the 1# valve 2, close t...

Embodiment 3

[0046] Weigh 2 grams of gold and 5 milliliters of mercury, put the weighed gold into the mercury, heat slowly and stir until the gold is completely dissolved, then cool naturally to room temperature for later use. Take 10 milliliters of mercury and put it into the infiltration chamber 7.

[0047] Clean the processed metal uranium plated parts with anhydrous alcohol to clean the oil stain on the surface first, and then clean it with nitric acid with a volume ratio of 1:1 between water and fuming nitric acid, until the surface of the metal uranium plated parts presents a silvery white metallic luster, accompanied by a small amount of air bubbles until produced. Take out the uranium-plated parts and clean them with absolute alcohol. Blot the residual alcohol on the surface of the uranium-plated parts with filter paper, quickly transfer to the infiltration chamber 7, encapsulate the uranium-plated parts in mercury, open the vacuum system 6, open the 1# valve 2, close the 2# valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com