Sand manufacturing device capable of conducting mobile operation

A technology for operation and sand making machine, applied in the direction of solid separation, sieve, grille, etc., can solve the problems of low sand production rate, easy damage to sand production equipment and high transportation cost of sand and gravel mixed raw materials, so as to improve the sand production rate. , reduce wear and tear, the effect of high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

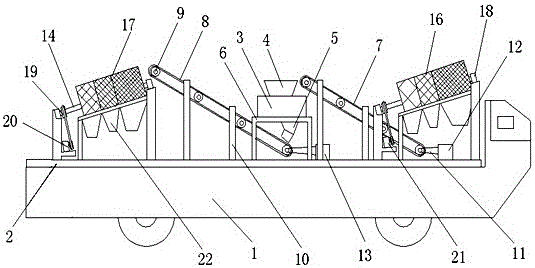

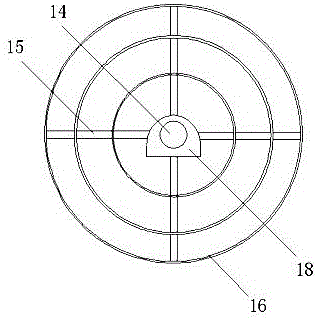

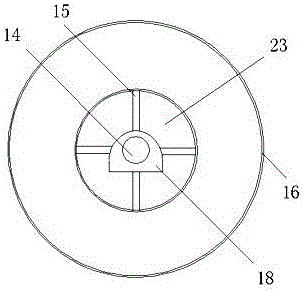

[0018] Embodiment 1: A sand making device capable of mobile operation, mainly comprising a carrier vehicle 1, a mounting plate 2, a sand making machine 3, a conveyor belt 1 7, a conveyor belt 2 8, a trommel 16, a trommel 2 17, and It is characterized in that: the installation plate 2 is arranged on the carrying vehicle 1, and the support frame 6, the support rod 10, the motor one 12, and the motor two 13 are arranged on the installation board 1. When sand making equipment is required at the construction site, the The carrying vehicle can be driven to the construction site, and the transportation is convenient, which reduces the transportation cost of the sand making equipment. Feeding port 4 and discharge port 5 are arranged on the top, the conveyor belt-7 is arranged on the support rod 10, and the roller shaft 9 is arranged on the conveyor belt-7, and one end thereof is arranged at the bottom of the trommel-16, The other end is close to the feeding port 4, and the sand-making...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com