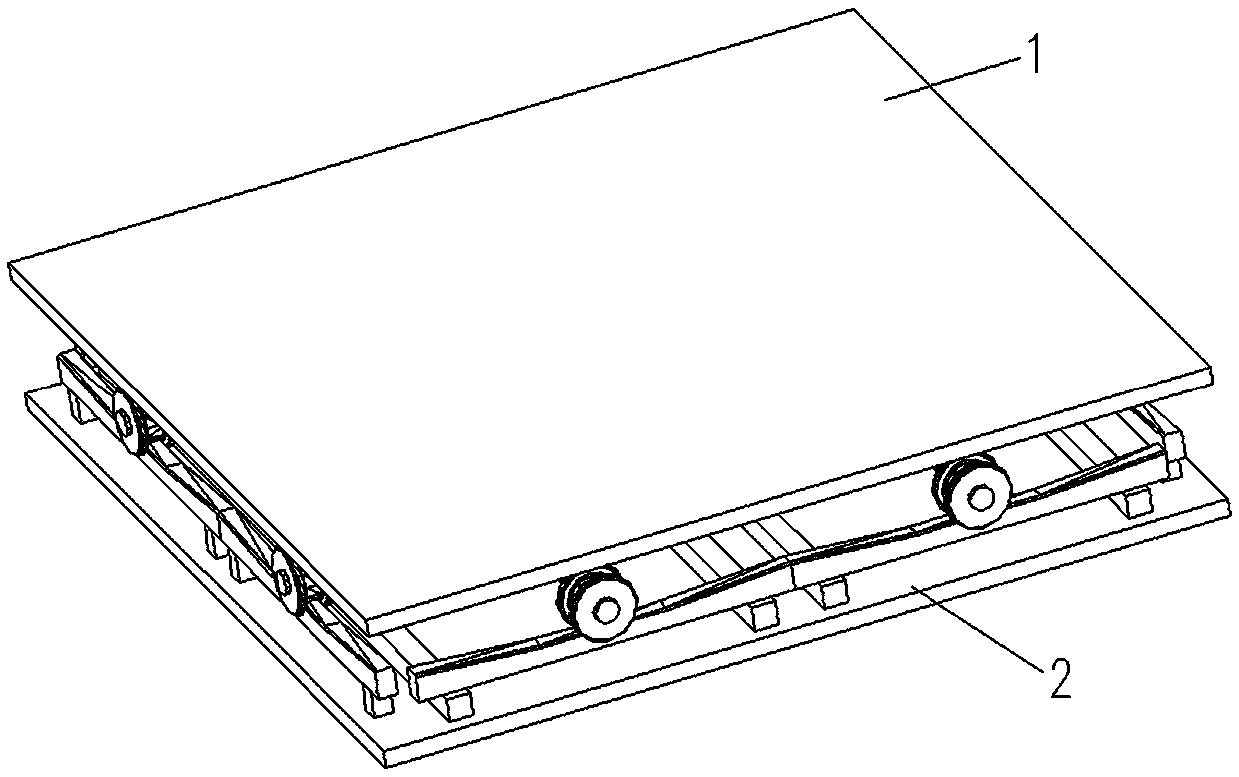

Design method of a two-way roller type vibration isolation device

A design method and roller-type technology, applied in the direction of shock absorbers, mechanical equipment, springs/shock absorbers, etc., can solve the problems of large occupied space and complex structure of the roller isolation device, so as to reduce the occupied space and have a simple structure. , the effect of obvious social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

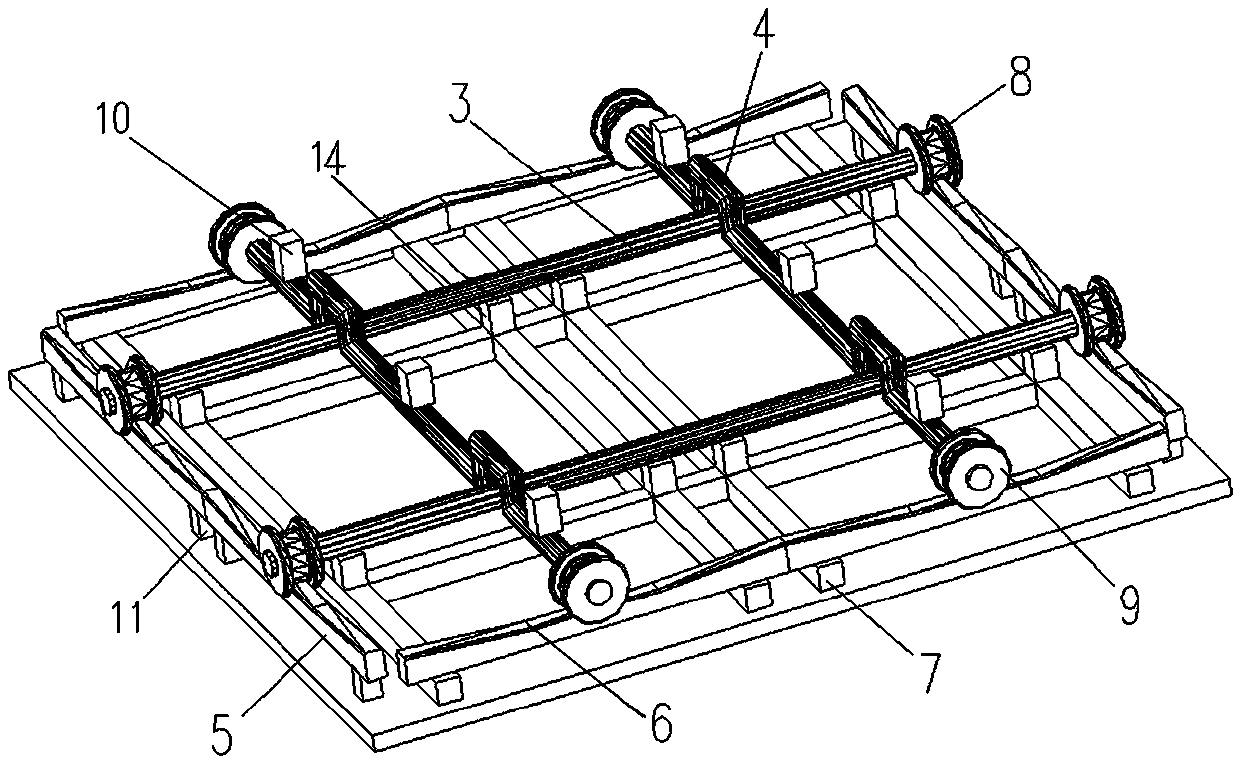

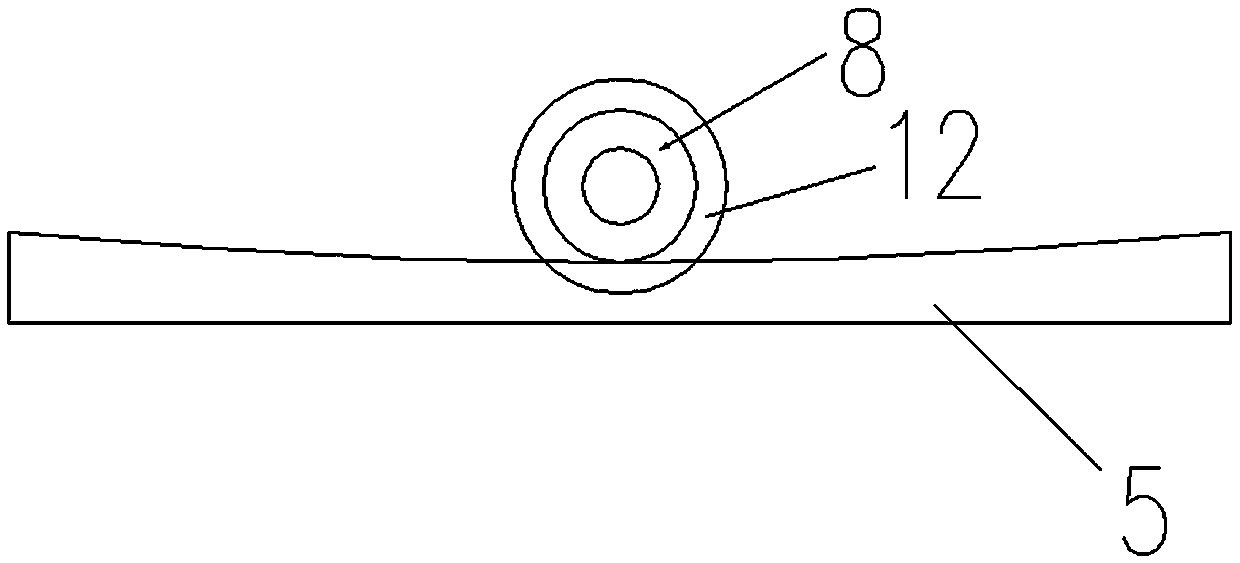

[0066] In this embodiment, the upper surface of the fixed curvature track 5 is provided with two sections of smooth arc along its long axis; the upper surface of the floating curvature track 6 is provided with two sections of smooth arc along its long axis; Adjusting the radius of curvature of the fixed curvature track 5 and the floating curvature track 6 can realize shock isolation effects in two directions. Connected on the fixed curvature track 5; the floating track rollers 9 correspond to the smooth arc surface on the floating track 6, there are two pairs, and are slidably connected on the floating track 6.

[0067] In the present embodiment, a long fixed track wheel shaft 3 is connected between each pair of fixed track rollers 8; a long floating track wheel shaft 4 is connected between each pair of floating track rollers 9; the fixed track wheel shaft 3 and The floating rail axle 4 is located in the same horizontal plane and is arranged in a cross; in order to reduce the ...

Embodiment 2

[0096] like Figure 11-18 In this embodiment, the upper surface of the fixed curvature track 5 is provided with two sections of smooth arc along its long axis; the upper surface of the floating curvature track 6 is provided with two sections of smooth arc along its long axis; Adjusting the radius of curvature of the fixed curvature track 5 and the floating curvature track 6 can realize shock isolation effects in two directions. Connected on the fixed curvature track 5; the floating track rollers 9 correspond to the smooth arc surface on the floating track 6, there are two pairs, and are slidably connected on the floating track 6.

[0097] In this embodiment, each fixed track roller 8 is connected to a fixed track wheel shaft 3 in the axial direction; each floating track roller 9 is connected to a floating track wheel shaft 4 in the axial direction.

[0098] There is no contact between each fixed track axle 3 and the floating track axle 4.

[0099] In this embodiment, in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com