Sanitary type quick coupler

A hygienic, male joint technology, applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, passing components, etc., can solve the problem that the joint form cannot be applied to pipes, etc., and achieve the effect of online cleaning and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

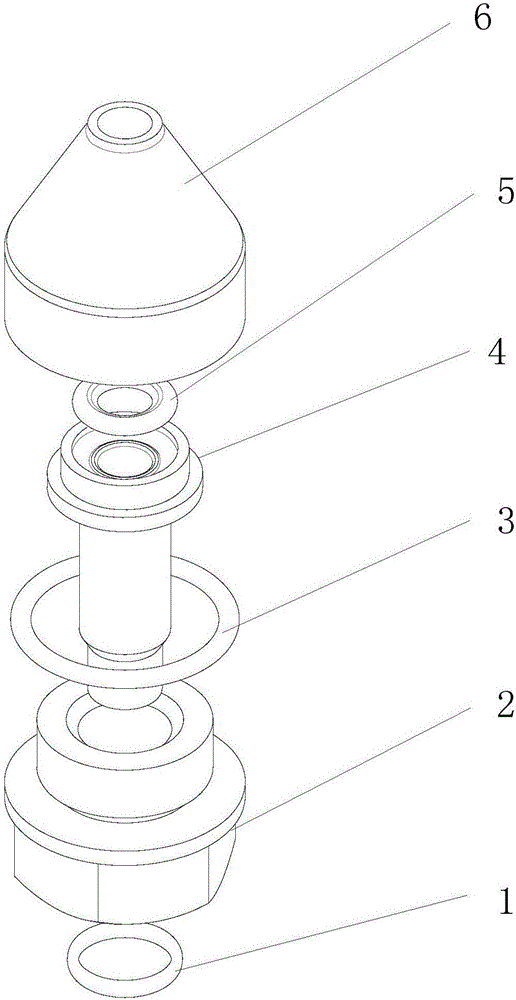

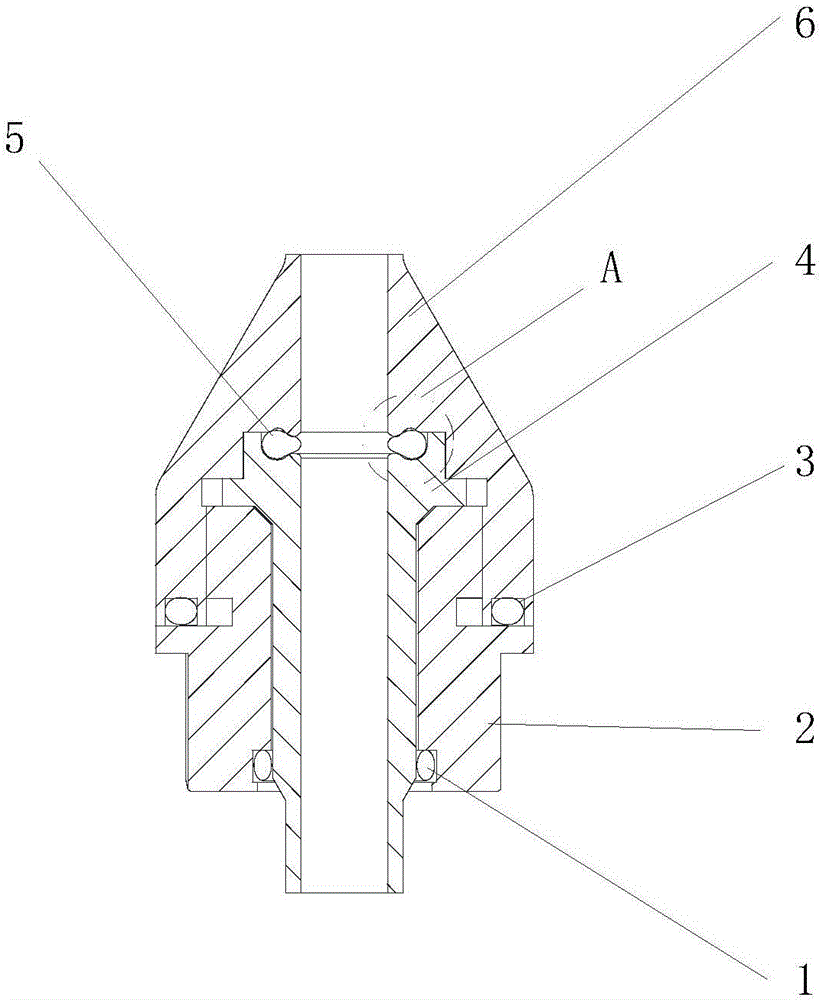

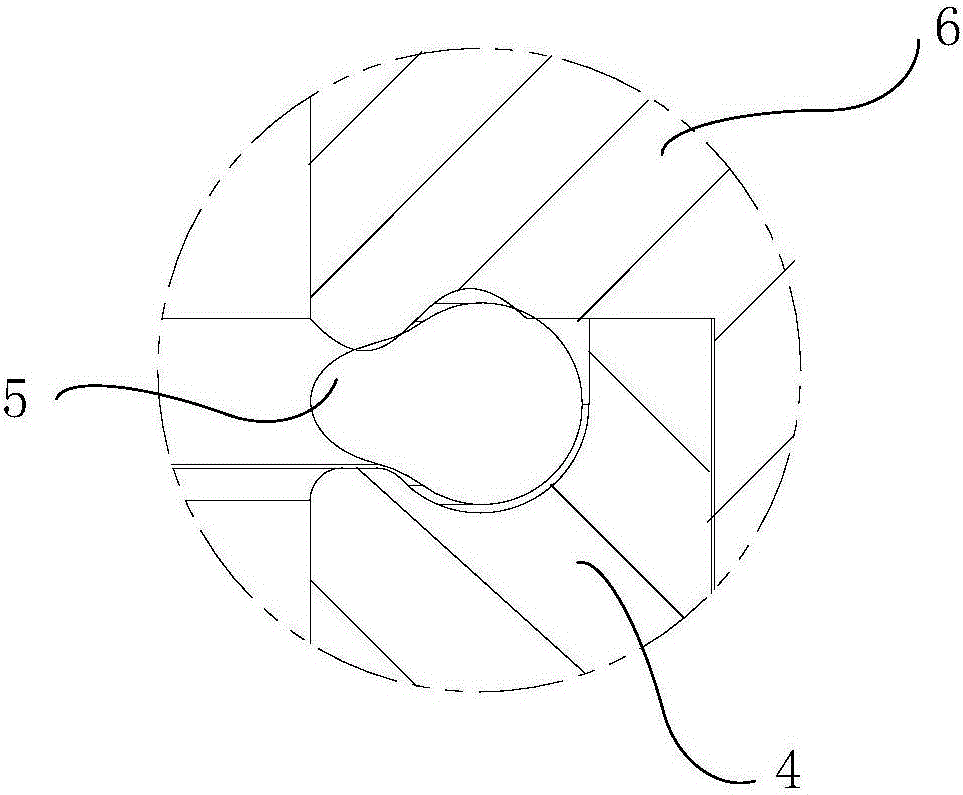

[0047] This embodiment provides a sanitary quick connector, such as Figure 1~3 As shown, it includes a first O-ring 1, a nut 2, a second O-ring 3, a male connector 4, a third O-ring 5 and a female connector 6; the male connector 4 is obtained from the The bottom of the female connector 6 is inserted into the hollow part, and the third O-ring 5 is inserted into the inner part of the female connector 6 to achieve a sealed connection; the nut 2 is inserted from the bottom of the male connector 4, and the The bottom of the female joint 6 is screwed, and the second O-ring 3 is sealed with the bottom of the female joint 6, and the first O-ring 1 is tightly sealed with the lower part of the male joint 4 .

[0048] Specifically, such as Figure 4 As shown, the nut 2 is a hollow structure, and the nut 2 includes a first equal-diameter straight pipe 201, a first equal-diameter flange 203 and a second equal-diameter straight pipe 204 connected in sequence, and the first equal-diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com