A Calculation Method for Solving the Shading Amount of Axial Sectional Profile in Vertical Projection

A technology of vertical projection and calculation method, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as thread parameter measurement errors, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

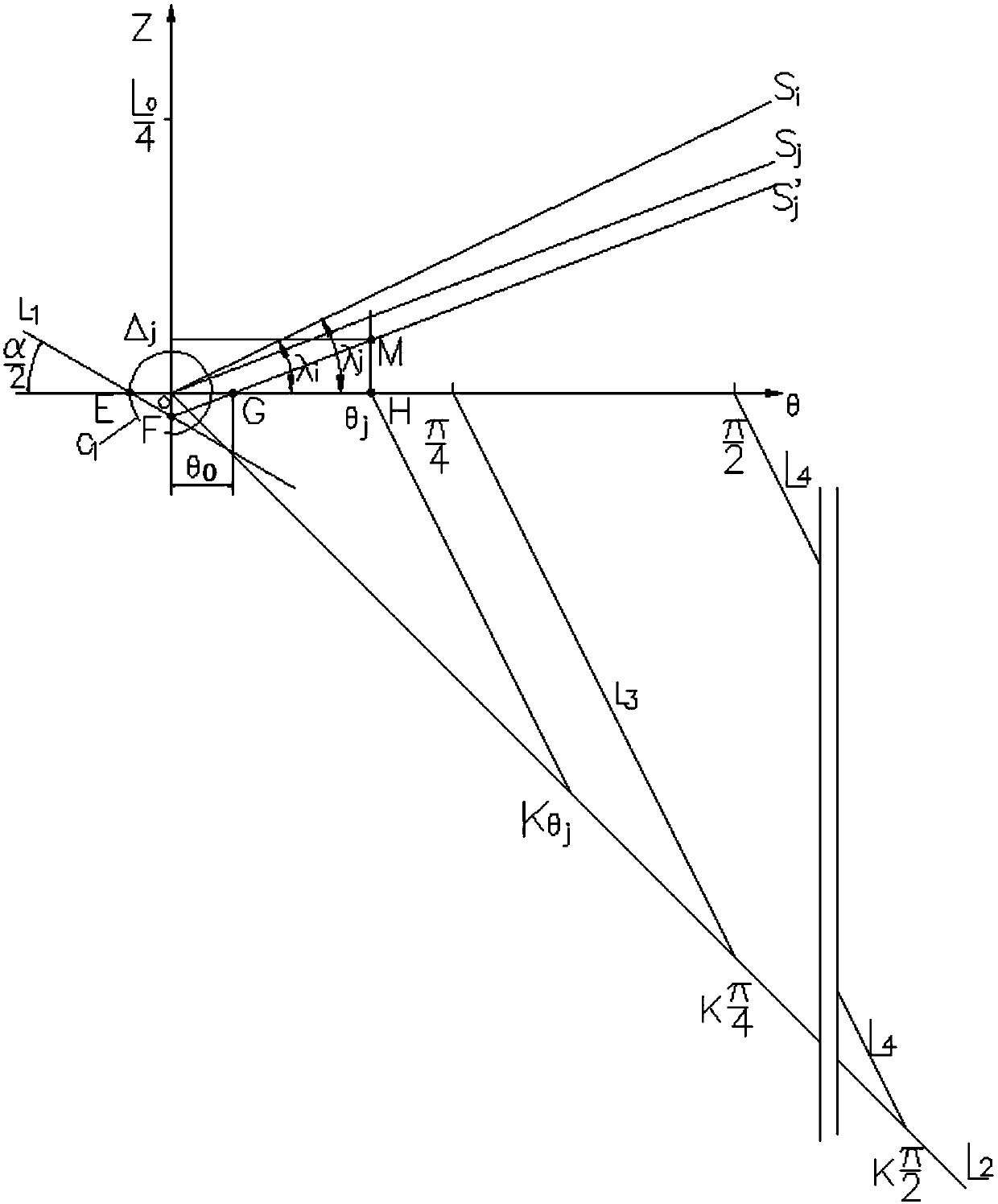

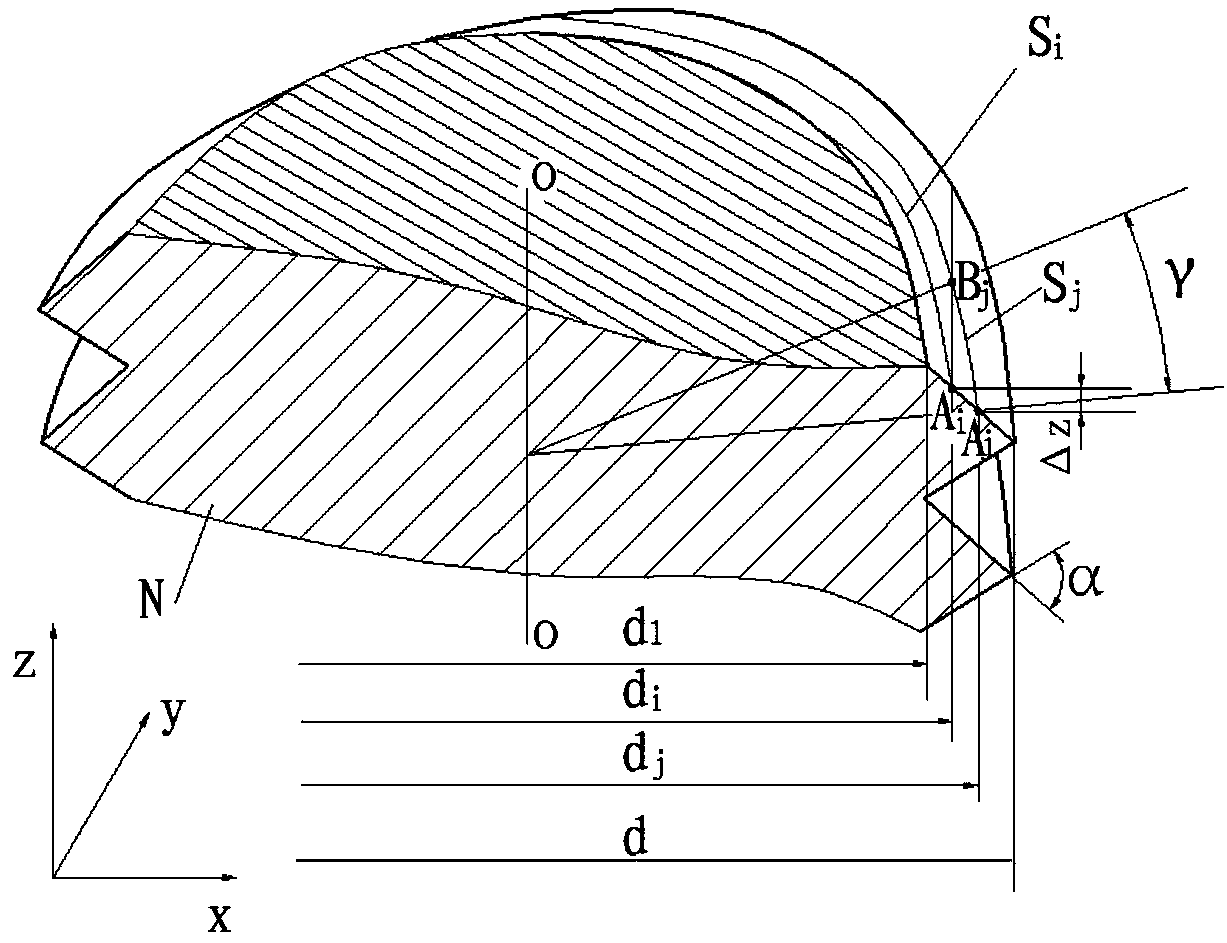

[0047] Take a certain flank of a cylindrical triangular thread as an example, such as figure 2 As shown, N is the shaft section through the cylindrical thread axis OO, S i and S j is any two helical lines on the ipsilateral tooth profile (d i and d j Cylindrical helix S i and S j diameter, and d i j ), which respectively intersect A with the axial section N i and A j , due to the tooth form angle α, on the axial section N, point A i has a z-coordinate greater than point A j The z coordinate, when the helix S j Point A on the axial section j Turn along its helix angle through the extended helix angle γ angle to be B j , the helix S j up and point A i point B in the same direction as the coordinate x j It will be because its z coordinate value is greater than A i , and form a occlusion; all gyration diameters are greater than d i Helix S j can result in A i Due to the different types and sizes of thread angles α and lead angles are different, and there are man...

Embodiment 2

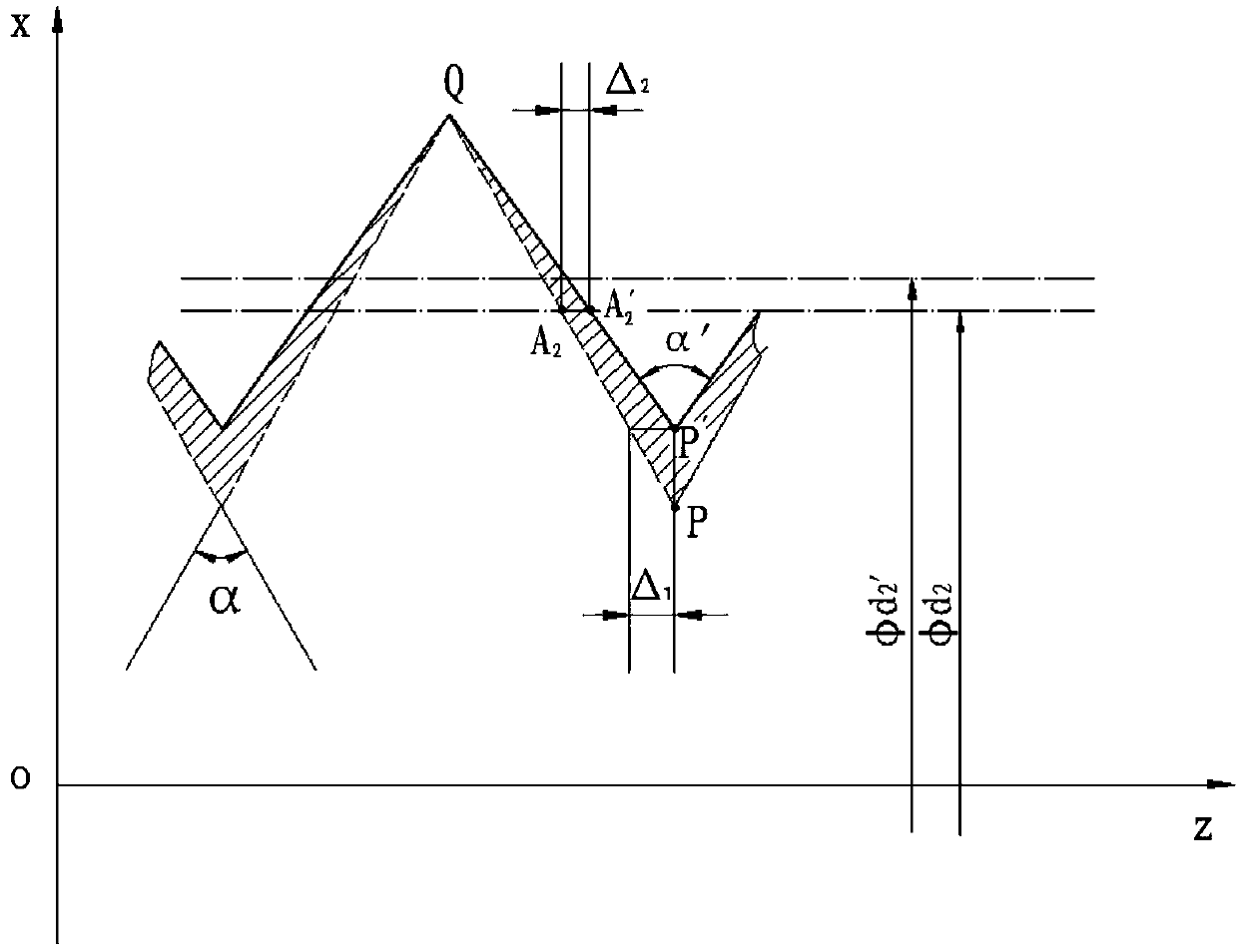

[0049] Take the triangular thread with straight profile as an example, such as image 3 As shown, for a flank tooth profile QP′ obtained by vertical projection, the middle point A 2 ′ and P′ at the root of the tooth extend the helical surface occlusion Δ 2 and Δ 1 , recover the real point A on the tooth profile by calculating the difference of the z coordinates 2 and P, the crown Q cannot be occluded, as long as it is simply connected to QA 2 P, the real tooth profile can be approximated.

[0050] The present invention is a calculation method for calculating the amount of tooth shape occlusion of an axial section when vertical projection is used. The method can be used to estimate the amount of tooth shape occlusion at each diameter of the thread when vertical projection is used to measure threads, and improve the accuracy of tooth shape parameters when vertical projection is used for measurement. accuracy. In particular, the estimation of the occlusion at the tooth root ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com