Groove depth measurement apparatus and method for measuring groove depth

A technology for measuring devices and measuring tanks, which is applied in the direction of measuring devices and instruments, and can solve problems such as difficult online measurement and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

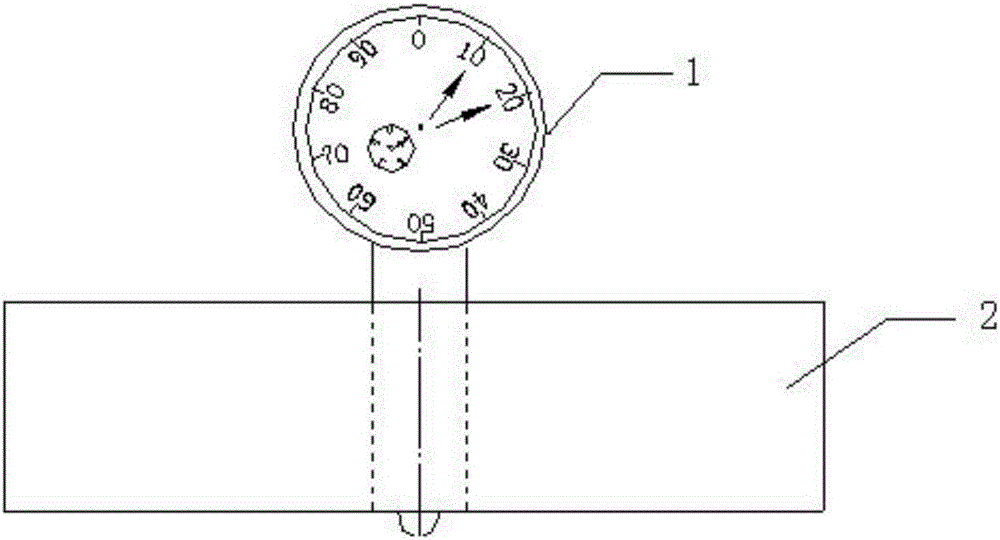

[0024] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. A groove depth measuring device in this embodiment includes a measuring instrument 1 and an instrument groove block 2;

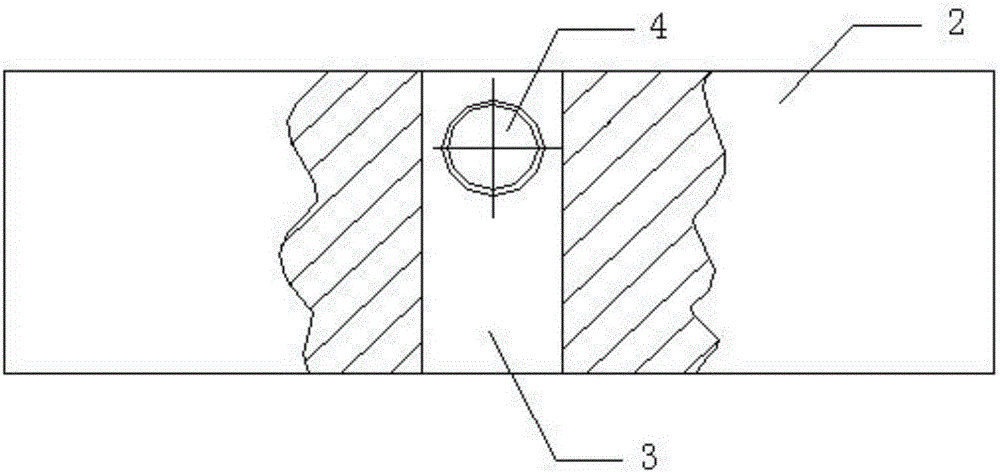

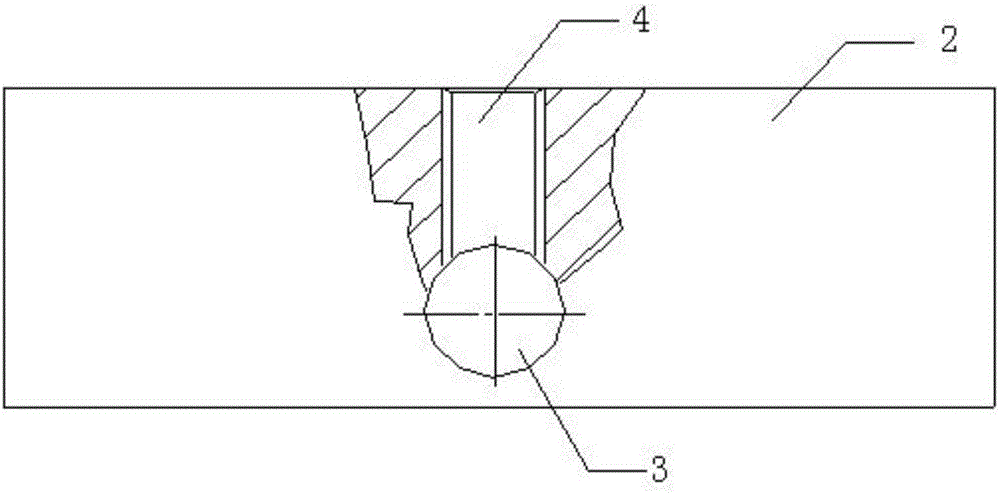

[0025] The instrument tank block 2 is a cube structure;

[0026] The top surface of the instrument tank block 2 is provided with a through hole 3 penetrating the bottom surface, and a measuring instrument 1 is inserted in the through hole 3;

[0027] A threaded hole 4 communicating with the through hole 3 is provided on the side of the instrument tank 2 , and a screw rod for fixing the measuring instrument 1 is screwed into the threaded hole 4 .

[0028] This implementation mode designs a special groove depth measuring device for the current problem that the depth of the oil groove on the end face is difficult to achieve online measurement on the machine tool and the efficiency is low. After the oil groove on the end face is processed, it can be measured online on the machine tool. When the unqualifi...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the meter tank block 2 is a cuboid. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the perpendicularity between the through hole 3 and the bottom surface is not greater than 0.1 mm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com