Method for measuring the level of crude oil in the outer floating roof crude oil storage tank

A liquid level height, crude oil storage tank technology, applied in the liquid level indicator of physical variable measurement, etc., can solve the problems of easy accumulation of large sludge, measurement error, and blockage of the lower end flow hole of the storage tank metering tube, etc., to achieve the equipment structure Simple, reduce measurement error, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment is used to illustrate the method for measuring the liquid level of crude oil in an outer floating roof crude oil storage tank according to the present invention.

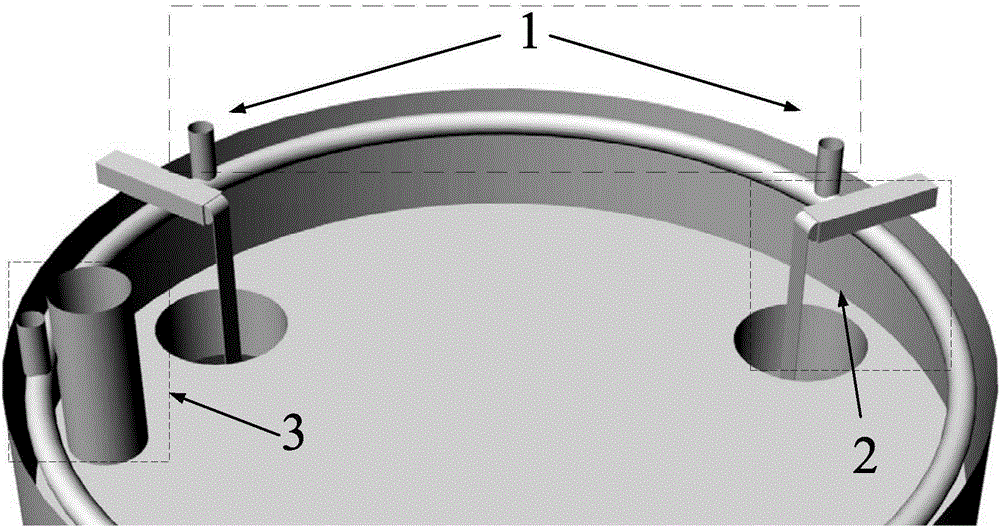

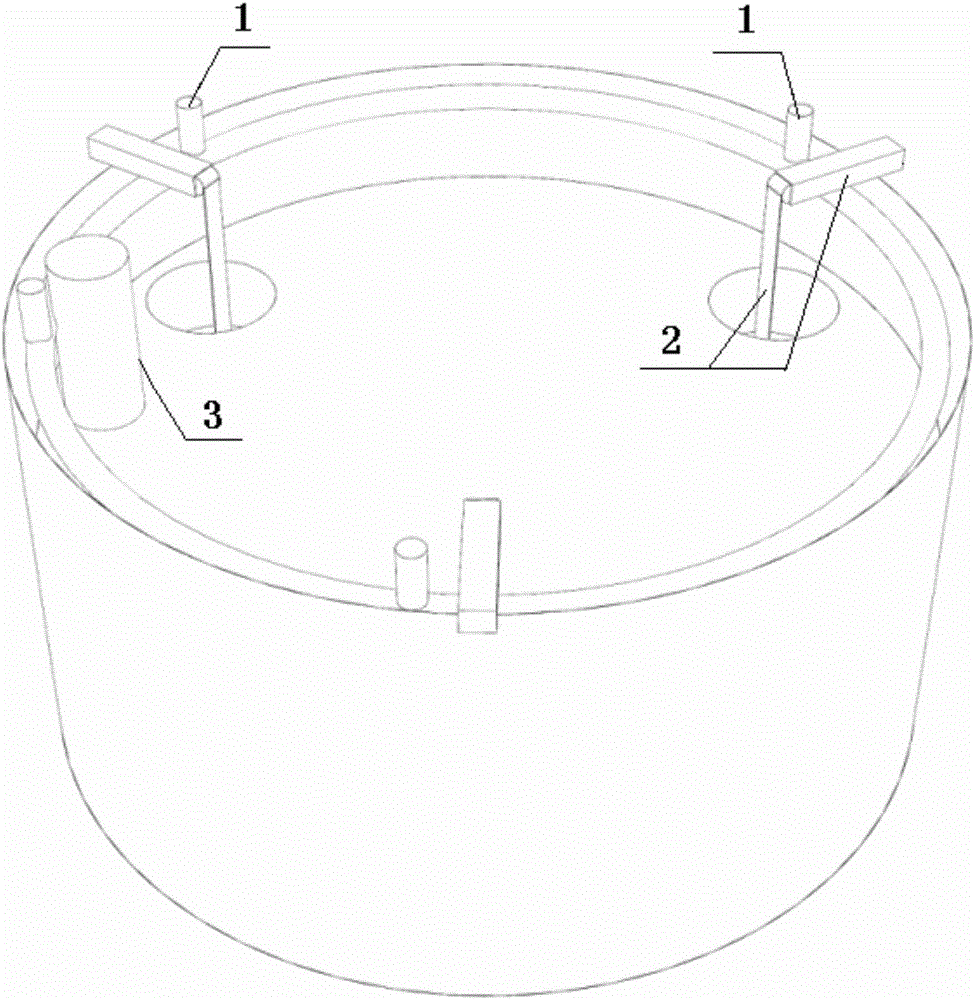

[0039] Such as figure 1 and figure 2As shown, the external floating roof crude oil storage tank equipment used when measuring the crude oil liquid level in the external floating roof crude oil storage tank includes: floating plate liquid level calibration device 2, which is used to measure the liquid level at the sampling port of the floating plate of the storage tank; The metering device 3 is used to measure the liquid level in the metering tube of the metering device 3; the zero point calibration device 1 is used to measure the top of the tank wall corresponding to the floating plate sampling port and the tank wall corresponding to the metering tube of the storage tank The height difference at the top.

[0040] Wherein, the zero point calibration device 1 includes 3 U-shaped tubes marked ...

Embodiment 2

[0046] This embodiment is used to illustrate the method for measuring the liquid level of crude oil in an outer floating roof crude oil storage tank according to the present invention.

[0047] Such as figure 1 and figure 2 As shown, the external floating roof crude oil storage tank equipment used when measuring the crude oil liquid level in the external floating roof crude oil storage tank includes: floating plate liquid level calibration device 2, which is used to measure the liquid level at the sampling port of the floating plate of the storage tank; The metering device 3 is used to measure the liquid level in the metering tube of the metering device 3; the zero point calibration device 1 is used to measure the top of the tank wall corresponding to the floating plate sampling port and the tank wall corresponding to the metering tube of the storage tank The height difference at the top.

[0048] Wherein, the zero point calibration device 1 includes two U-shaped tubes mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com